Water-based single-component modified epoxy resin as well as preparation method and application thereof

An epoxy resin, one-component technology, applied in the field of polymers, can solve the problems of slow drying speed, high content of unsaturated fatty acids, large particle size of epoxy emulsion, etc., and achieve long service life, good adhesion and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

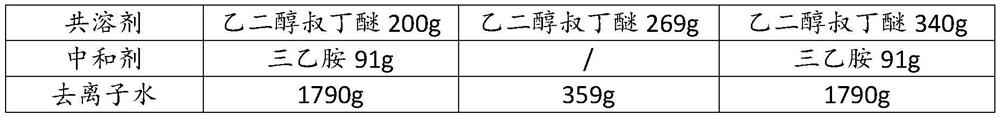

[0048] In this example, a water-based one-component modified epoxy resin is prepared, and the specific preparation process is as follows:

[0049] The E12 epoxy resin of 800g, 200g linseed oil fatty acid hemp, 72g soybean oil fatty acid, 1.1g zinc oxide catalyst are put into reaction still, be warmed up to 140 degree and react until acid value is less than 3; Add 355g ethylene glycol tert-butyl ether, 14g ring Stir the oxyphosphate ester evenly, keep the temperature at 150°C, add dropwise a mixture of 7g DTAP initiator and 280g methyl methacrylate within 3-4h, then dropwise add a mixture of 2gDTAP initiator and 65g acrylic acid within 0.5-1h, keep at 150°C for 1h , then add 1gDTAP initiator for the first time, keep warm for 1h, then add 1gDTAP initiator for the second time and keep warm for 1h, and add 1gDTAP initiator for the third time and keep warm for 2-3h. Cool down to 80°C, add 91g of triethylamine neutralizer dropwise within 30 minutes, then add 1790g of deionized water...

Embodiment 2

[0057] In this example, a water-based one-component modified epoxy resin is prepared, and the specific preparation process is as follows:

[0058] Heat 380g of E51 epoxy resin, 6g of F51 novolac epoxy resin, 4.5g of polyether sulfonate, 185g of bisphenol A, 40g of benzoic acid, 10g of coconut oil fatty acid and 6.25g of epoxy phosphate to 100°C, stir and mix evenly, Add 0.9g of boron trifluoride amine complex, react at 120°C-130°C for 2h, and take samples to measure the epoxy value;

[0059]When the theoretical value is reached, add 269g of ethylene glycol tert-butyl ether and stir evenly, lower the temperature to 60°C and slowly add 359g of deionized water dropwise, and at the same time turn the speed to 1200r / min, stir for 2 hours, and obtain a water-based single-component solution through phase transformation Modified epoxy resin dispersion.

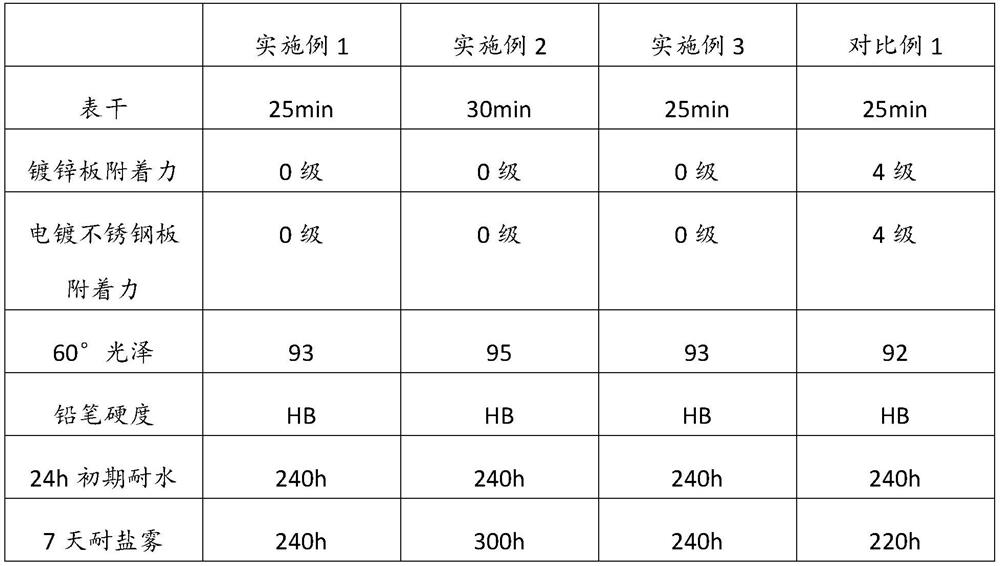

[0060] Through preliminary testing, the water-based one-component modified epoxy resin prepared by the present invention:

[0061]...

Embodiment 3

[0067] In this example, a water-based one-component modified epoxy resin is prepared, and the specific preparation process is as follows:

[0068] The E12 epoxy resin of 800g, 150g dehydrated ricinoleic acid hemp, 122g soybean oil fatty acid, 1.1g zinc oxide catalyst are dropped into reactor, be warmed up to 140 degree and react to acid value less than 3; Add 355g ethylene glycol tert-butyl ether, Stir 14g epoxy phosphate ester evenly, keep the temperature at 150°C, add 7g DTAP initiator and 280g methyl methacrylate mixture dropwise within 3-4h, then add 2g DTAP initiator and 65g acrylic acid mixture dropwise within 0.5-1h, 150°C Keep warm for 1h, then add 1gDTAP initiator for the first time, keep warm for 1h, then add 1gDTAP initiator for the second time, keep warm for 1h, and add 1gDTAP initiator for the third time, keep warm for 2-3h. Cool down to 80°C, add 91g of triethylamine neutralizer dropwise within 30 minutes, then add 1790g of deionized water dropwise within 1.5h, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com