Composition for forming cured film pattern, and method for producing cured film pattern by using the same

A technology of composition and compound, which is applied in the direction of photographic plate-making process of patterned surface, semiconductor/solid-state device manufacturing, and photosensitive material used in optomechanical equipment, etc. Achieves excellent storage stability, excellent resistance to electroless gold plating, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

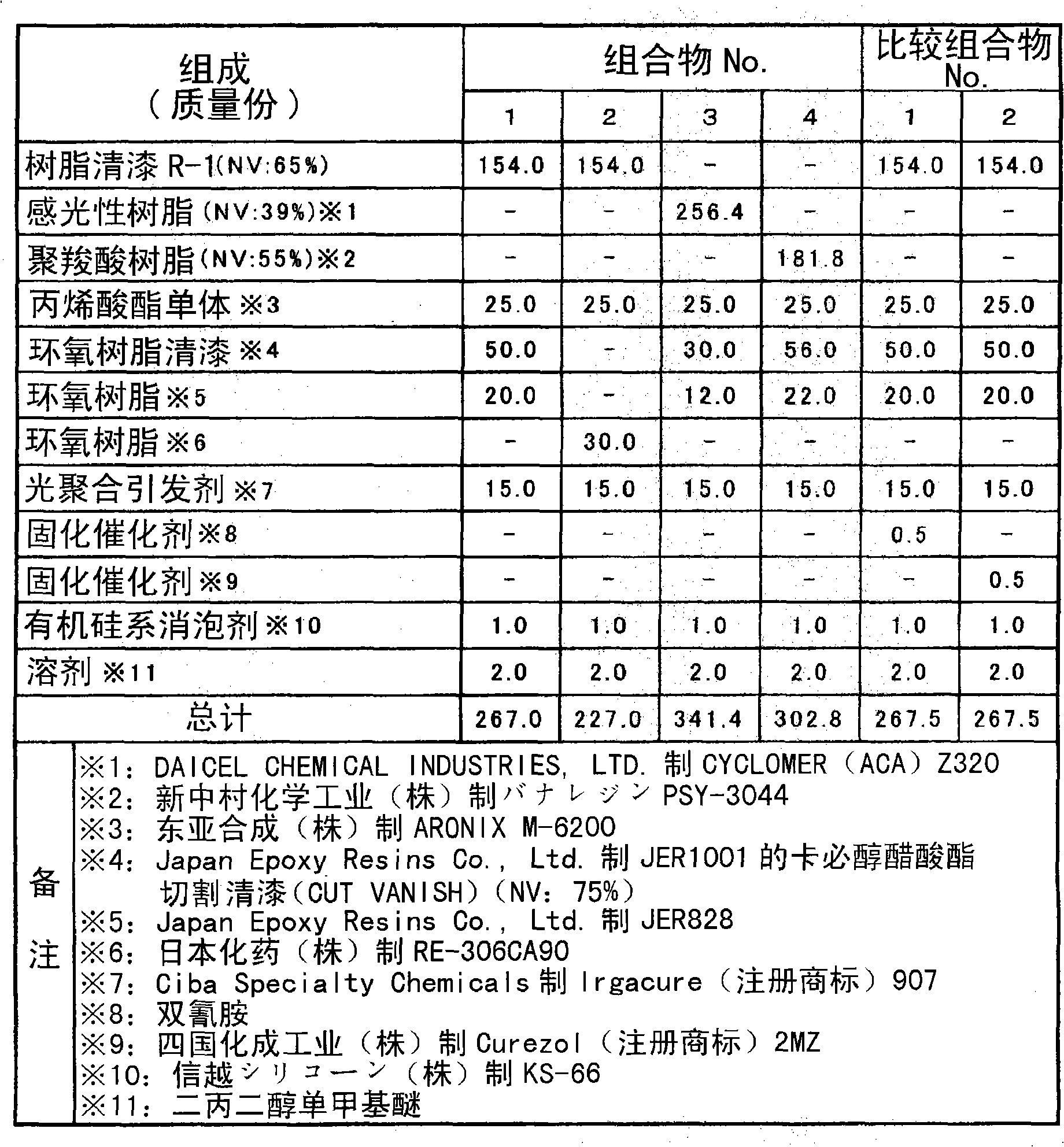

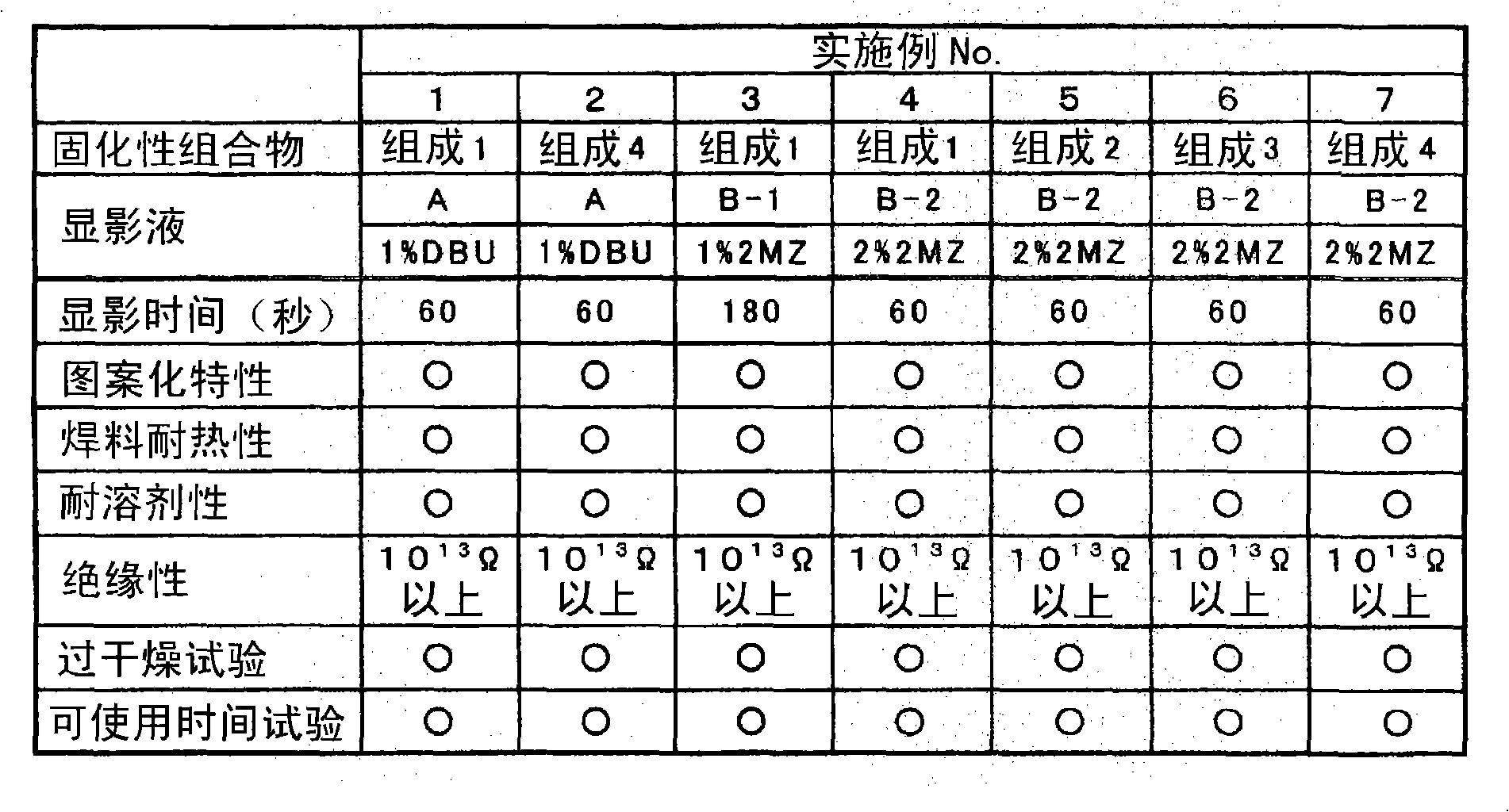

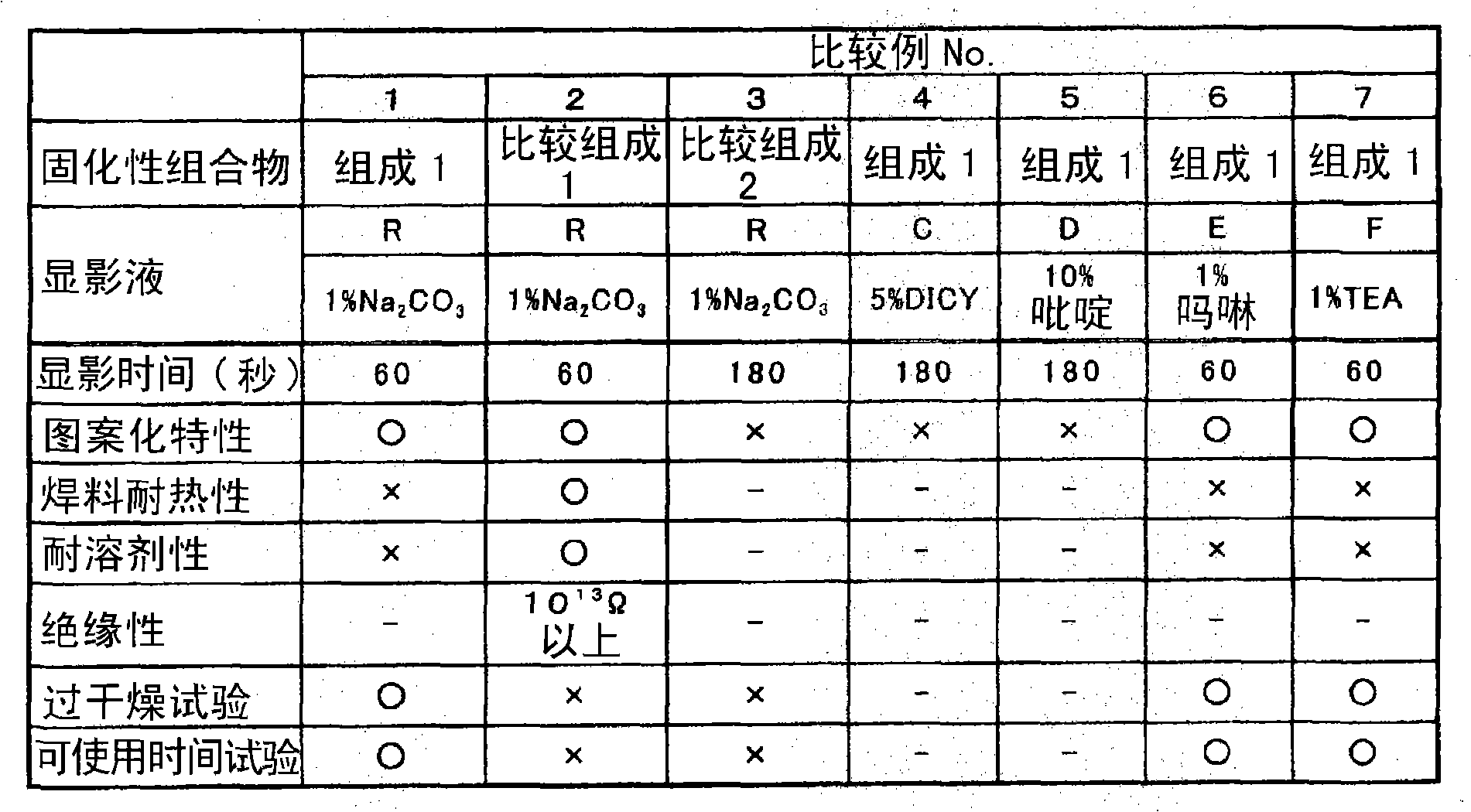

Method used

Image

Examples

