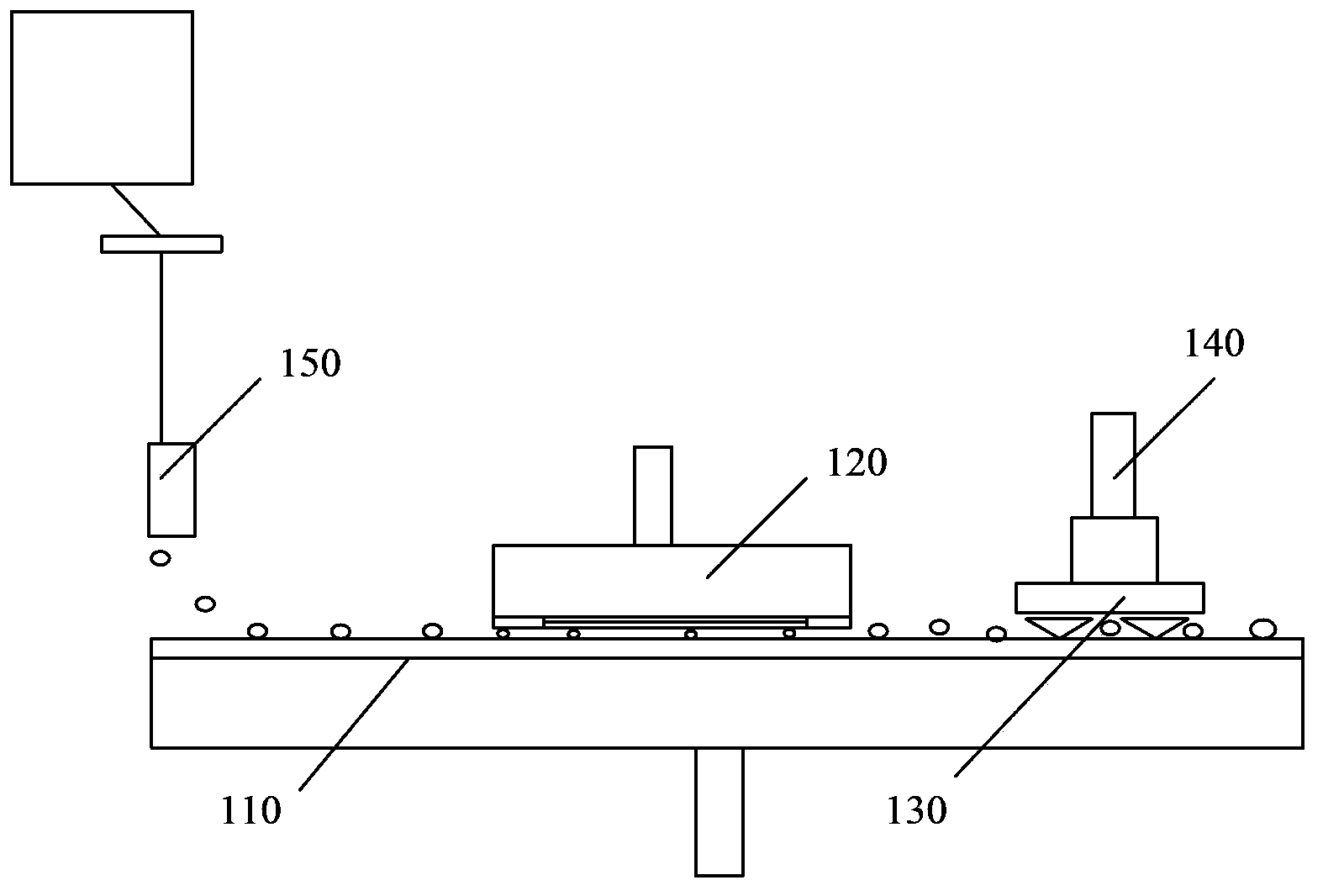

Method for arranging grinding pad, grinding pad arranging device and grinder table

A pad organizer and grinding pad technology, which is applied in the directions of grinding machine tools, grinding devices, and parts of grinding machine tools, can solve the problems of easy collision with the grinding head, reduced product yield, and easy collision with other adjacent parts, etc. Product yield, the effect of avoiding contamination of the wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

