Multi-channel automatic quantitative sterile sampling device and bioreactor with same

A bioreactor and sampling device technology, applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, method of supporting/immobilizing microorganisms, etc., can solve the problem of insufficiency of multi-channel bioreactor sampling It can shorten the sampling operation time, reduce equipment cost and maintenance workload, and simplify the connection pipeline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

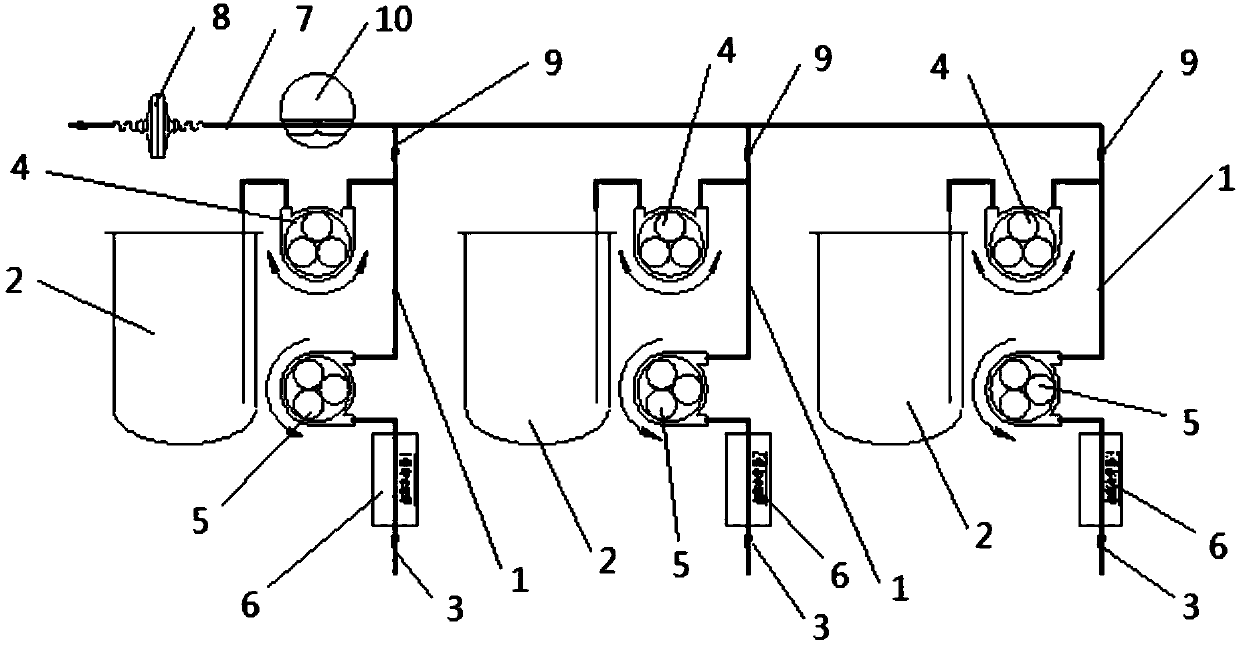

[0036] see figure 1, a multi-channel automatic quantitative aseptic sampling device, used to sample the reactants in the multi-channel bioreactor 2, including: a plurality of sampling pipelines 1, one end is respectively located in a different bioreactor 2, and the other end is a sample outlet 3; the first peristaltic pump 4 is arranged on each of the sampling pipelines 1, and is located between the bioreactor 2 and the sample outlet 3; the second peristaltic pump 5 is arranged on each of the sampling pipelines 1, and Located between the first peristaltic pump 4 and the sample outlet 3; the heating cooler 6 is respectively arranged on each sampling pipeline 1, and is located between the second peristaltic pump 5 and the sample outlet 3; the main gas pipeline 7 is connected to the The air filter 8 is provided with a plurality of gas sub-pipelines 9 at the other end, and each gas sub-pipeline 9 communicates with one of the sampling pipelines 1 respectively, and the connection is...

