Automatic overturning and transmitting device for cigarette packet

A technology of automatic inversion and transmission device, applied in packaging and other directions, can solve the problems of poor placement of cigarette packets, increased labor intensity, messy cigarette packets, etc., to achieve automatic inversion and smooth transmission, and easy installation and debugging. , easy-to-check effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

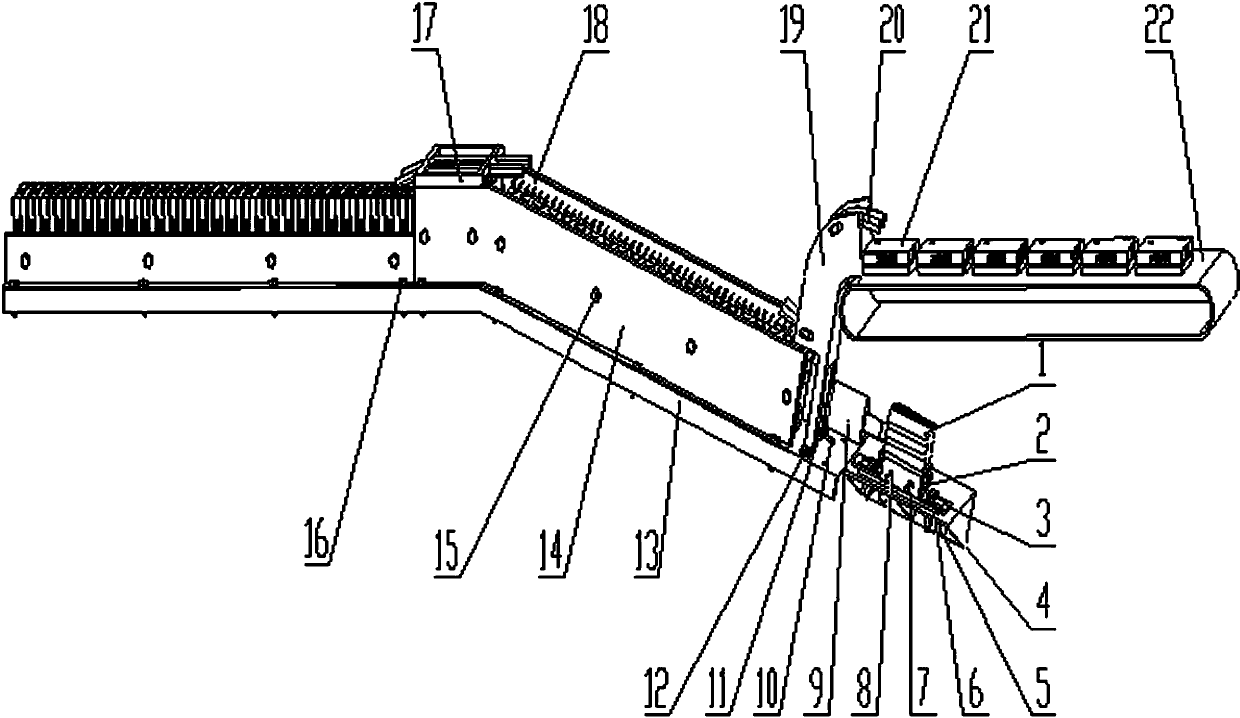

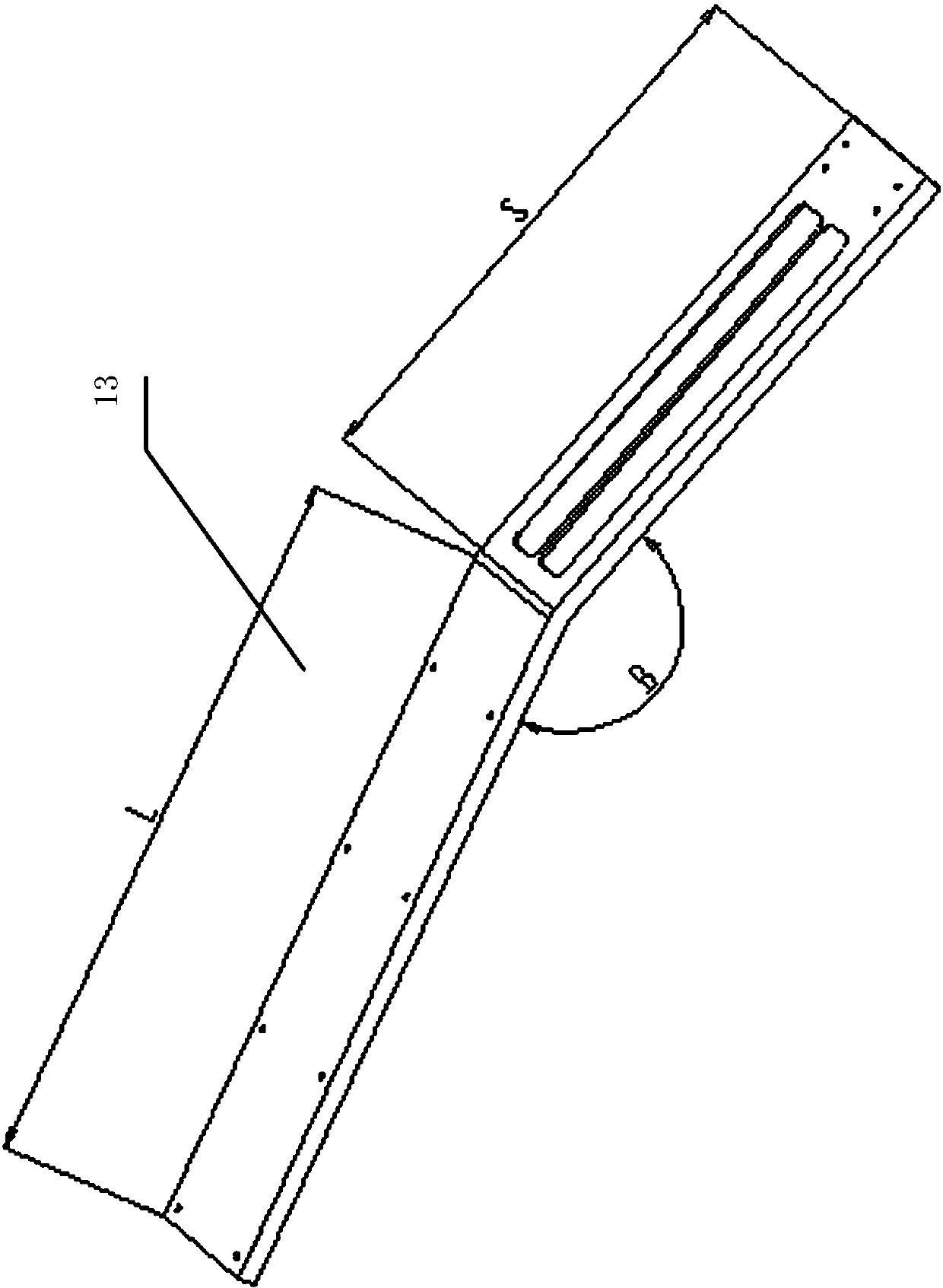

