High efficient slow coagulating retarder for concrete and cement

A technology of concrete and reinforcing agent, which is applied in the field of concrete admixtures and cement retarders for construction. It can solve the problems that it is not suitable for ordinary cement production needs, and there are not many researches on new cement retarders, so as to achieve huge economic and social benefits. , The effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

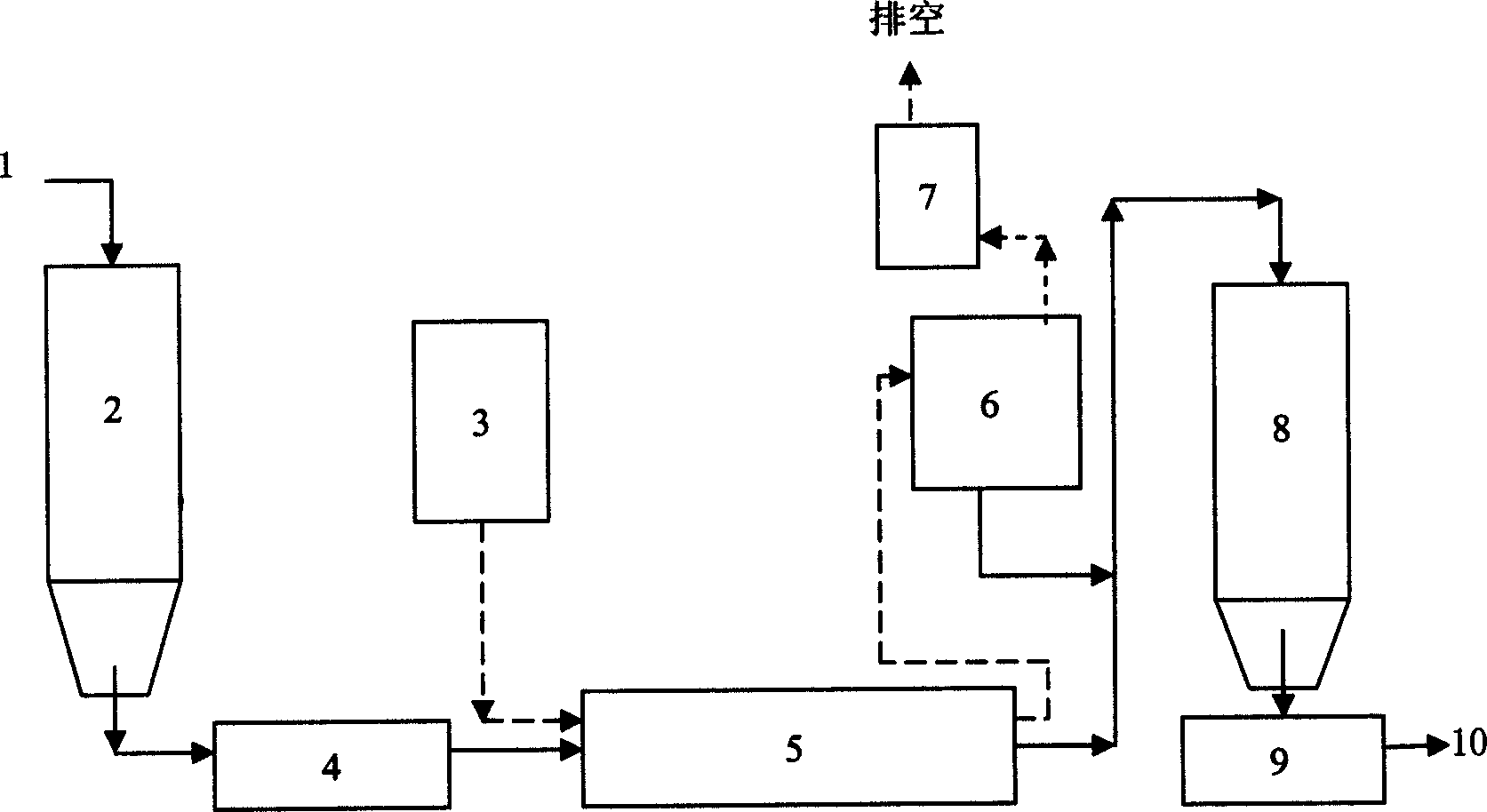

Image

Examples

example 1

[0028] Example 1: φ1.5 drum dryer, the added amount of desulfurization ash is 3.5t, and the air volume of the fan is 7000m 3 / h, the temperature of the modification chamber is 140℃, and the specific surface area of the retarder enhancer is 1000m 2 / kg around, CaSO 4 ·2H 2 The O content is about 3.5%, the crystal is fibrous, the long diameter is about 1000 nm, and the short diameter is about 100 nm.

example 2

[0029] Example 2: φ1.5 drum dryer, adding amount of desulfurization ash is 4.0t, and air volume is 9000m 3 / h, the temperature of the modification chamber is 140℃, and the specific surface area of the retarder enhancer is 830m 2 / kg around, CaSO 4 ·2H 2The O content is about 2.5%, the crystal is fibrous, the long diameter is about 1000 nm, and the short diameter is about 100 nm.

example 3

[0030] Example 3: φ1.5 drum dryer, the desulfurization ash adding amount is 5.0t, and the air volume is 9000m 3 / h, the temperature of the modification chamber is 140℃, and the specific surface area of the retarder enhancer is 900m 2 / kg around, CaSO 4 ·2H 2 The O content is about 4.0%, the crystal is fibrous, the long diameter is about 1000 nm, and the short diameter is about 100 nm.

[0031] The specific method of invented product application:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com