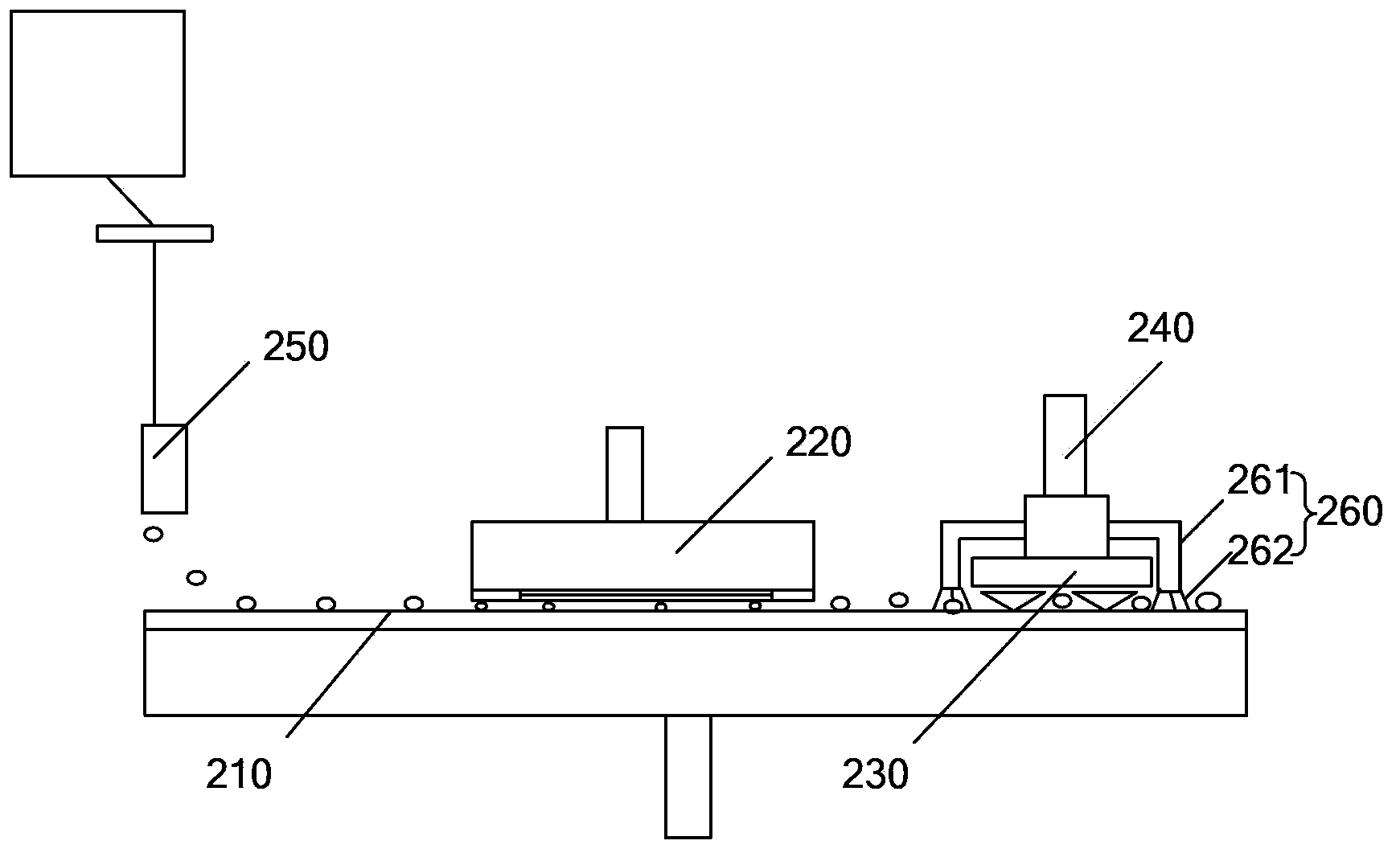

[0033] This embodiment provides a polishing pad finishing method, please refer to figure 2 and image 3 , when the wafer is ground, the grinding disc 230 presses down to arrange the grinding pad 210, and during the process from grinding one wafer to the next wafer grinding, the grinding disc 230 stays at the grinding position with zero pressure. Pad 210 on. Since the grinding disc 230 rests on the grinding pad 210 with zero pressure during the process from grinding a wafer to before starting the grinding of the next wafer, the grinding disc 230 can be used during the entire process of grinding a batch of wafers. It stays on the grinding pad 210 all the time without reciprocating movement between the cleaning area, thereby avoiding the repeated upward and downward movement of the grinding disc 230. On the one hand, it can prevent the grinding disc 230 from being damaged during the upward and downward movement The wafer, on the other hand, can also prevent the particulate mat...

Embodiment 2

