Elastic phenylethylene-ester acrylate water-proof emulsion and preparation method thereof

A technology of acrylate and waterproof emulsion, which is applied in the direction of building components, building insulation materials, etc., can solve the problem that the elongation at break and tensile strength of waterproof coatings cannot be achieved, and the tensile strength and elongation at break cannot be met at the same time, and waterproof The paint is easy to turn green and equal, and achieves the effect of good acid and alkali resistance, low cost and stable hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

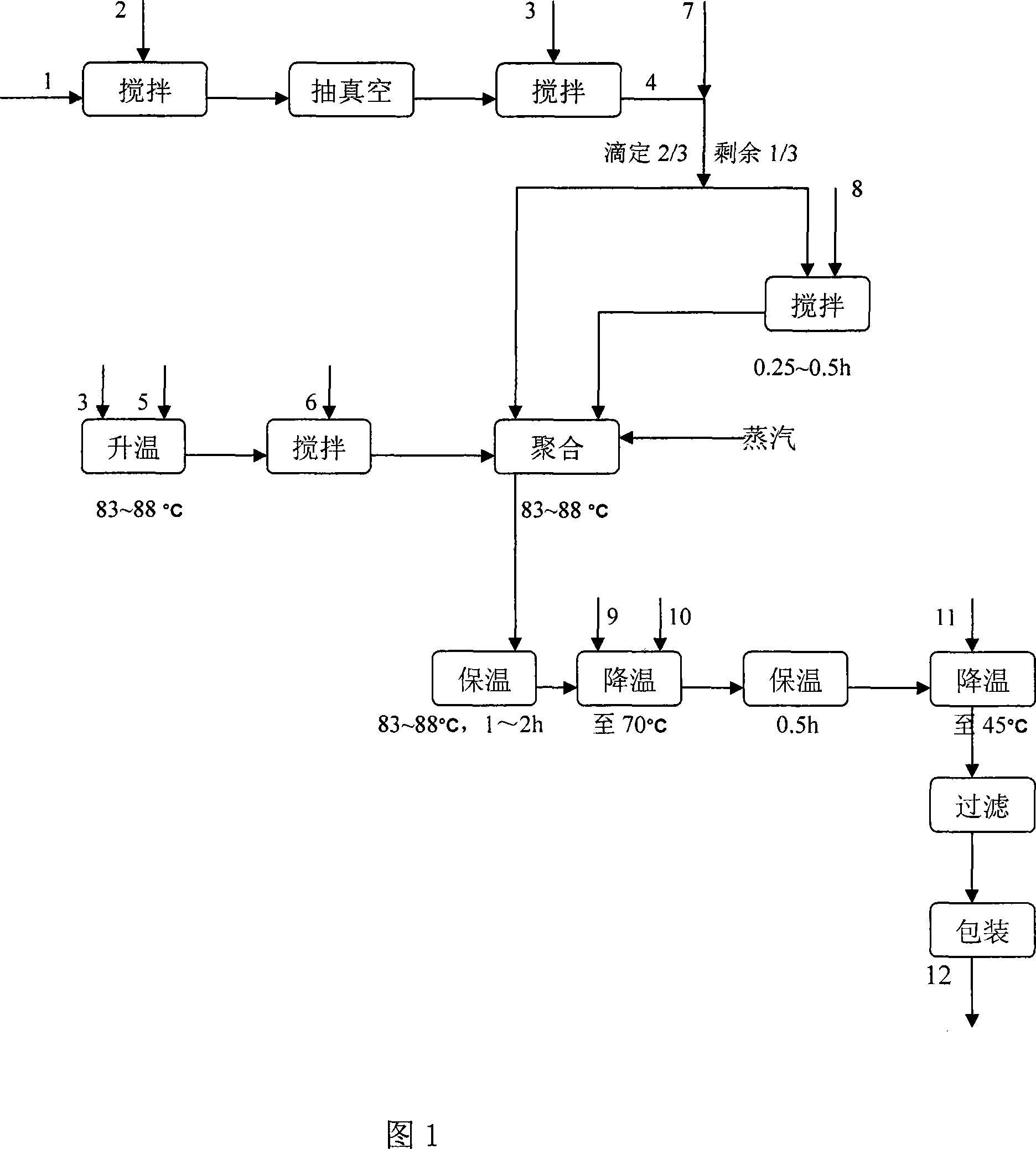

[0056] The elastic styrene-acrylate waterproof emulsion of the present invention and its preparation method will be further described in detail below in conjunction with the accompanying drawings.

[0057] The present invention is an elastic styrene-acrylate waterproof emulsion with improved performance, which is composed of a melt-polymerized mixed solution, and its composition and weight percentage are as follows:

[0058] (A) component a 1 , the dosage is 14.8~29.9%, the component a 1 is composed of:

[0059] (a) 10.5-20.0% deionized water;

[0060] (b) 0.3% to 1.0% of 2A 1 anionic emulsifier;

[0061] (c) 0.6-1.6% OP-10 polyoxyethylene alkaryl ether anionic emulsifier;

[0062] (d) 0.03% to 0.10% of A-501 anionic emulsifier;

[0063] (e) 2.0-4.8% deionized water;

[0064](f) 1.4% to 2.4% of acryloyl ammonium functional monomer;

[0065] (B) Component a 2 , the dosage is 49.0~58.0%, the component a 2 is composed of:

[0066] (a) 37.0%~42.0% n-butyl acrylate soft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com