Method for adhering touch screen and display panel

A technology for display panels and touch screens, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve problems such as difficult control of the thickness of the adhesive layer, troublesome gluing process, and difficulty in achieving a uniform thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

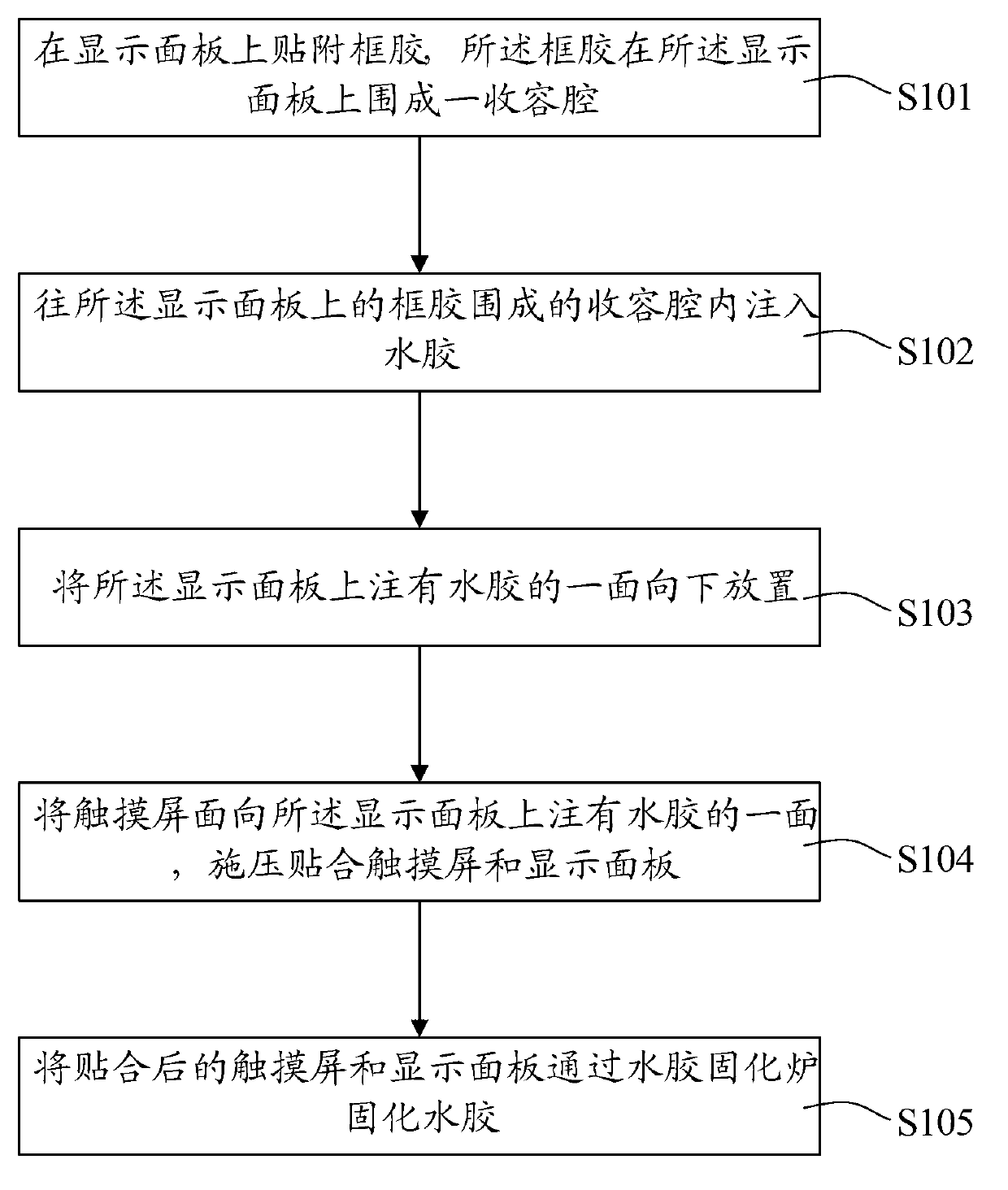

[0034] like figure 1 As shown, it is a flowchart of steps of a bonding method of a touch screen and a display panel in a preferred embodiment of the present invention, including the following steps:

[0035] Step S101 , sticking a frame glue on the display panel, the frame glue enclosing a receiving cavity on the display panel.

