Medicine grinding equipment for pediatric medical treatment

A medical and drug technology, applied in the field of pediatric medical drug grinding equipment, can solve the problems of multi-drug powder, easy to produce danger, etc., and achieve the effect of improving the grinding effect and convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

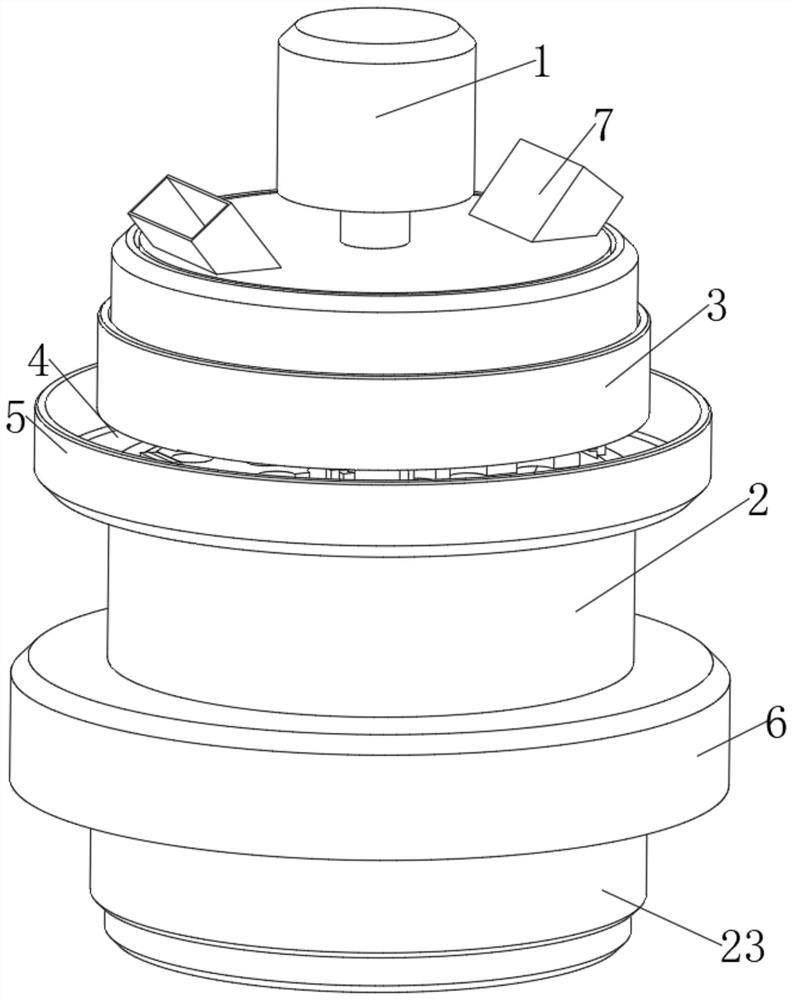

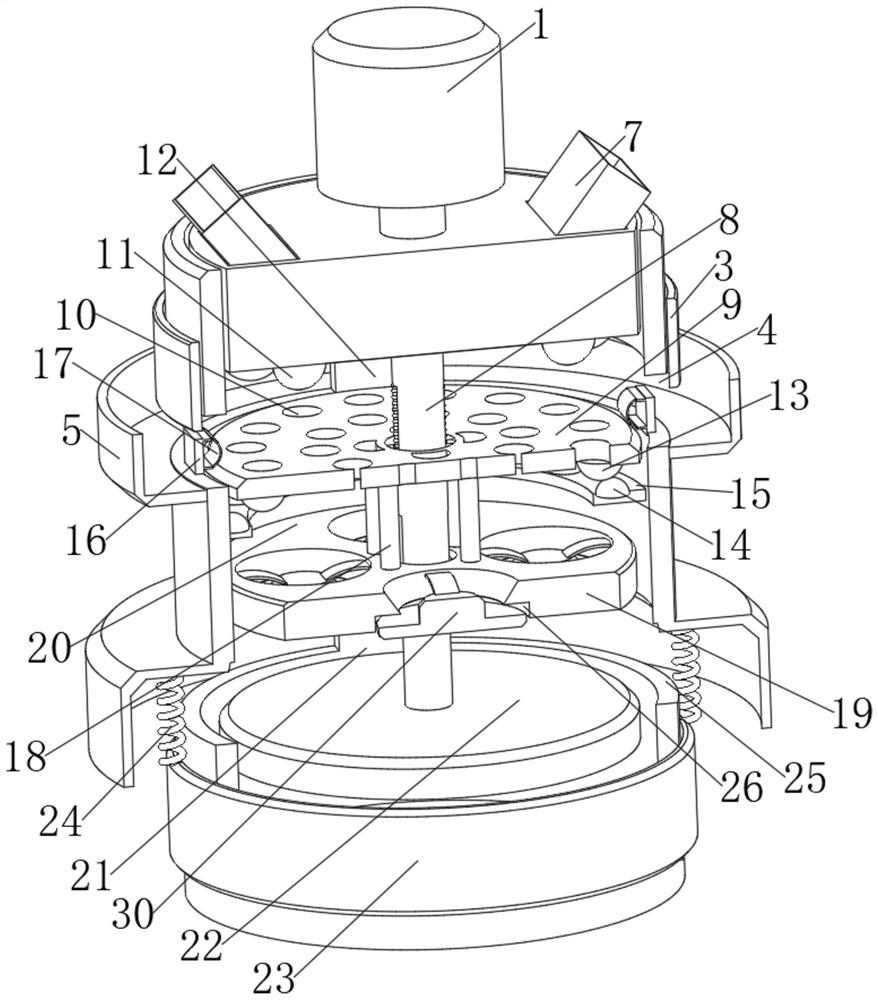

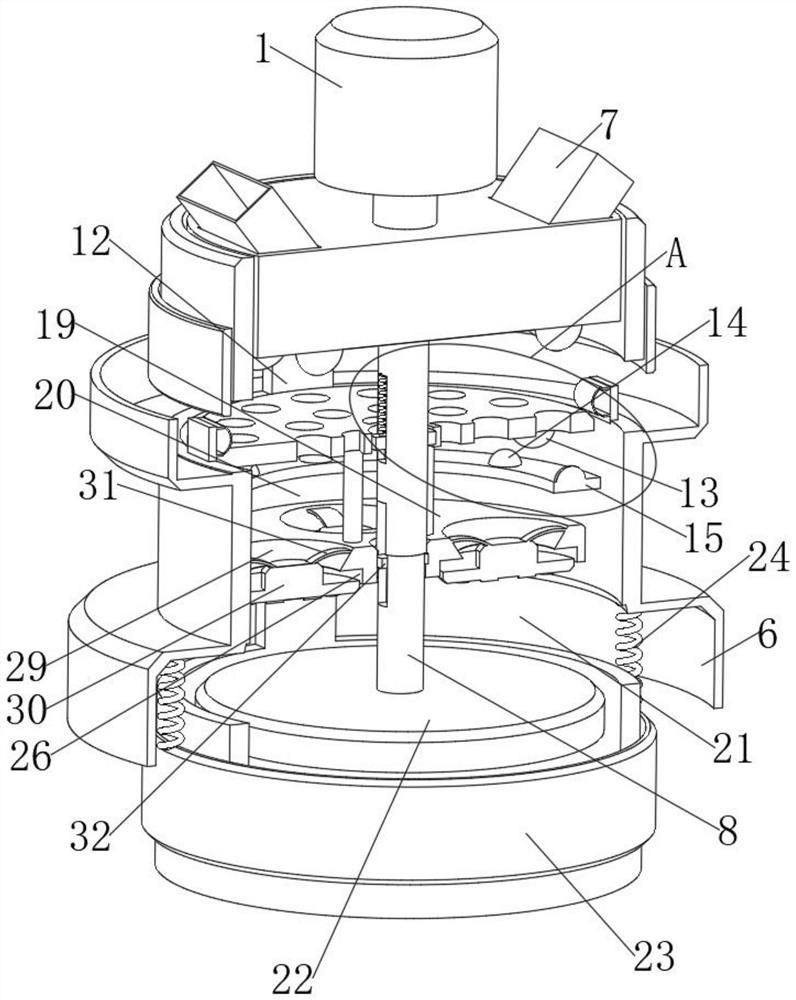

[0030] The capsule shell is removed by the extrusion of the extrusion plate 9, and the rotating shaft 8 will also drive the extrusion plate 9 to rotate, and then the extrusion plate 9 will drive the medicine to rotate and rub against the top of the grinding tank 2, so that the medicine in the capsule passes through the leakage The hole 10 falls into the inside of the grinding tank 2, which is convenient for subsequent grinding, so that the device can grind medicines in multiple functions, please refer to Figure 1-2 , including the grinding tank 2 and the small motor 1 installed on the grinding tank 2, the interior of the grinding tank 2 is rotatably connected with a rotating shaft 8, the rotating shaft 8 is connected with the output shaft of the grinding tank 2, and the rotating shaft 8 is installed with a squeeze Plate 9, a processing cavity 12 for processing capsules is formed between the extrusion plate 9 and the grinding tank 2, the extrusion plate 9 is used for extrusion ...

Embodiment 2

[0035] The pressing plate 9 drives the medicine to hit the top of the grinding tank 2 quickly, so as to increase the pressing force of the pressing plate 9, so that the pressing plate 9 can better separate the capsule skin from the medicine. The example is an improvement made on