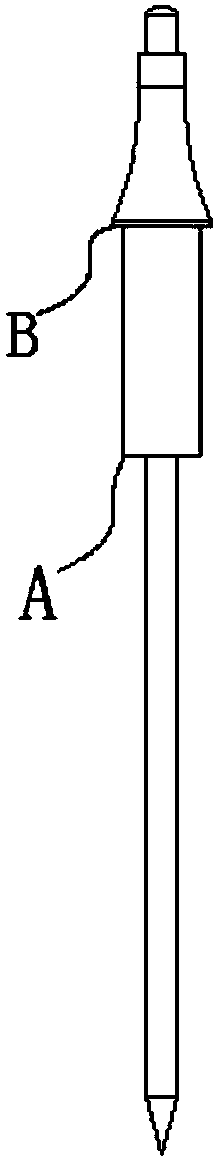

Water diversion core staggered material receiving device and method

A technology of feeding device and water guiding core, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the feeding speed cannot be too fast, the water guiding core is stuck, and it is difficult to select, so as to eliminate the problem of collision and jump, The effect of reducing the probability of jamming and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

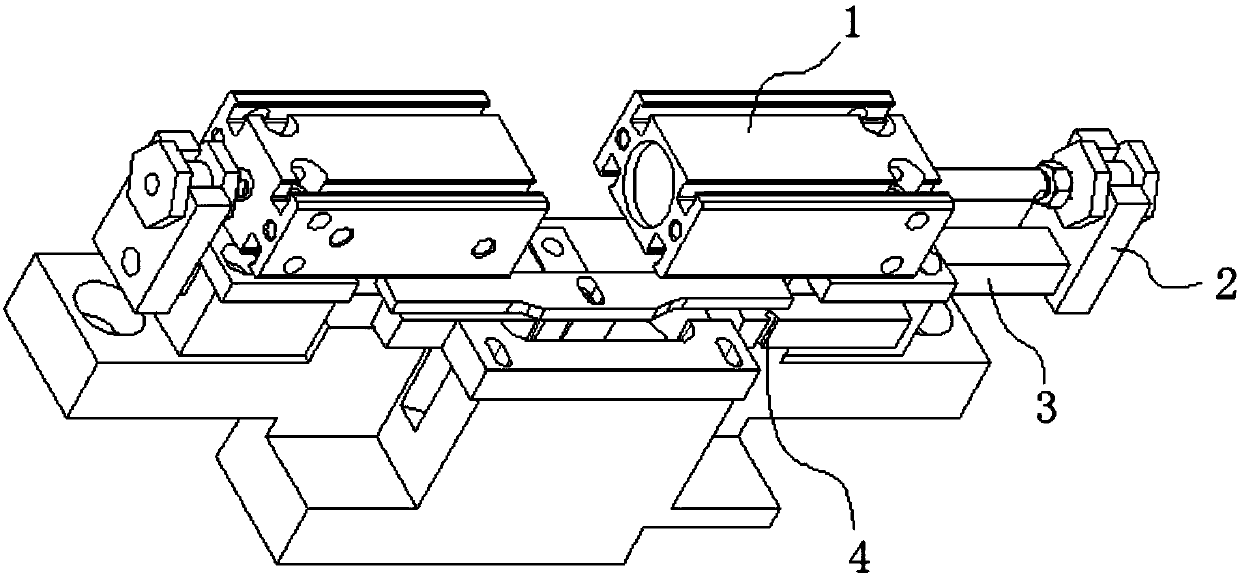

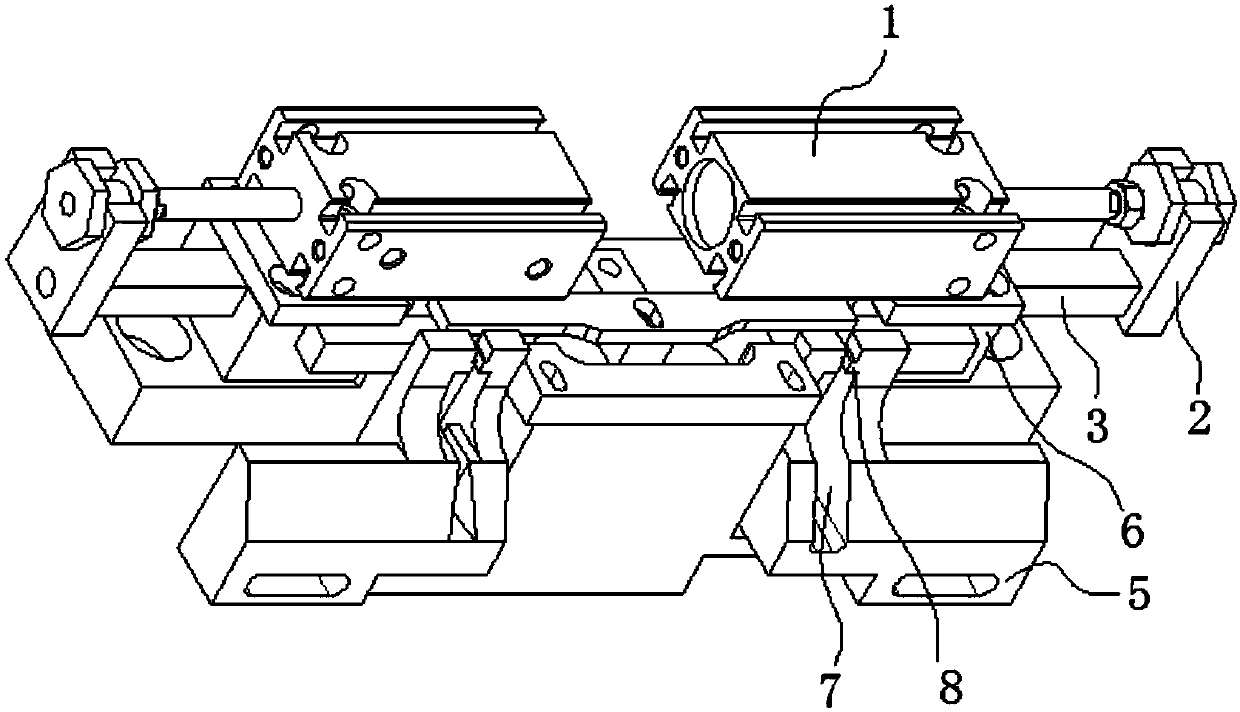

[0030] The technical solutions of the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings of the present invention.

[0031] The dislocation material receiving device and method of the water diversion core disclosed in the present invention, by adding a transfer piece to the dislocation mechanism, the material coming out of the discharge port of the vibrating material plate is firstly delayed into the transfer piece, and then the transfer piece is transferred to the transfer piece through the transfer piece. On the dislocation mechanism, the jumping problem of the water diversion core on the dislocation mechanism is eliminated, the fixed posture of the water diversion core is fixed, and the probability of material jamming during dislocation is reduced.

[0032] combine Figure 3 to Figure 5 As shown in the figure, a dislocation material receiving device for the water guiding core disclosed in the embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com