Super-retarding concrete and preparation method thereof

A concrete and super retarded technology, applied in the field of super retarded concrete and its preparation, can solve the problems of high price and high cost, and achieve the effects of low cost, enhanced fluidity and accelerated solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0042] This preparation example provides a setting retarder for concrete, which can control the concrete not to perform initial setting within 48 hours, thereby prolonging the setting time of the concrete to facilitate transportation; specifically, the setting retarder is composed of sodium citrate, sodium gluconate, Phosphogypsum, fly ash and carbide slag are compounded according to a certain weight ratio. The specific weight fraction of each component of the retarder is shown in Table 1 (1 weight fraction = 1 kg).

[0043] In the present embodiment, the preparation method of retarder is as follows:

[0044] First mix sodium citrate and sodium gluconate at room temperature (such as 20 to 40°C, preferably 30°C), then let the mixture of sodium citrate and sodium gluconate stand for at least 3 minutes, and then add phosphogypsum in turn , then the mixture of sodium citrate, sodium gluconate and phosphogypsum is stirred and fully stirred, and then fly ash and calcium carbide slag...

preparation example 2~6

[0046] Compared with Preparation Example 1, the composition of sodium citrate, sodium gluconate, phosphogypsum, fly ash and calcium carbide slag in the retarder is different, and the detailed weight ratio values of each component of the retarder are shown in Table 1 (1 weight ratio). number of servings = 1kg).

[0047]

Embodiment 1

[0049] This embodiment discloses an ultra-retarding concrete, including gel material, artificial sand, crushed stone, water reducer, retarder, and water, wherein the gel material is mixed with cement, mineral powder and coal ash. In the gel material, the weight of each of the mineral powder and coal ash in the gel material accounts for not less than 10% by weight of the gel material, and the sum of the total weight of the mineral powder and coal ash in the gel material accounts for the weight percentage of the gel material. is 20-50%, the retarder is selected from the retarder recorded in Preparation Example 1, and the specific parts by weight of each component of the concrete (1 part by weight=1kg) are detailed in Table 2;

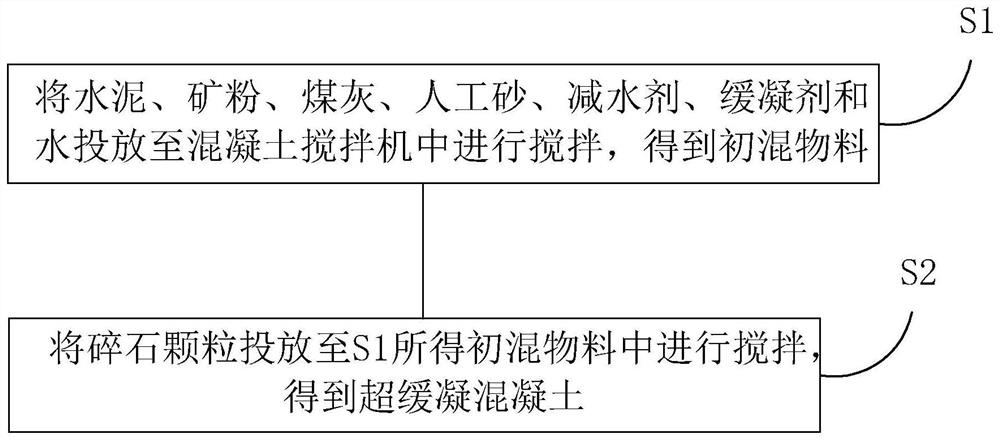

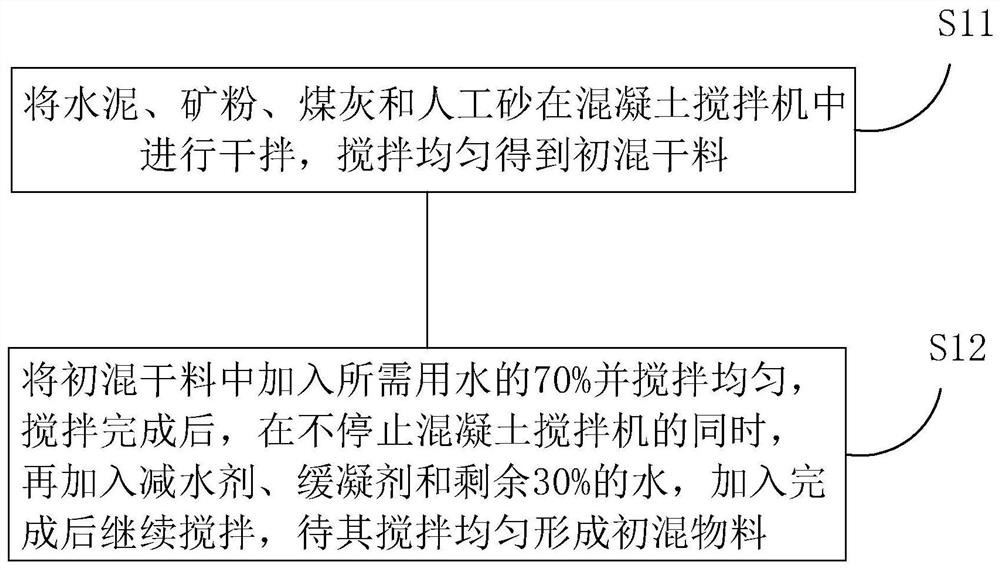

[0050] At this time, the method for preparing the concrete of the present embodiment comprises the following steps:

[0051] S1: put cement, mineral powder, coal ash, artificial sand, water reducing agent, retarder and water into a concrete mixer for mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com