Wire drawing machine and wire drawing technology for automobile stepping bar surface wire drawing treatment

A technology of surface drawing and drawing machine, which is applied in the direction of machine tools, manufacturing tools, and grinding workpiece supports suitable for grinding workpiece planes. It can solve the problems of unstable drawing effect, low efficiency, and no guarantee of drawing quality. Convenient card, good interlocking, reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

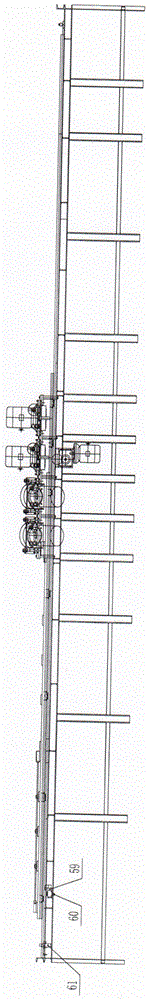

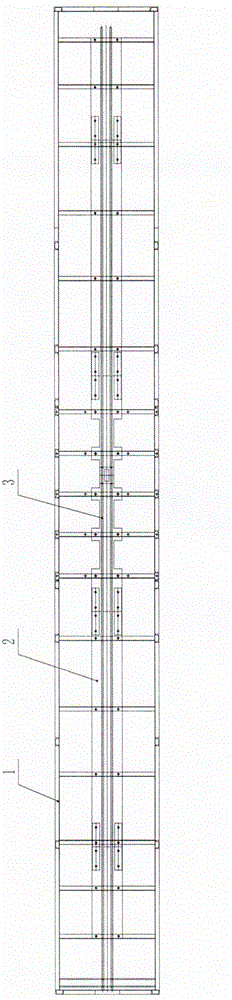

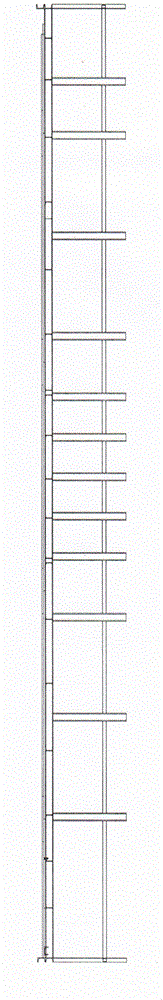

[0040] A wire drawing machine used for wire drawing treatment on the surface of automobile step bars, such as figure 1 As shown, it is composed of a workbench, tooling clamping mechanism, feed transmission mechanism, wire drawing mechanism, limit mechanism, circuit control and air circuit control, such as figure 2 and image 3 As shown, the workbench is composed of a frame 1, a work platform 2 and two transmission guide rails 3, the work platform 2 is arranged on the frame 1, and the two transmission guide rails 3 are arranged in the middle of the work platform 2 in parallel;

[0041] like Figure 4 As shown, the tooling clamping mechanism is composed of a clamping cylinder 4, an optical axis ejector rod 5, three linear bearings 6, a front clamping block 7, a plurality of lever body fixing plates 8, a T-shaped chute 9, and a plurality of T Type slider 10 and rear clamping block 11, the clamping cylinder 4 is connected with the leftmost T-shaped slider 10 through a bar body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com