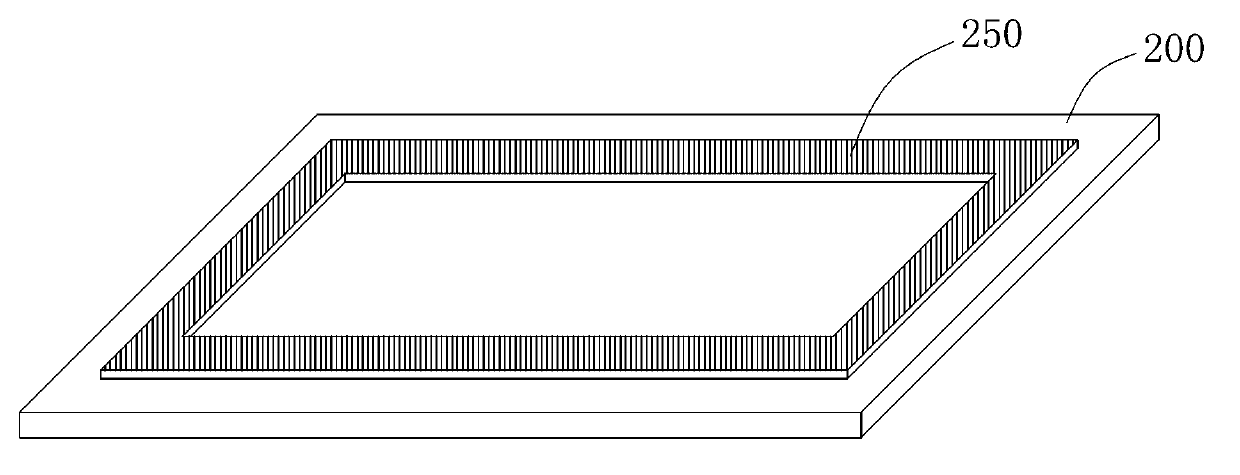

[0036] The frame glue may be double-sided glue, or semi-cured glue or developed and cured glue. like figure 2 As shown, it is a schematic structural view of the display panel 200 after the sealant 250 is pasted. Since the sealant 250 has a certain thickness, the sealant 250 forms a receiving cavity with a rectangular or circular cross section on the display panel 200 .

[0037] Step S102, injecting water glue into the receiving cavity surrounded by the frame glue on the display panel.

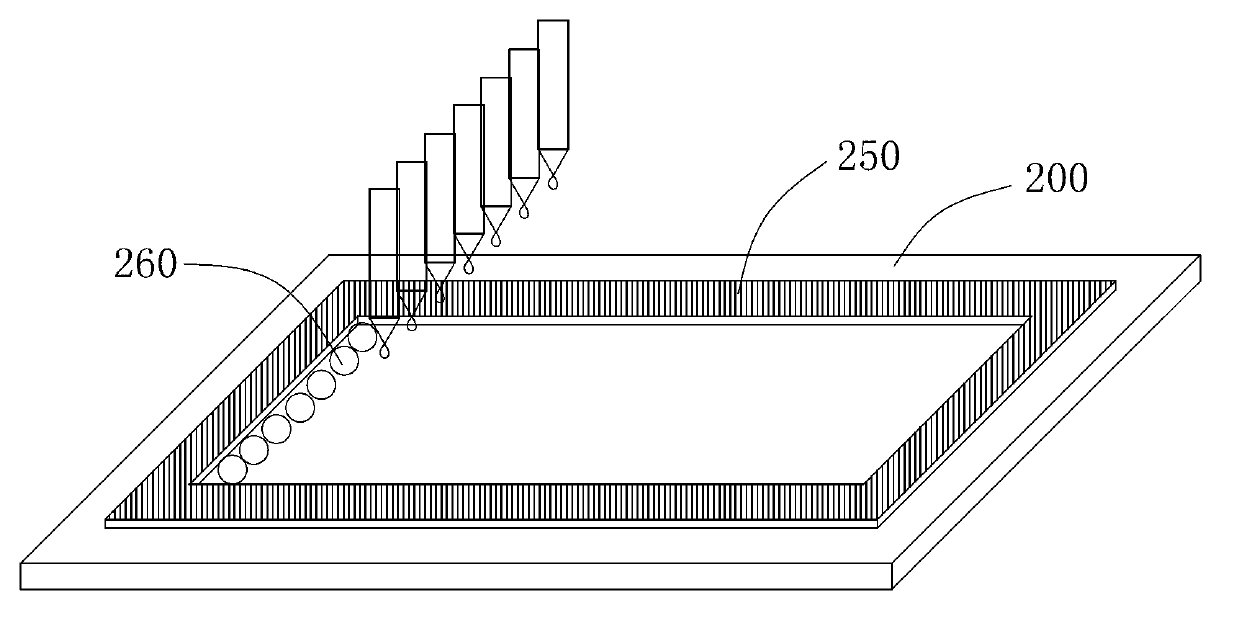

[0038] like image 3 shown in the figure 2 Shown is a schematic diagram of the action of injecting water glue 260 into the frame glue 250 on the display panel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com