Solid building waste crushing and recycling device

A construction waste and recycling device technology, applied in construction waste recycling, solid waste removal, solid separation and other directions, can solve the problems of affecting recycling, incomplete waste crushing, etc. The effect of start-stop operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

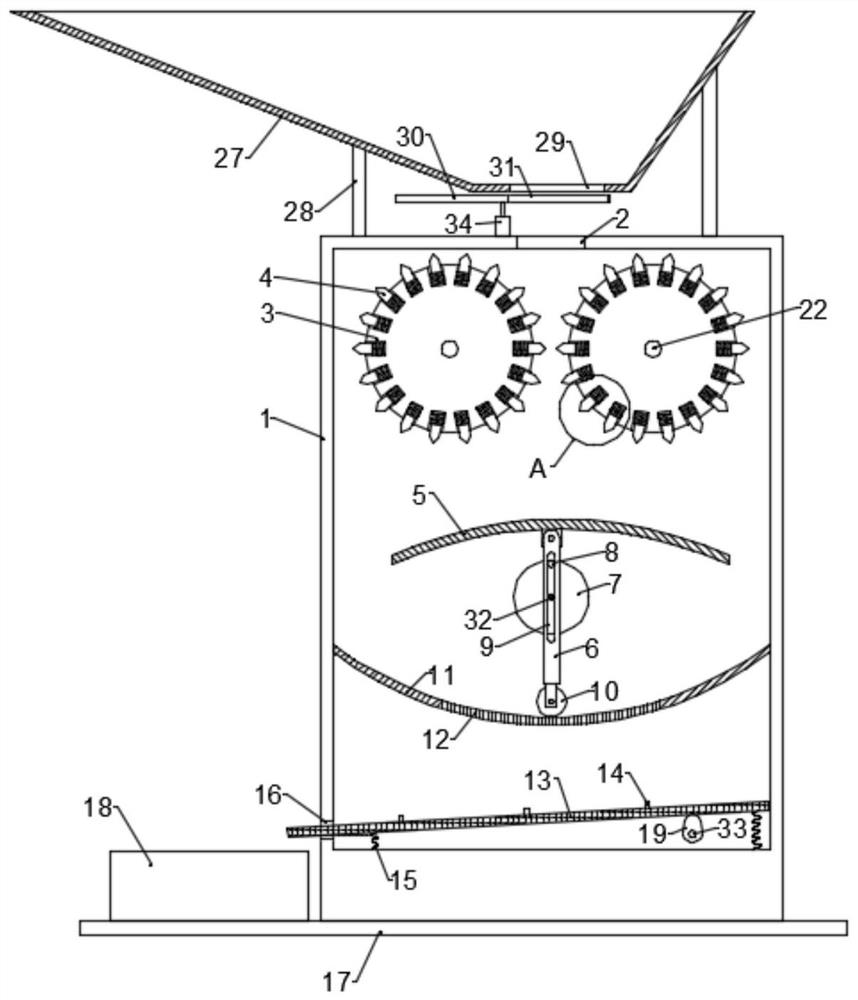

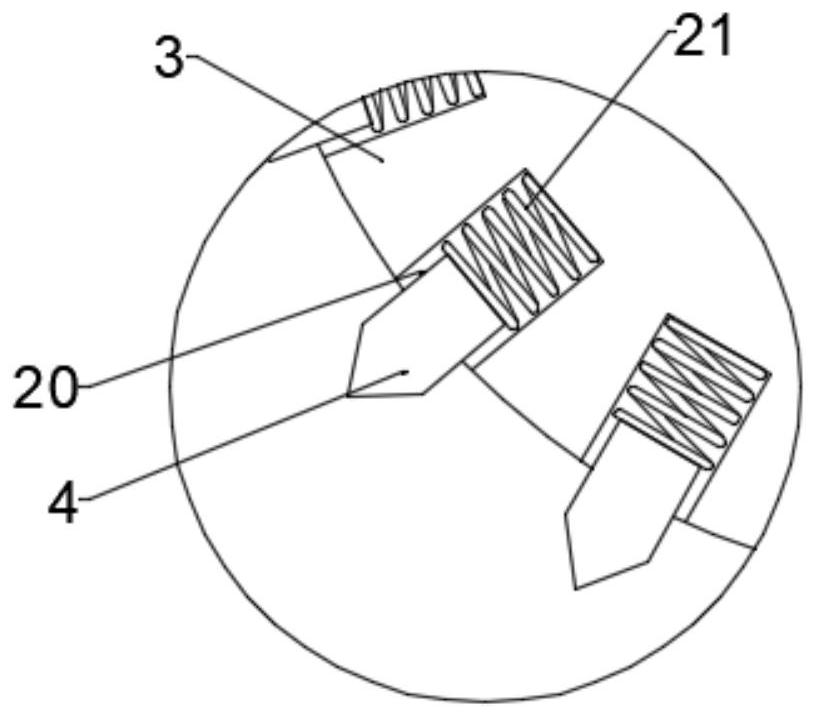

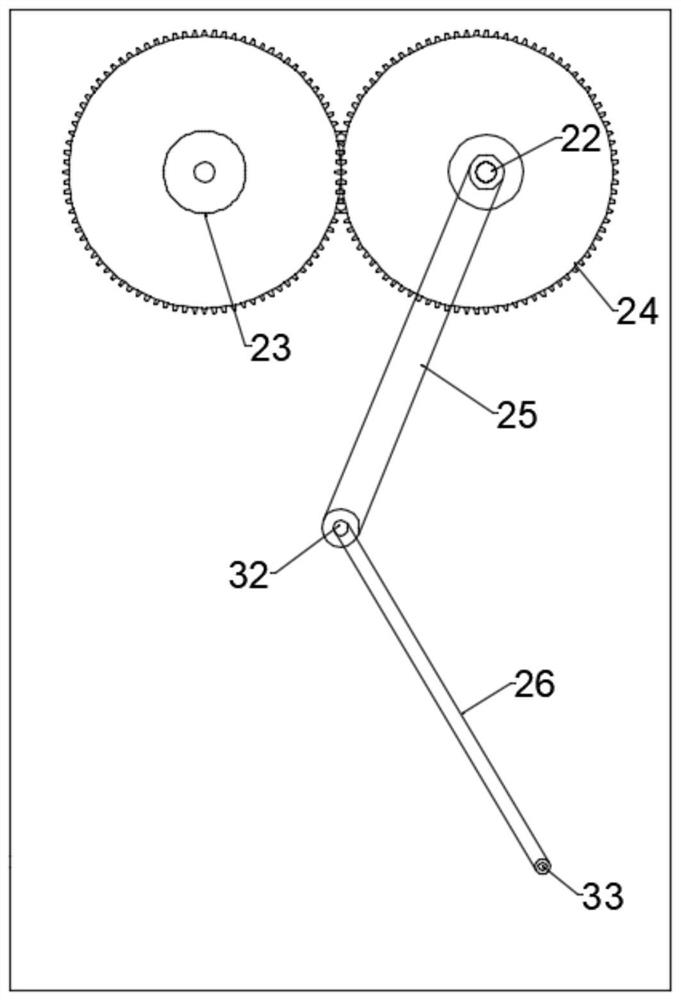

[0023] see Figure 1~4 , in an embodiment of the present invention, a solid construction waste crushing and recycling device includes a base 17 and a main box 1 fixed to the base 17; the top shell wall of the main box 1 is provided with a feed port 2, and Two crushing rollers 3 arranged symmetrically are arranged above the inner cavity of the casing 1. The crushing rollers 3 are connected to the main casing 1 through the rotation of the first rotating shaft 22. The crushing rollers 3 are evenly distributed with crushing teeth 4. The two crushing rollers The gap between 3 is facing the feed inlet 2, and the middle part of the inner cavity of the main box body 1 is fixed with a deflector 5, and the lower part of the deflector 5 is provided with an arc-shaped pressure plate 11 at intervals, and a blanking hole is opened on the pressure plate 11 12. The central position of the bottom of the deflector 5 is rotatably connected to a swing frame 6, and the bottom of the swing frame 6 ...

Embodiment 2

[0031] This embodiment expands the functions on the basis of Embodiment 1, specifically:

[0032] The top of the main box body 1 is also provided with a material frame 27, the material frame 27 is fixed on the top of the main box body 1 by a bracket 28, and the bottom shell wall of the material frame 27 is provided with a discharge port facing the feed port 2 29. It can facilitate the placement of waste.

[0033] Further, the bottom of the material frame 27 is also fitted with a disk 30, one side of the disk 30 is provided with a through hole 31 matching the discharge port 29, and the top of the main box 1 is installed with a second Motor 34, the output end of the second motor 34 is connected with disc 30, during work, drives disc 30 to rotate by second motor 34, and when through hole 31 rotates to the position relative to discharge port 29, waste passes through material The frame 27 falls into the main box body 1, and when the through hole 31 rotates to a position staggered fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com