Hydroxyl acrylic resin aqueous dispersion and preparation method thereof

A technology of hydroxyacrylic acid and dispersion, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of low foam-free film thickness, side reactions of curing agents, high overall cost of coatings, etc., to improve the foam-free film thickness, Good bubble-free film thickness and good emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of aqueous dispersion of hydroxyacrylic resin compatible with solvent type isocyanate curing agent of the present invention and a kind of embodiment of preparation method thereof, specifically as follows:

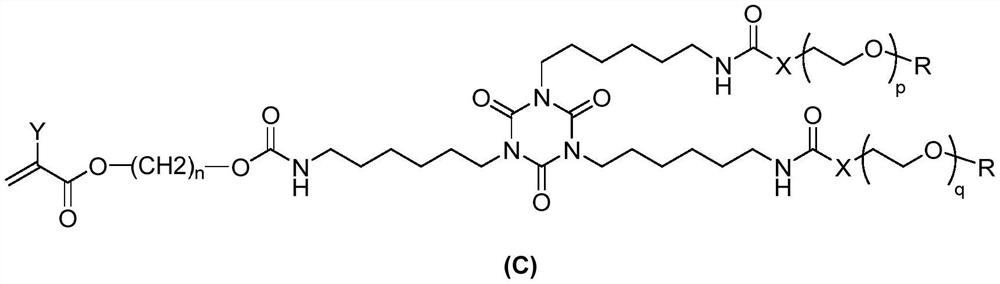

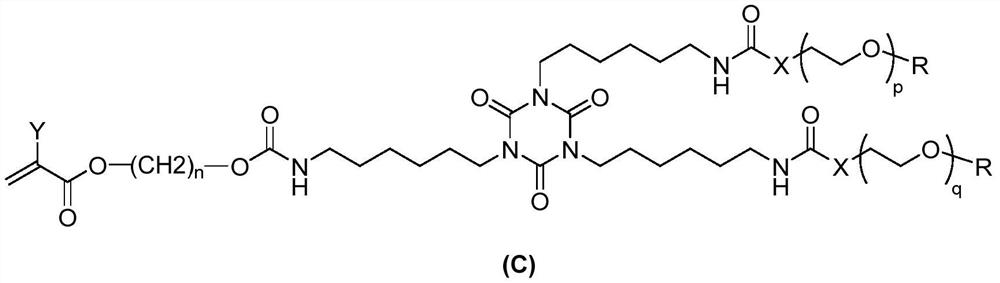

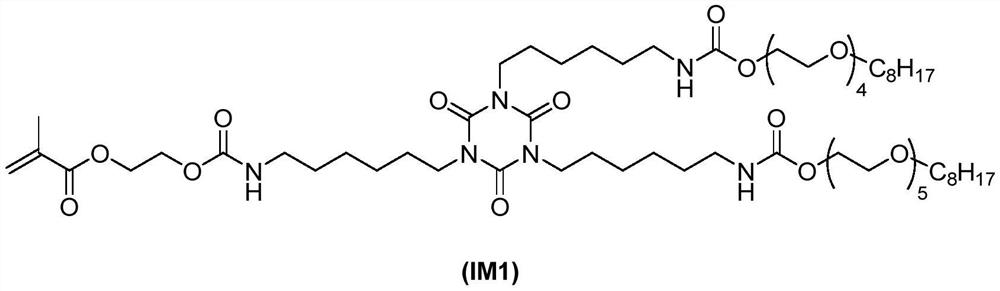

[0030] (1) Synthesis of unsaturated monomer IM1 containing HDI trimer structure

[0031] Add 100.0g Desmodur N 3300 (Covestro HDI trimer, NCO value 21.8%), 0.16g BHT, 0.16g bismuth isooctanoate into the reaction vessel, raise the temperature to 90°C, slowly add 19.3g methacrylic acid hydroxy Ethyl ester was dripped into the reaction vessel, and the dripping was completed in about 30 minutes, and then kept at 90° C. for 3 hours. Slowly add 113.4g of Dehydrol O4 (Corning non-ionic surfactant, adduct of 1mol octanol and 4mol ethoxy) in about 30 minutes, then keep warm at 90°C until the NCO value is zero. The obtained clear transparent liquid is the unsaturated monomer IM1 containing HDI trimer structure, and its approximate structure is as follows, which conform...

Embodiment 2

[0037] A kind of aqueous dispersion of hydroxyacrylic resin compatible with solvent type isocyanate curing agent of the present invention and a kind of embodiment of preparation method thereof, specifically as follows:

[0038] (1) Synthesis of unsaturated monomer IM1 containing HDI trimer structure

[0039] Add 100.0g Desmodur N 3300 (Covestro HDI trimer, NCO value 21.8%), 0.16g BHT, 0.16g bismuth isooctanoate into the reaction vessel, raise the temperature to 90°C, slowly add 19.3g methacrylic acid hydroxy Ethyl ester was dripped into the reaction vessel, and the dripping was completed in about 30 minutes, and then kept at 90° C. for 3 hours. Slowly add 113.4g of Dehydrol O4 (Corning non-ionic surfactant, adduct of 1mol octanol and 4mol ethoxy) in about 30 minutes, then keep warm at 90°C until the NCO value is zero. The obtained clear transparent liquid is the unsaturated monomer IM1 containing HDI trimer structure, and its approximate structure is as follows, which conform...

Embodiment 3

[0045] A kind of aqueous dispersion of hydroxyacrylic resin compatible with solvent type isocyanate curing agent of the present invention and a kind of embodiment of preparation method thereof, specifically as follows:

[0046] (1) Synthesis of unsaturated monomer IM2 containing HDI trimer structure

[0047] Add 100.0g Desmodur N 3300 (Covestro HDI trimer, NCO value 21.8%), 0.16g BHT, 0.16g bismuth isooctanoate into the reaction vessel, raise the temperature to 90°C, slowly add 21.4g acrylate-4- The hydroxybutyl ester was dropped into the reaction vessel, and the drop was completed in about 30 minutes, and then kept at 90° C. for 3 hours. Slowly add 172.0g Lutensol TO-6 (BASF non-ionic surfactant, adduct of 1 mol isomeric tridecanyl alcohol and 6 mol ethoxy) for about 30 minutes, then keep warm at 90°C until the NCO value is zero. The obtained clear transparent liquid is the unsaturated monomer IM1 containing HDI trimer structure, and its approximate structure is as follows,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com