Method for preparing polyurethanes forming composition, polyatomic alcohol composition, and polyurethane resin

A technology of composition and polyurethane, which is applied in the field of polyurethane resin, can solve problems such as inability to use, and achieve the effect of improving operability and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0049] (1) Prepare the mixed composition

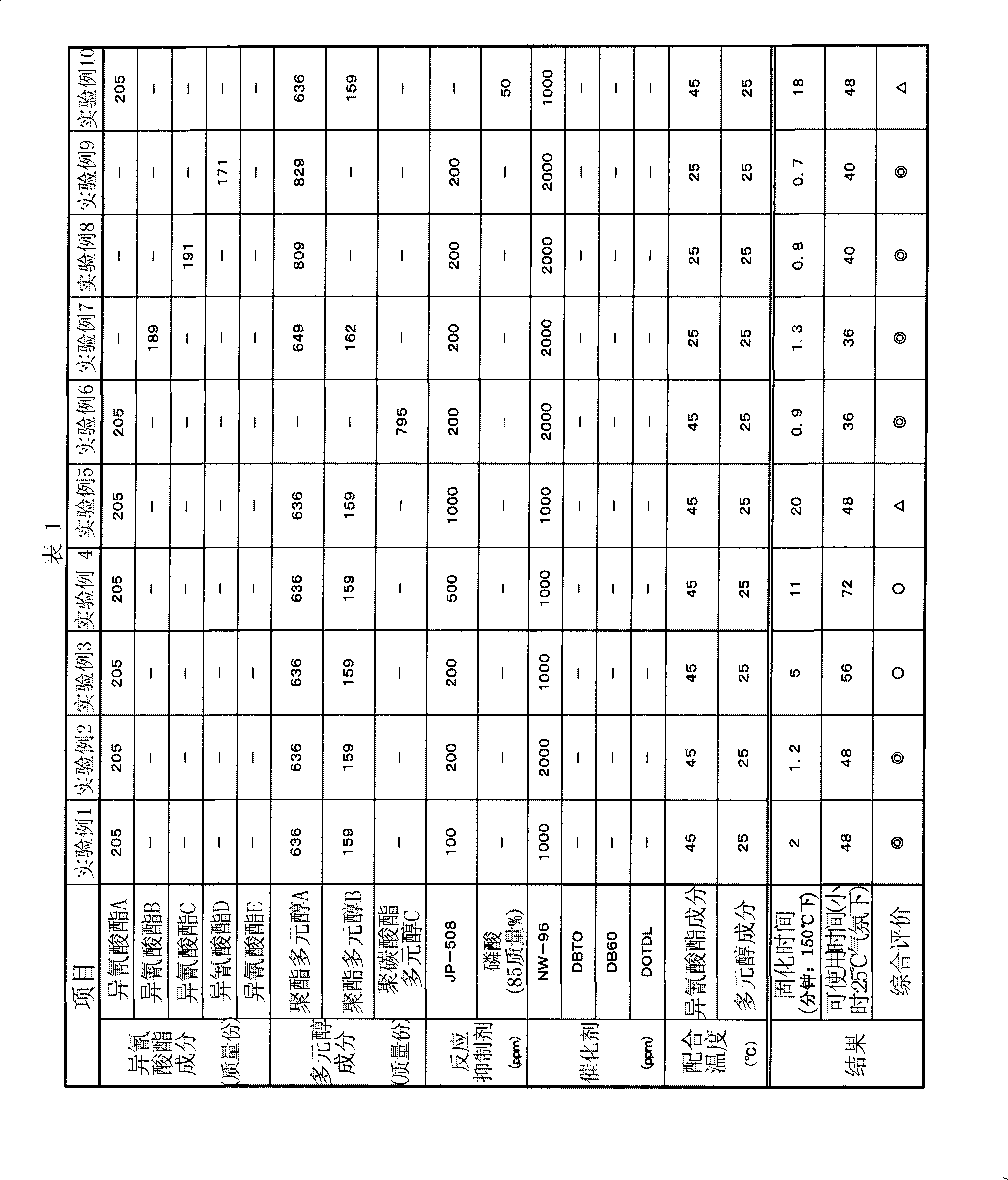

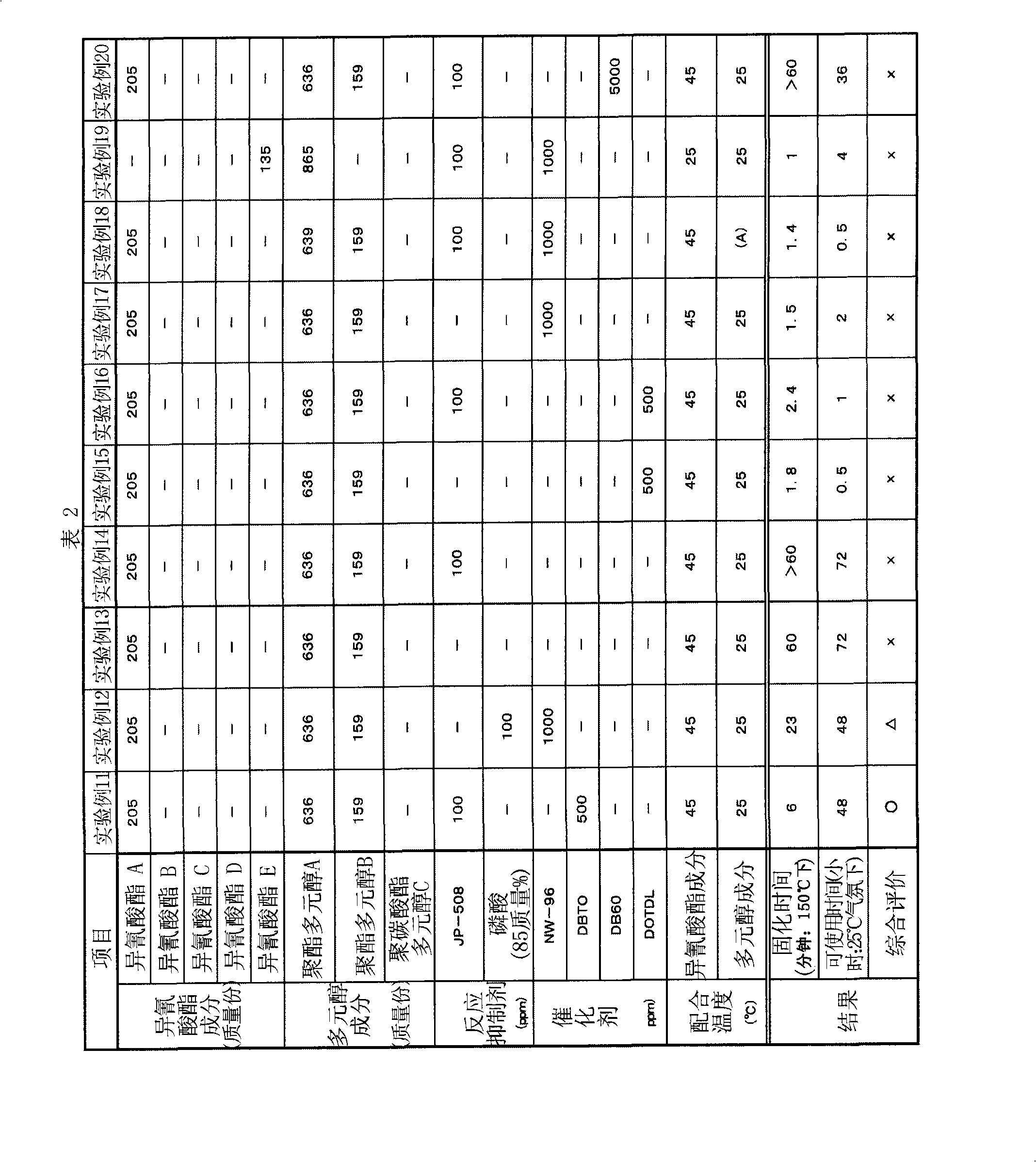

[0050] Mix 636 mass parts to obtain by 3-methyl-1,5-pentanediol (MPD) and adipic acid, number average molecular weight 2000, the normal temperature liquid polyester polyol (table 1 and 2) of nominal average functional group number Be referred to as polyester polyol A in table 2, hereinafter, be referred to as polyol A for short.), 159 mass parts are made of trimethylolpropane (TMP), 3-methyl-1,5-pentanediol (MPD) and Adipic acid obtained, number average molecular weight 3000, nominal average functional group number is 3 normal temperature liquid polyester polyols (referred to as polyester polyol B in Table 1 and Table 2, hereinafter referred to as polyol B.), JP-508 (acid phosphate: a mixture of mono(2-ethylhexyl acid phosphate) and bis(2-ethylhexyl acid phosphate) as a reaction inhibitor with respect to the polyol component 100ppm: Seonghok Kagaku Kogyo Co., Ltd.) and NW-96 of 1000 ppm relative to the polyol component to obtain a pr...

experiment example 2

[0060] (1) mixed composition modulation

[0061] A premix mixture composition having the same composition as in Experimental Example 1 was obtained except that JP-508 as a reaction inhibitor was used at 200 ppm and NW-96 as an organotin compound catalyst was used at 2000 ppm. In the same manner as in Experimental Example 1, 205 parts by mass of isocyanate A was mixed with the entire amount of the above-mentioned premix composition to obtain a polyurethane-forming mixed composition.

