Liquid container and liquid ejection system

A liquid storage container and liquid technology, applied in printing and other directions, can solve problems such as ink leakage, air introduction into ink tanks, and reduced air permeability of sheet parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0053] B-1-1. Structure of Liquid Injection System:

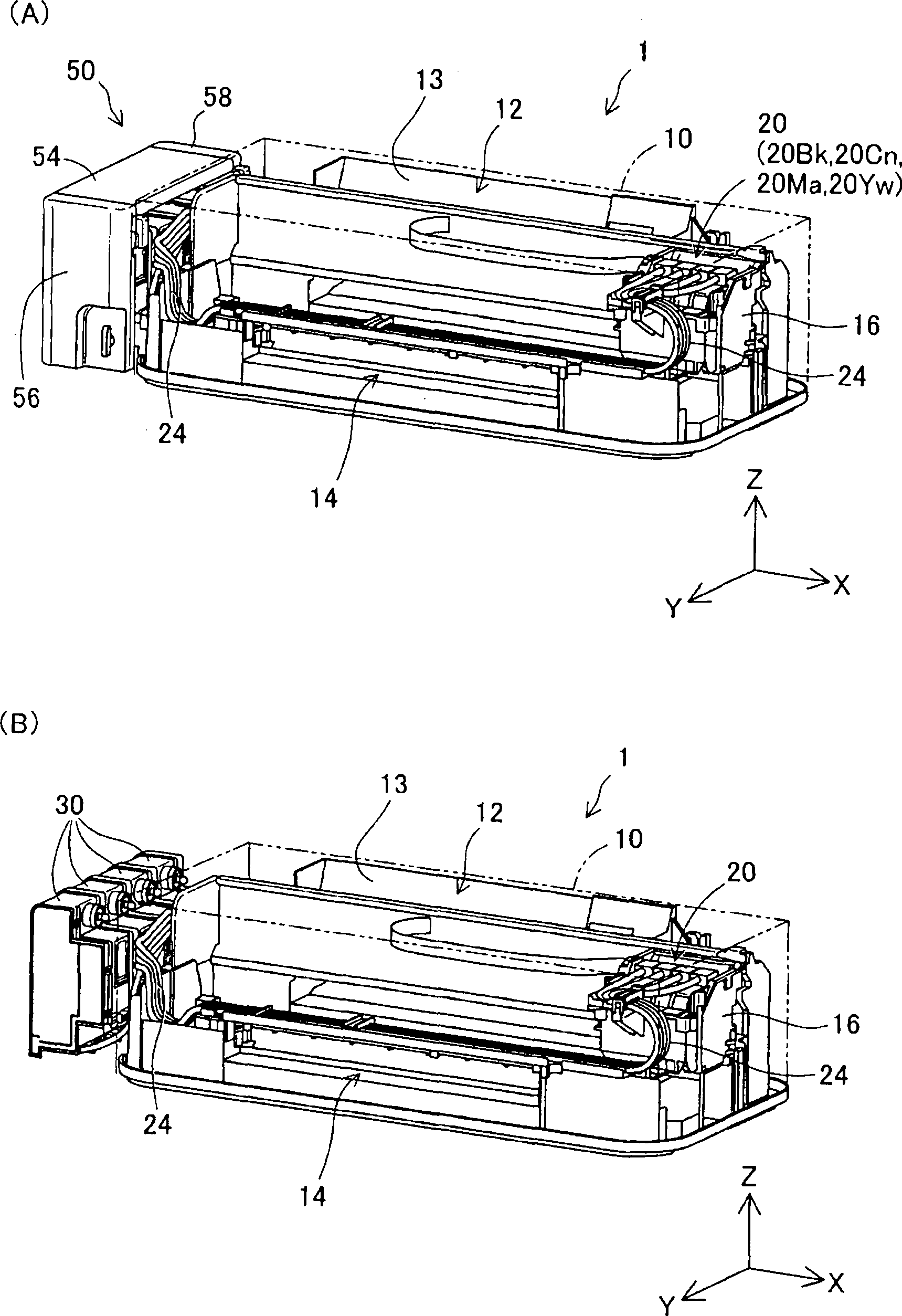

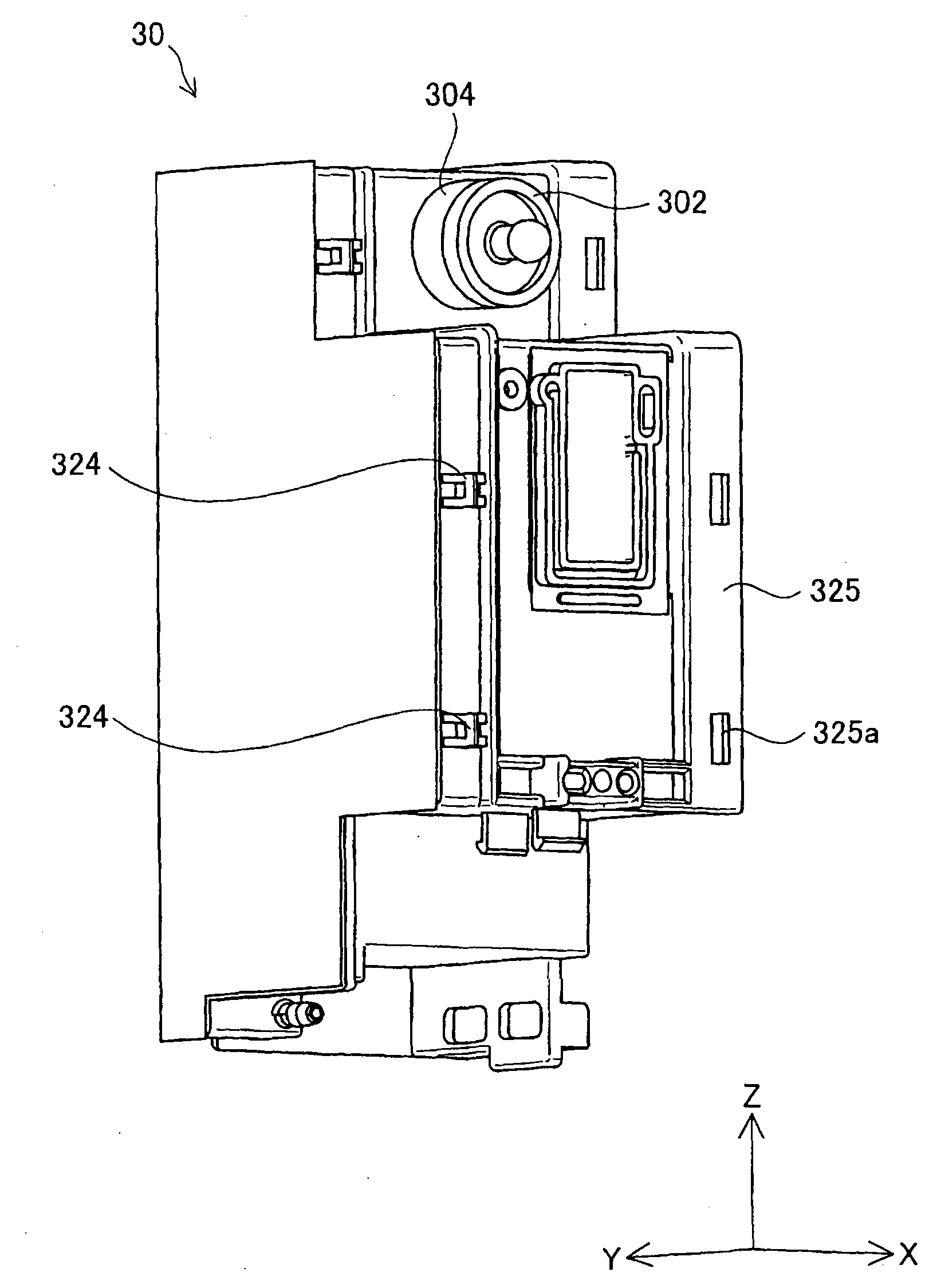

[0054] figure 2 It is a diagram for explaining the liquid ejection system 1 of the first embodiment. figure 2 (A) is an external perspective view of the liquid ejection system 1 . figure 2 (B) is an external perspective view of the liquid ejection system 1, showing the liquid storage container 30 of the first embodiment of the present invention.

[0055] Such as figure 2 As shown in (A), the liquid ejection system 1 includes an inkjet printer 12 (abbreviated as “printer 12 ”) as a liquid ejection device, and a tank unit 50 . The printer 12 includes a paper feed unit 13 , a paper discharge unit 14 , a carriage 16 and four sub tanks 20 . The four sub-tanks 20 store inks of different colors. Specifically, the four sub-tanks 20 are a sub-tank 20Bk for storing black ink, a sub-tank 20Cn for storing cyan ink, a sub-tank 20Ma for storing magenta ink, and a sub-tank 20Yw for storing yellow ink. Four sub-tanks 20 are mount...

