Crushing device for recycling construction waste

A pulverizing device and construction waste technology, applied in grain processing and other directions, can solve the problems of flying environment, large particle size, unfavorable construction waste recycling and other problems, and achieve the effect of ensuring the pulverizing effect and improving the grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

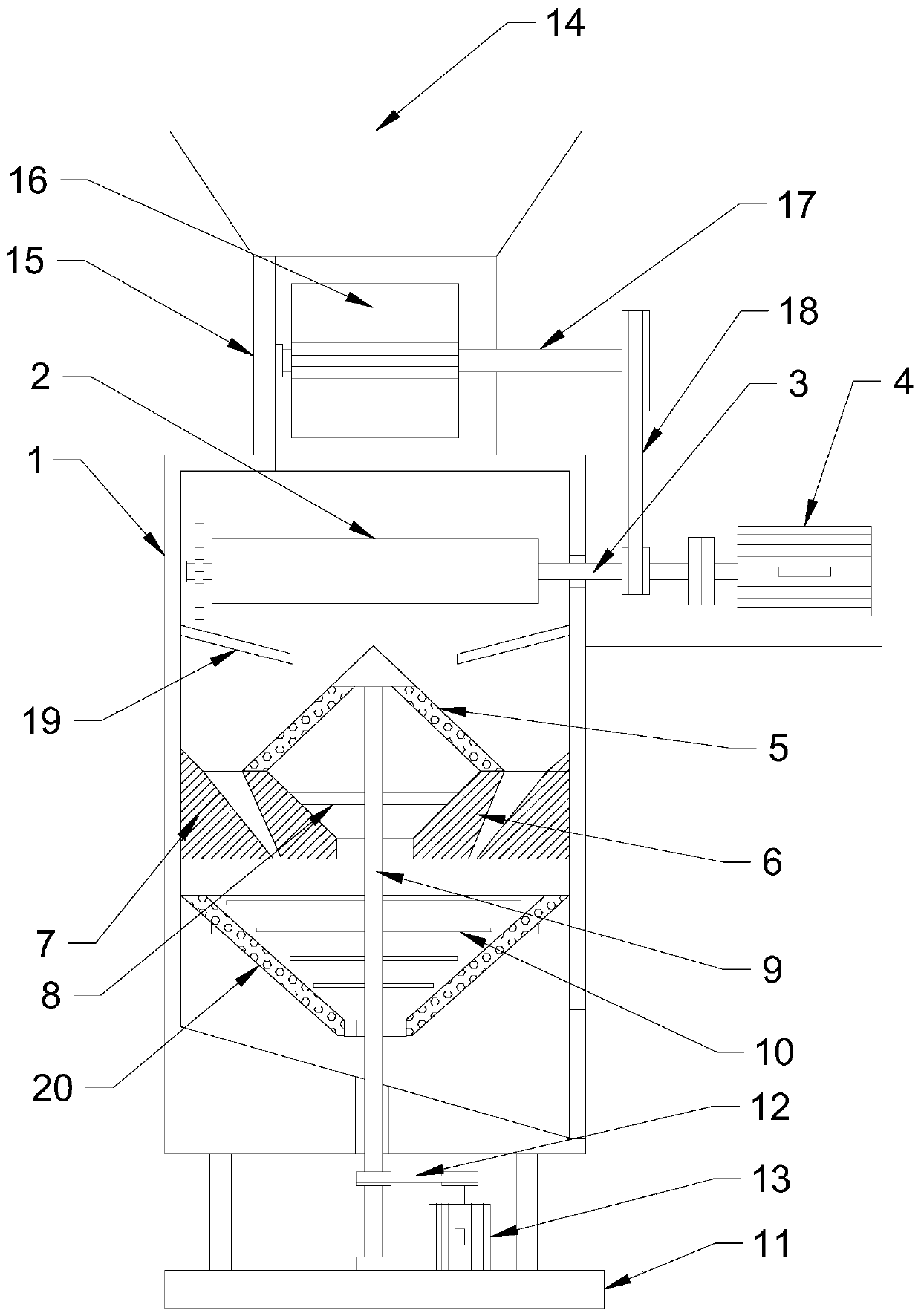

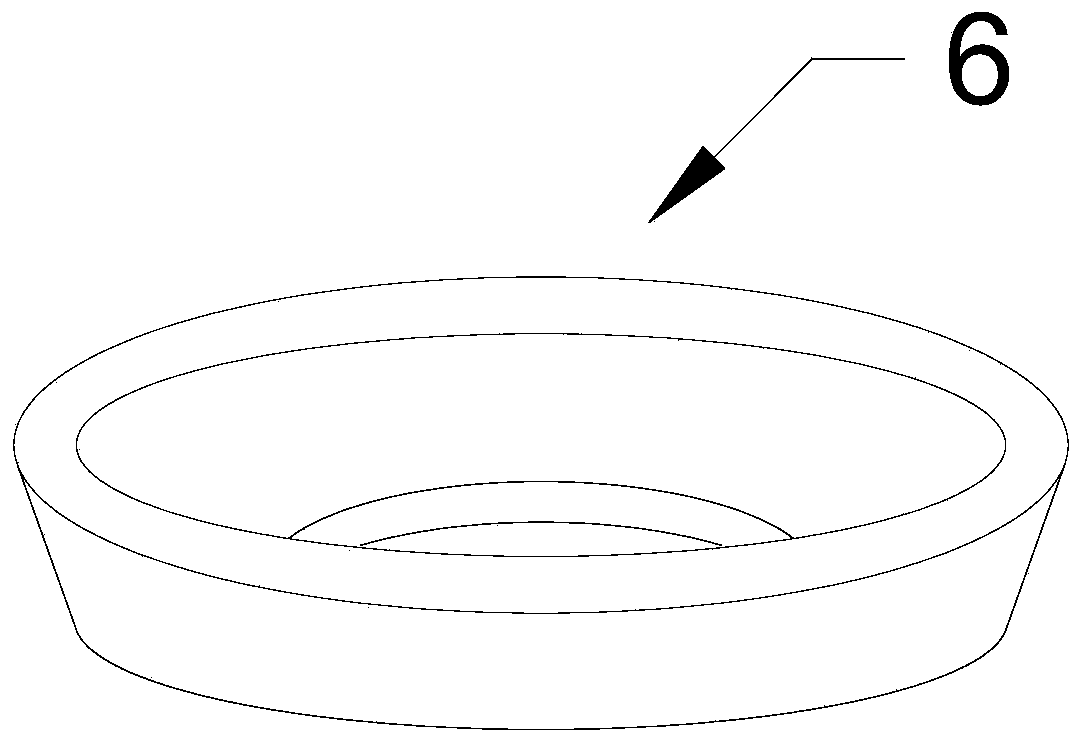

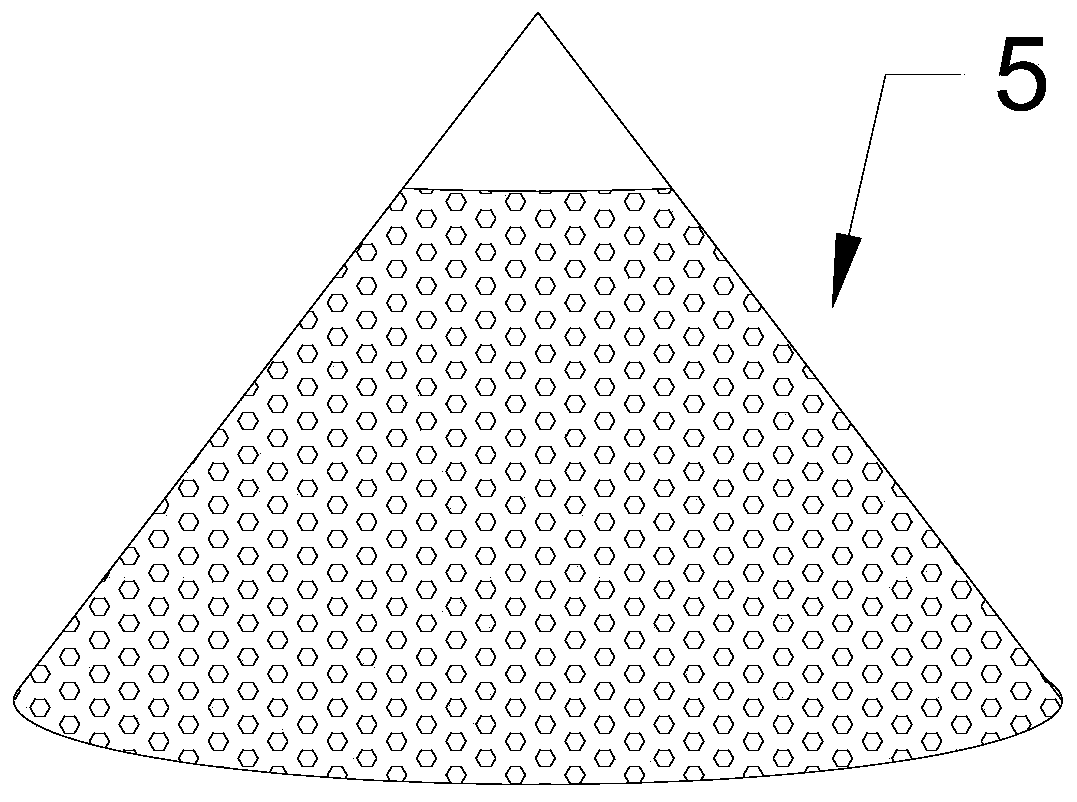

[0023] see Figure 1~4 In an embodiment of the present invention, a crushing device for recycling construction waste includes a crushing box 1 and crushing rollers 2; the crushing box 1 is provided with multiple groups of crushing rollers 2 arranged longitudinally, and the crushing rollers 2 are connected to each other through a transmission shaft 3 The inner wall of the crushing box 1 is rotationally connected, the transmission shaft 3 extends to the outside of the crushing box 1 and is connected to the first drive motor 4 through a coupling, and the first drive motor 4 is fixedly connected to the crushing box 1 by means of bolts; the crushing roller 2. There is an upward convex screen cover 5 at the bottom. The upward convex screen cover 5 is a hollow conical screen cover for preliminary screening of the broken concrete blocks, and small particles of concrete enter the upper convex screen through the screen holes. In the screen cover 5, the concrete blocks of large particles...

Embodiment 2

[0028] see figure 1 and Figure 5 The difference between this embodiment and Embodiment 1 is that: the upper end of the crushing box 1 is connected with a feeding hopper 14 through a feeding box 15, and a feeding impeller 16 is arranged in the feeding box 15, and the feeding impeller 16 includes a driven shaft 17 And the rectangular blades distributed in the circumferential direction, the driven shaft 17 extends to the outside of the lower material box 15 and is connected to the transmission shaft 13 through the second transmission belt 18. When crushing, the feeding speed of the concrete block is controlled to ensure the crushing effect. At the same time, it reduces dust spillage and protects the environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com