Food waste recycling processor

A food waste and processor technology, which is applied in grain processing, chemical instruments and methods, presses, etc., can solve the problem of poor back-stirring effect of food waste, difficult extrusion and separation of water in food waste, and impact on food waste treatment Effect and other issues, to achieve the effect of ensuring cleanliness and crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

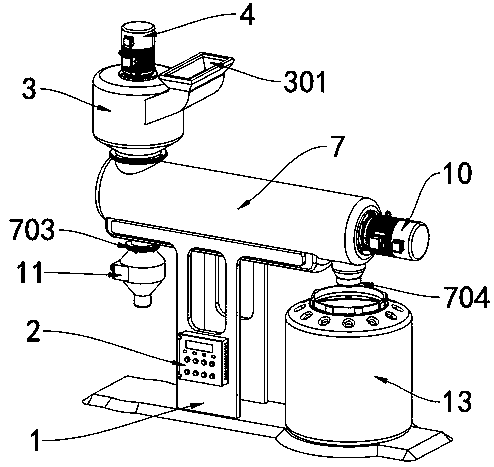

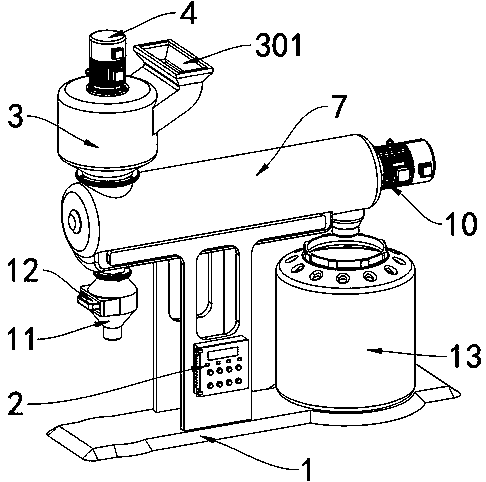

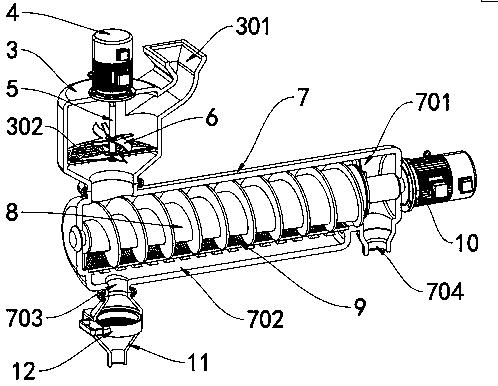

[0031] as attached figure 1 to attach Figure 10 Shown:

[0032]The invention provides a waste recycling processor, comprising a support frame 1, a crushing cylinder 3, a cone screw conveying shaft 8, a conveying motor 10, a filter tube 11, a garbage fermentation tank 13 and a tank cover 14; the front end of the support frame 1 is installed There is a control electric box 2, and the control electric box 2 is electrically connected with the pulverizing motor 4 and the conveying motor 10 respectively through the power line; There is a feeding port 301, and the pulverizing motor 4 is installed on the top end surface of the pulverizing cylinder 3; a sorting filter plate 302 is arranged inside the pulverizing cylinder 3, and the bottom of the rotating shaft 5 is connected to the inside of the sorting filter plate 302, and the pulverizing knife 6 rotates On the top of the sorting filter plate 302, the meal waste crushed inside the crushing cylinder 3 can be filtered through the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com