no. 2 example

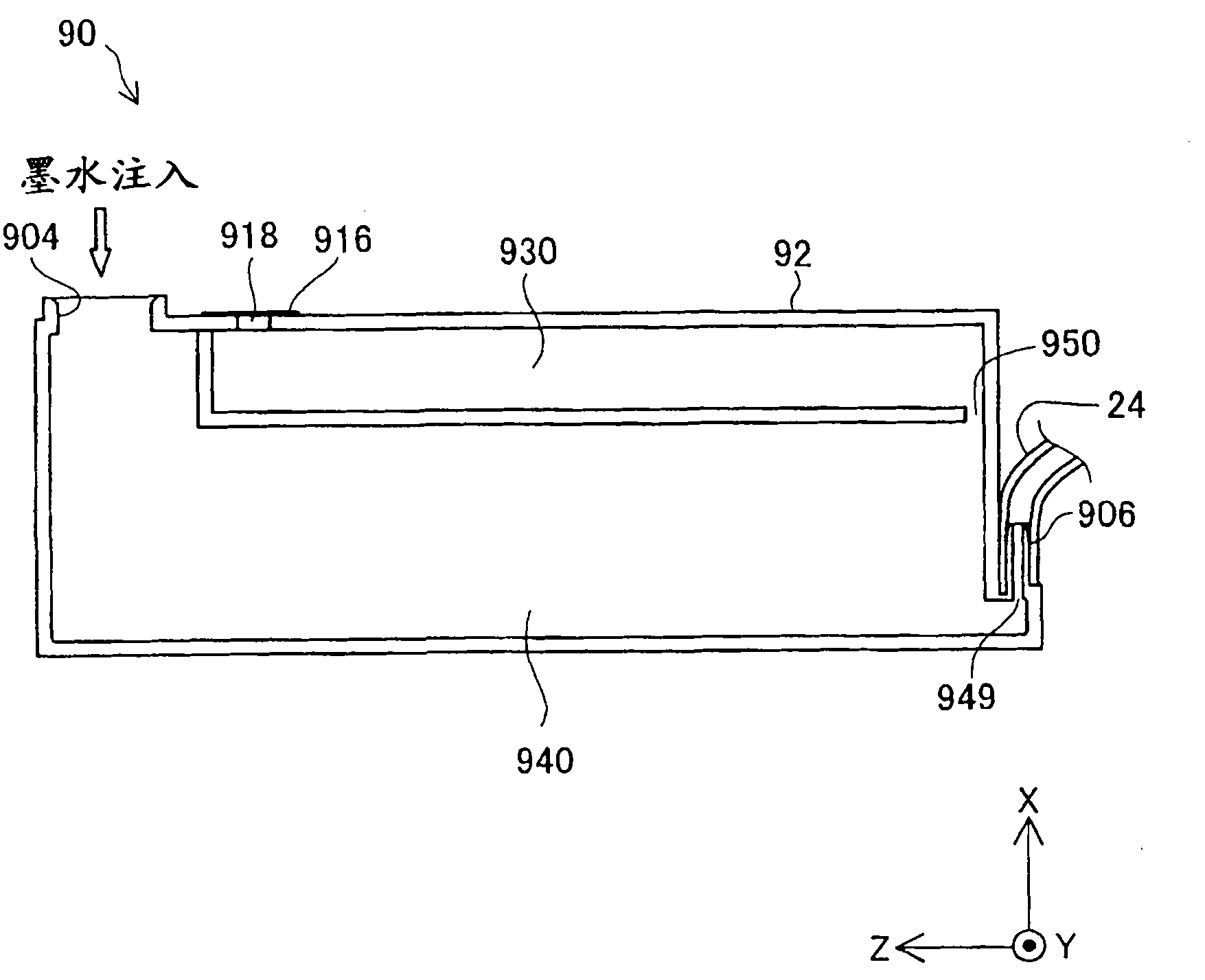

[0095] Figure 11 It is a diagram for explaining the ink tank 30a of the second embodiment. Figure 11 (A), (B) are the same as the first embodiment Figure 7 (A) Corresponding graph. Figure 11 (B) is a figure for explaining the state of the ink tank 30a when the injection amount of ink is too much. The difference from the ink tank 30 of the first embodiment lies in the structure of the liquid storage chamber 340a and the height position of the liquid injection port 304a in the injection posture. The other structures are the same as those of the first embodiment, so the same reference numerals are assigned and explanations are omitted. In addition, the ink tank 30a of the second embodiment is also used in the liquid ejection system 1 ( figure 2 ). Also, for ease of understanding, Figure 11 In (A), the plug member 302 is shown by a dotted line.

[0096] Such as Figure 11 As shown in (A), the liquid injection port 304 a is formed in the tank body 32 so as to be lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com