the basis of Example 1. For details, please refer to Figure 1-4 , the rotating shaft 8 is also slidably connected with a first sliding block 28, a second spring 27 is also installed on the rotating shaft 8, the second spring 27 is connected with the first sliding block 28, and the pressing plate 9 is connected with the first sliding block 28 In connection, a vertical plate 16 is also installed on the inner wall of the grinding tank 2 , an arc-shaped elastic sheet 17 is installed on the vertical plate 16 , and the extrusion plate 9 is used to abut against the arc-shaped elastic sheet 17 .

[0036] Increase the squeezing force: according to image 3 and Figure 4 As shown, the first slider 28 on the p...

Embodiment 3

[0038] The withholding plate 19 is rotated through the transmission of the connecting rod 18, and the medicine is processed by the extrusion and rotation of the withholding plate 19, thereby improving the grinding effect of the medicine. This embodiment is an improvement made on the basis of the second embodiment. Specifically, see Figure 1-4 , a connecting rod 18 is also installed on the extrusion plate 9, the connecting rod 18 is connected with a withholding plate 19, and the withholding plate 19 is provided with a circular hole 26, and the circular hole 26 is used for circulating medicinal powder;

[0039] Between the withholding plate 19 and the pressing plate 9, a transfer bin 20 for storing medicinal powder is formed, and a grinding plate 22 is also installed on the rotating shaft 8, and a grinding bin 21 for grinding medicinal powder is formed between the grinding plate 22 and the withholding plate 19, The round hole 26 is used to transfer the powder to the grinding pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com