Medical glass bottle breaking and disinfecting apparatus

A technology of disinfection device and glass bottle, applied in the direction of chemistry, grain processing, etc., can solve the problems of incomplete crushing, bacterial diffusion, pollution, etc., and achieve the effect of ensuring the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

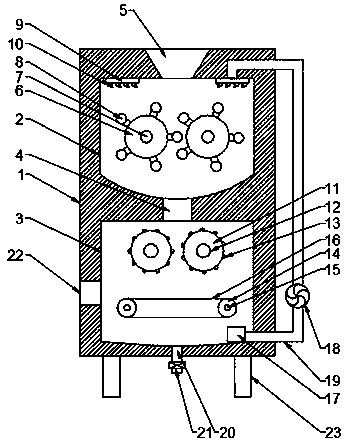

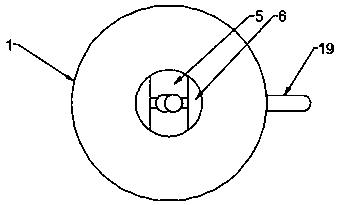

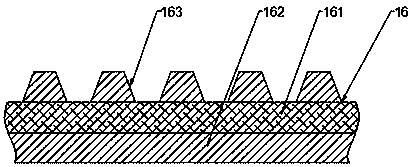

[0022] see Figure 1~3 , a glass bottle crushing and disinfection device for medical use, comprising a body 1, a crushing chamber 2 and a crushing chamber 3 are arranged in the body 1, the crushing chamber 2 is arranged above the crushing chamber 3, and the crushing chamber 2 communicates with The hole 4 is connected to the crushing chamber 3, and the top wall of the crushing chamber 2 is connected to the feeding hole 5. The feeding hole 5 is a tapered hole, and the left and right sides of the top wall of the crushing chamber 2 are symmetrically equipped with spraying devices 9. A number of high-pressure nozzles 10 are uniformly arranged on the spraying device 9, and all of the high-pressure nozzles 10 are inclined toward the direction of the feeding hole 5, and crushing rollers 6 are symmetrically arranged in the crushing chamber 2, and the crushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com