[0062] (2) Determination of usable time

[0063] In the same procedure as in Experimental Example 1, 50 g of the obtained polyurethane-forming mixed composition was put into a 100 ml glass bottle, and the time until the loss of fluidity was visually confirmed at a temperature of 25° C. was 48 hours.

[0064] (3) Determination of curing time

[0065] The time required for the amplitude to decrease from 9000 in the liquid state to 2000 in the rubber state was determined in the same procedure as in...

experiment example 3~5

[0069] (1) Prepare the mixed composition

[0070] A premix mixture composition having the same composition as in Experimental Example 1 was obtained except that JP-508 as a reaction inhibitor was 200 ppm (Experimental Example 3), 500 ppm (Experimental Example 4) or 1000 ppm (Experimental Example 5). In the same manner as in Experimental Example 1, 205 parts by mass of isocyanate A was mixed with the entire amount of each of the premix compositions described above to obtain a polyurethane-forming mixed composition based on each Experimental Example.

[0071] (2) Determination of usable time

[0072] According to the same procedure as in Experimental Example 1, 50 g of the polyurethane-forming mixed compositions of each Experimental Example were put into 100 ml glass bottles, and at a temperature of 25° C., timed until the fluidity disappeared visually, and the results were respectively It was 56 hours (experiment example 3), 72 hours (experiment example 4), and 48 hours (exper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com