Production method of gypsum relief product

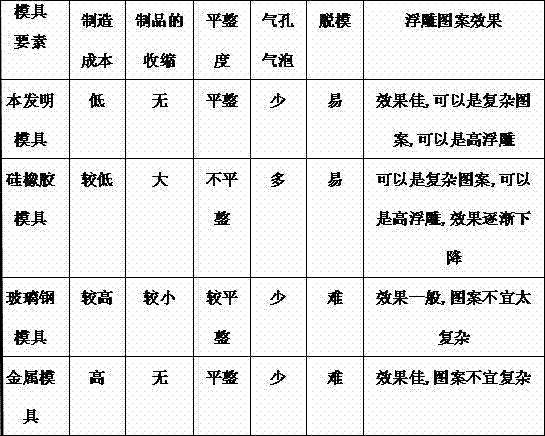

A production method and embossing technology, applied in the field of ornaments, can solve the problems of high product shrinkage, high manufacturing cost, difficult demoulding, etc., and achieve the effects of reducing the cost of molding, prolonging the initial setting time, and enhancing the surface strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Slurry preparation

[0046] ① Material preparation: high-strength gypsum powder a, redispersible latex powder b, peach gum c, sodium tetraborate d, chopped fiber e, water f,

[0047] ② Preparation method: according to the weight ratio f: b: c: d: e = 1000: 50: 5: 3: 20, various substances are prepared into a mixed emulsion g, and then a and g are prepared according to a weight ratio of 1:1 into slurry h,

[0048] (2) Mold manufacturing

[0049] A. Making the embossed master mold j: Carve the male mold with density board according to the needs, polish and repair the male mold and paint it carefully with Pu paint. After the paint film is dry, use slurry h to make the master mold. After removing the male mold, carefully repair it The master mold, after drying, finely coat it with Pu paint 3 times, polish it smooth, and then wax it once. Be careful not to fill up the small concave parts. After drying in the shade, it will be the relief master mold.

[0050] B. Making...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com