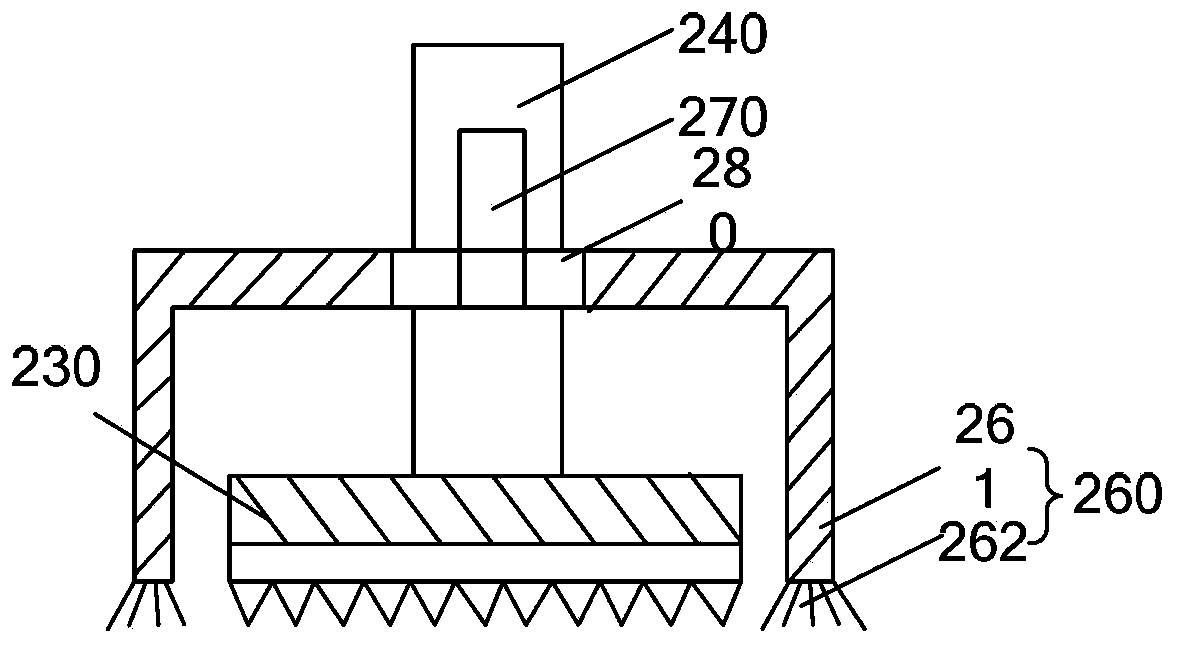

[0040] read on figure 2 and image 3 , a polishing machine platform provided in this embodiment includes a polishing pad 210 , a polishing pad finisher, a polishing head 220 and a polishing liquid supply pipeline 250 , and the polishing pad finisher is arranged on the polishing pad 210 . The grinding pad finisher includes a grinding disc 230 and a driving shaft 240 , the driving shaft 240 is fixedly connected with the grinding disc 230 , and the driving shaft 240 drives the grinding disc 230 to rotate.

[0041] Preferably, the grinder table further includes at least one pair of cleaning tools 260, an up and down driving part 270 and an opening and closing driving part 280, the up and down driving parts 270 are mounted on the drive shaft 240, and the cleaning tools 260 are The up and down driving part 270 moves up and down, and the cleaning tool 260 moves inward or outward under the driving part 280 .

[0042] The number of the cleaning tool 260 may be one, or more than two....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com