Embodiment 2

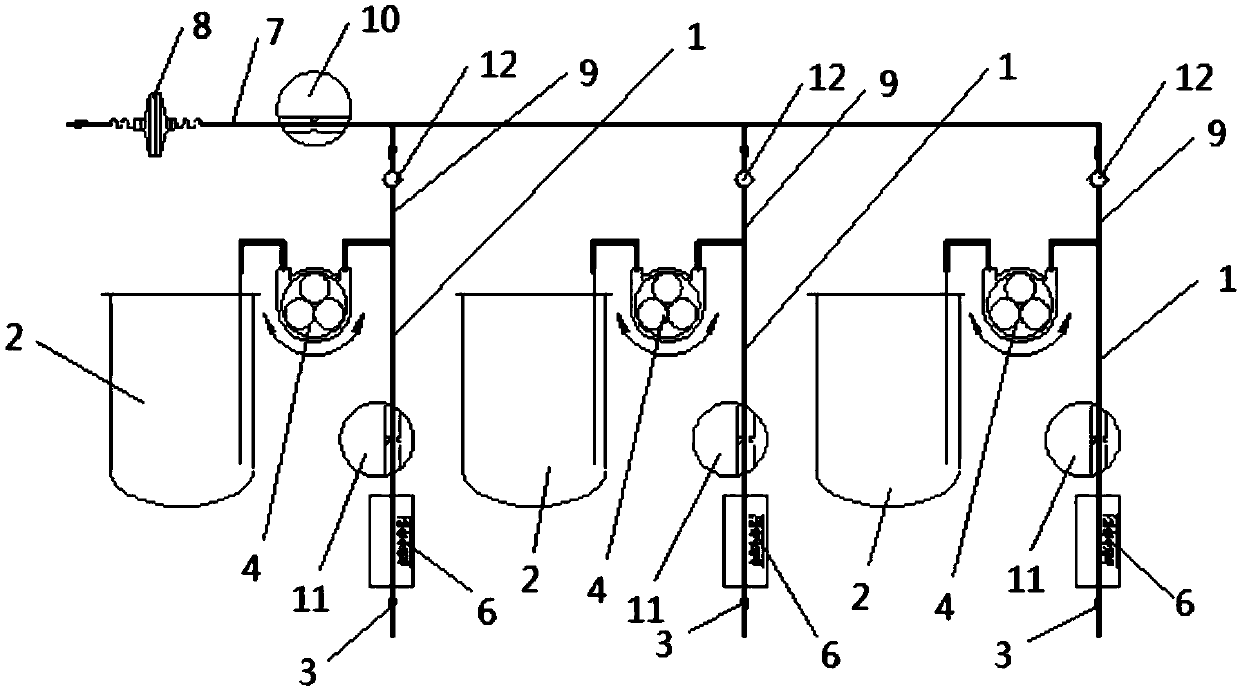

[0049] see figure 2 , which is a schematic structural view of a multi-channel automatic quantitative aseptic sampling device provided in another embodiment of the present invention.

[0050] In this embodiment, the multi-channel automatic quantitative aseptic sampling device is used to sample the reactants in the multi-channel bioreactor 2, including: a plurality of sampling pipelines 1, one end of which is respectively located in different bioreactors 2, The other end is a sample outlet 3; the first peristaltic pump 4 is arranged on each of the sampling pipelines 1, and is located between the bioreactor 2 and the sample outlet 3; the second pinch valve 11 is arranged on each of the On the sampling pipeline 1, and between the first peristaltic pump 4 and the sample outlet 3; the heating cooler 6, respectively, on each sampling pipeline 1, and between the second pinch valve 11 and the sample outlet 3; gas The main pipeline 7 is connected to the air filter 8 at one end, and a ...

Embodiment 3

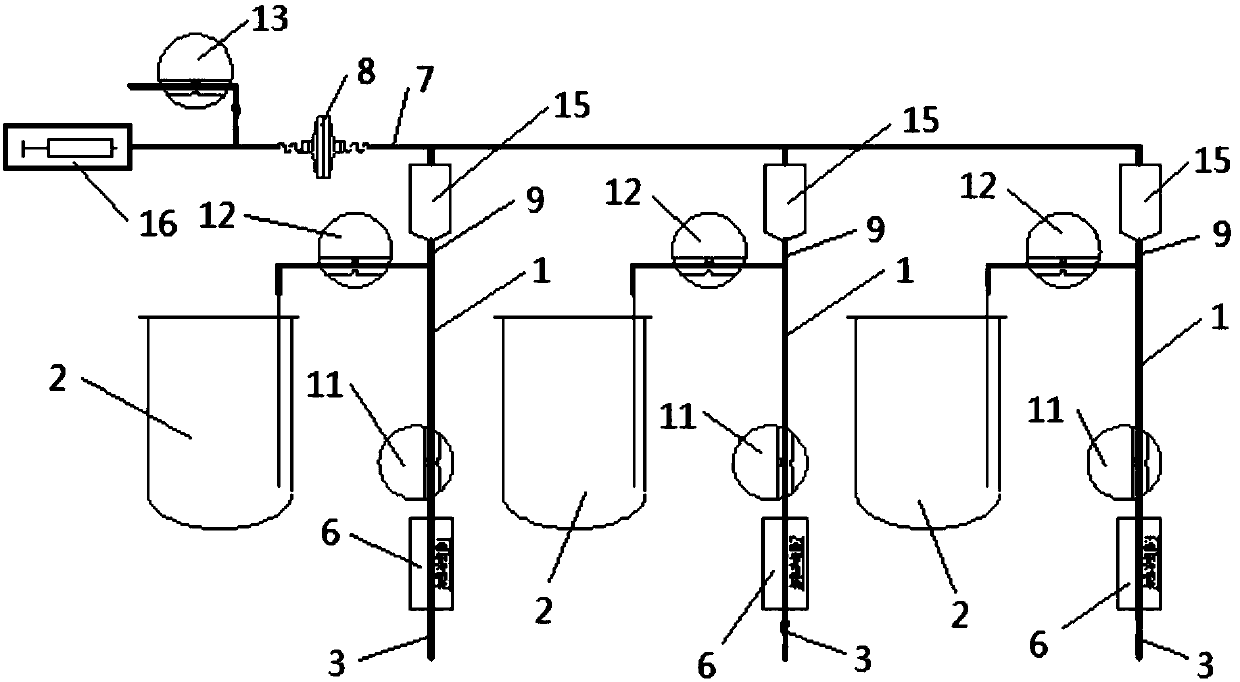

[0053] see image 3 , which is a schematic structural view of a multi-channel automatic quantitative aseptic sampling device provided in another embodiment of the present invention.

[0054] In this embodiment, the multi-channel automatic quantitative aseptic sampling device is used to sample the reactants in the multi-channel bioreactor 2, including: a plurality of sampling pipelines 1, one end of which is respectively located in different bioreactors 2, The other end is the sample outlet 3; the third pinch valve 12 is arranged on each of the sampling pipelines 1, and is located between the bioreactor 2 and the sample outlet 3; the second pinch valve 11 is arranged on each of the said sampling pipelines 1; On the sampling pipeline 1, and between the third pinch valve 12 and the sample outlet 3; the heating cooler 6 is respectively arranged on each sampling pipeline 1, and between the second pinch valve 11 and the sample outlet 3 The main gas pipeline 7 is provided with a fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com