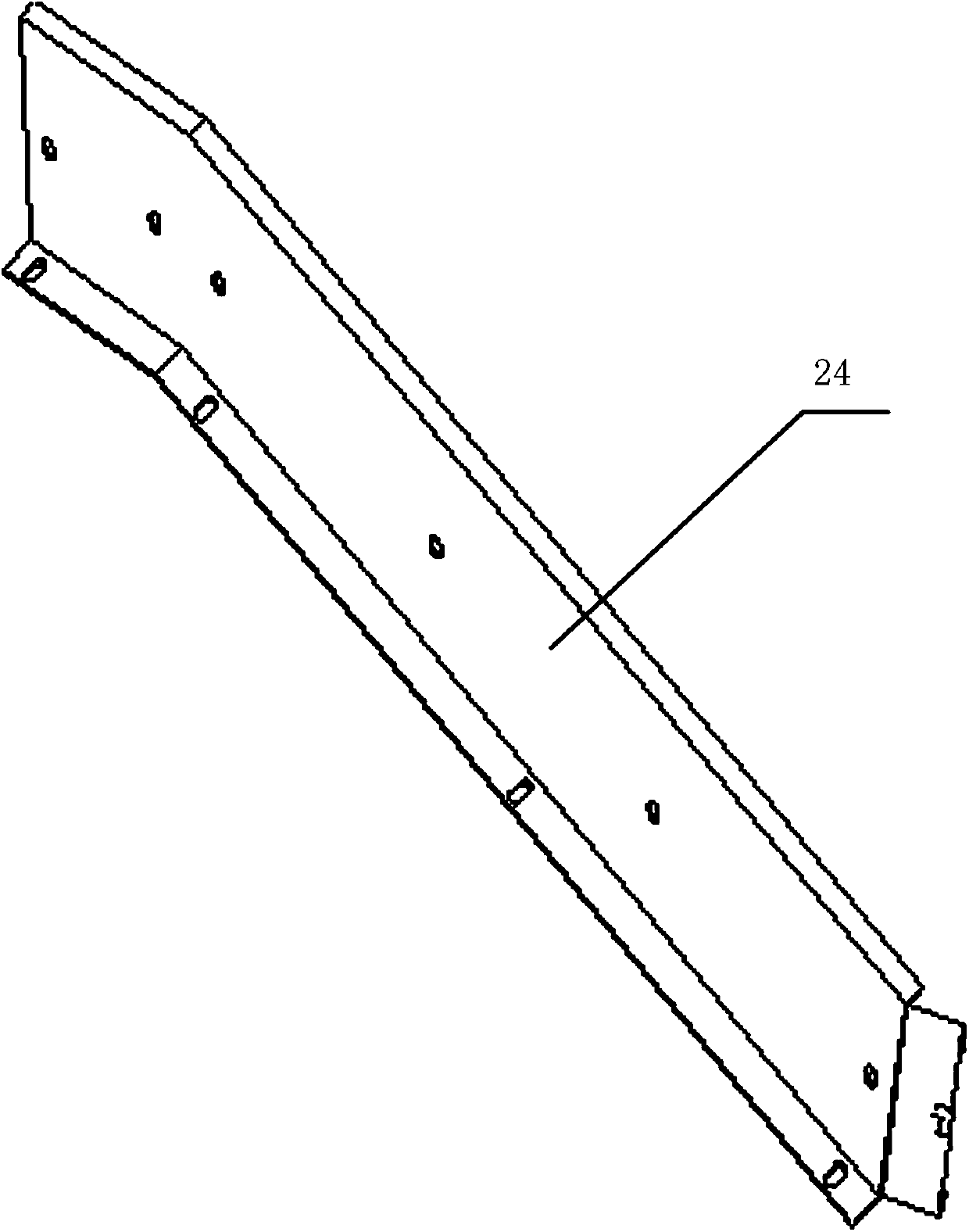

[0041] Example 1 : see figure 1 , using a stainless steel plate design base 13, consisting of two parts, such as figure 2 , the S length is designed to be 540mm, the L length is designed to be 700mm, the angle B between the L and S parts is 163°, and the holes for installing the brush holders 14, 24, 26 and slideways 19 are designed on the base 13, and the positions of the holes Corresponding to the positions of the brush holders 14, 24, 26 and the hole positions of the slideway 19, two long waist grooves are divided in the central part of the S section to reduce the friction area of the small cigarette case 21 on the oil seal surface during transmission; symmetrical design Hairbrush seat 14 and beginning end hairbrush seat 24, end hairbrush seat 26, as image 3 and Figure 4 , and design the waist hole for installing the brush and connecting the base 13, for installing the brush 18, 23, 25, the height H1 of the brush seat 14 is designed as the width value of the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com