Full-automatic kitchen waste recycling equipment and method

A technology for kitchen waste and resource regeneration, applied in the removal of solid waste and other directions, can solve the problems of secondary pollution and pipeline blockage, and achieve the effect of improving acceptance, delaying the reduction of pipe diameter, and reducing the frequency of manual cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in detail below through the embodiments and in conjunction with the accompanying drawings.

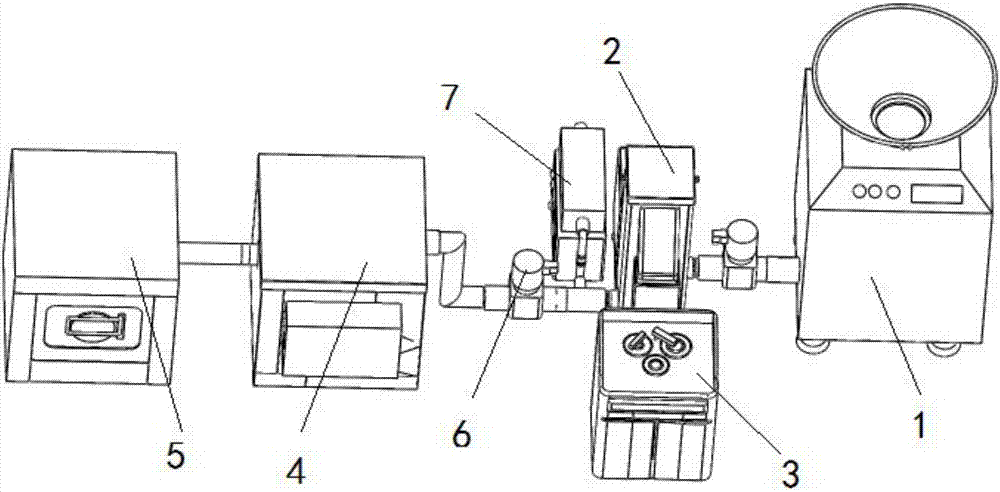

[0018] Such as figure 1 As shown, the fully automatic kitchen waste resource regeneration equipment of the present invention includes a grinding host 1, a solid-liquid separator 2, a biochemical treatment bin 3, an oil-water separator 4, and a fully automatic soap powder machine 5, wherein the grinding host 1 can The kitchen waste is crushed into granular waste, the solid-liquid separator 2 can separate the waste from solid and liquid, the biochemical treatment bin 3 can directly process the waste into biological feed or biological fertilizer, and the oil-water separator 4 can separate the solid-liquid separator 2 The liquid is separated into waste water and waste oil again, and the automatic soap powder machine 5 can reprocess the waste oil to form soap powder. Through the pipeline connection, the biochemical tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com