Embodiment

[0067] Hereinafter, although an Example etc. are shown and this invention is demonstrated more concretely, this invention is not limited to these Examples. In addition, unless otherwise specified below, "part" means a mass part.

Synthetic example

[0069] In a flask equipped with a thermometer, a stirrer, a dropping funnel, and a reflux cooler, measure 210 parts of cresol novolak-type epoxy resin (EPICLON (registered trademark) N-680, manufactured by Dainippon Ink Chemical Industry Co., Ltd., Epoxy equivalent=210) and 96.4 parts of carbitol acetate, heated to dissolve. Next, add 0.1 part of hydroquinone as a polymerization inhibitor, and 2.0 parts of triphenylphosphine as a reaction catalyst. Heat the mixture to 95-105°C, slowly drop in 72 parts of acrylic acid until the acid value reaches below 3.0 mgKOH / g, and react for about 16 hours. Cool the reaction product to 80-90°C, add 76.1 parts of tetrahydrophthalic anhydride, and react for about 6 hours until there is no anhydride absorption peak (1780cm -1 ). 96.4 parts of aromatic solvents (manufactured by Idemitsu Petrochemical Co., Ltd., trade name IPSOL#150) were added to this reaction liquid, and it extracted after diluting. The thus obtained resin varnish having tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com