Storage battery sealing gum and preparation method of storage battery sealing gum

A sealant and storage battery technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of short usable time and unusable glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

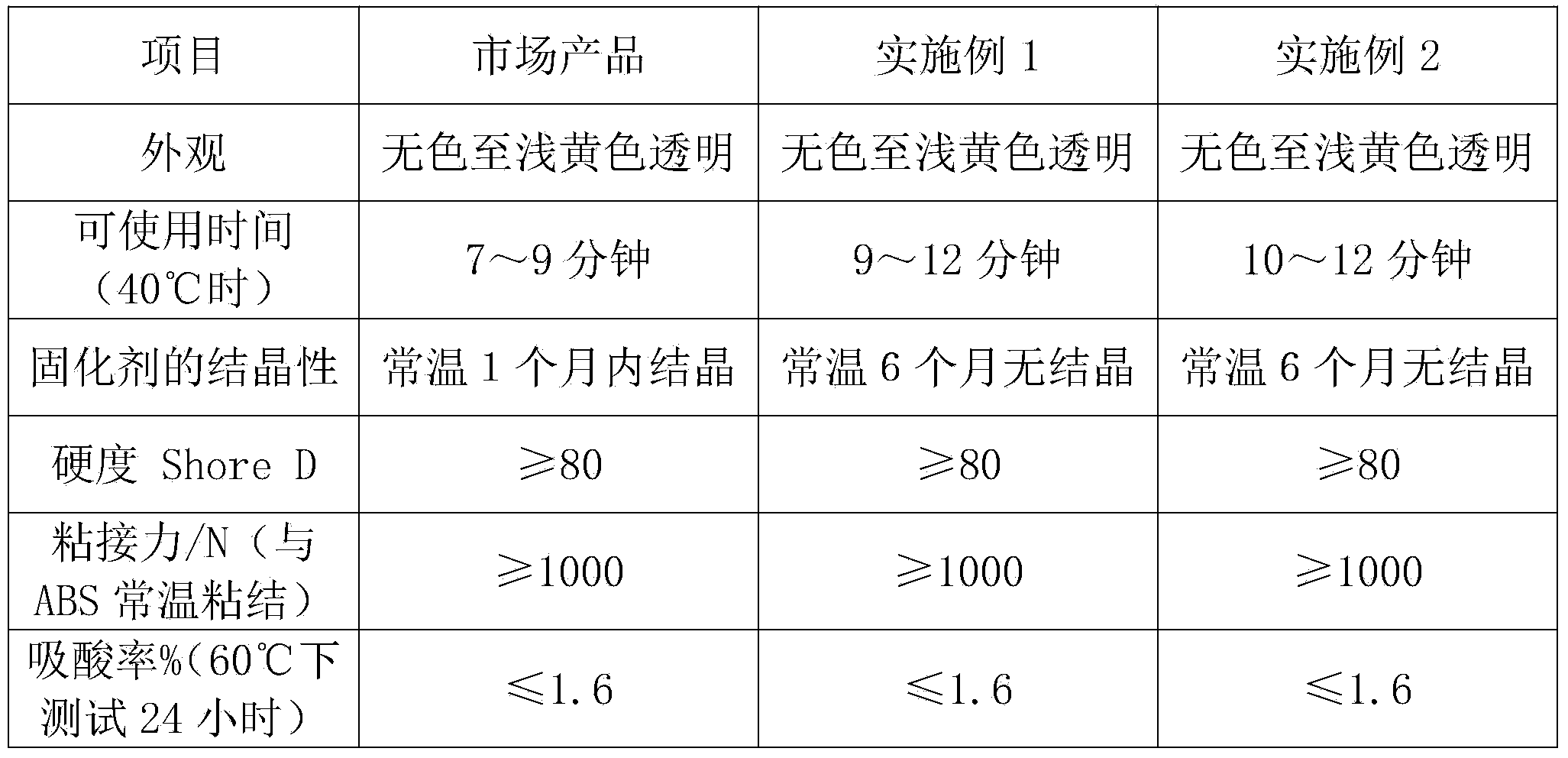

Examples

Embodiment 1

[0019] (1) Mix the raw materials described in the resin part according to the stated ratio, vacuumize, and heat up to 45°C, and stir well; (2) Mix the alicyclic amine in the curing agent part and 65% of the total Mix the amine evenly, raise the temperature to 55°C, drop in 50% active diluent of the total material while stirring, then slowly raise the temperature to 70°C, add the remaining aliphatic polyamine while stirring, drop in the remaining active diluent while stirring Diluent, finally heat up to 70°C and stir well; (3) Mix the product obtained in step (1) with step (2); the above resin part includes 90 parts of bisphenol A epoxy resin; reactive diluent 8 parts of antifoaming agent; 2 parts of antifoaming agent; The above-mentioned curing agent part comprises, 47 parts of aliphatic polyamine; 25 parts of alicyclic amine; 28 parts of reactive diluent; . In step (1), the vacuum degree is controlled at 710 mm Hg, and the temperature is controlled at 45°C. The temperature ...

Embodiment 2

[0021] (1) Mix the raw materials described in the resin part according to the stated ratio, evacuate, heat up to 57°C, and stir well; (2) Mix the alicyclic amine in the curing agent part and 76% of the total Mix the amine evenly, raise the temperature to 50°C, drop in 60% active diluent of the total material while stirring, then slowly raise the temperature to 60°C, add the remaining aliphatic polyamine while stirring, drop in the remaining active diluent while stirring Diluent, finally heat up to 75°C and stir well; (3) Mix the product obtained in step (1) with step (2); the above-mentioned resin part includes 93 parts of bisphenol A epoxy resin; reactive diluent 6 parts of antifoaming agent; 1 part of defoaming agent; the above-mentioned curing agent part includes, 42 parts of aliphatic polyamine; 22 parts of alicyclic amine; 36 parts of reactive diluent; . In step (1), the vacuum degree is controlled at 750 mm Hg, and the temperature is controlled at 50° C. The temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com