Aseptic filling system

A filling machine, aseptic environment technology, applied in packaging sterilization, liquid bottling, packaging and other directions, can solve the problems of inability to maintain product quality, high efficiency, inconsistent product quality, etc., to reduce the installation space, reduce manufacturing costs, Effortlessly manageable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0066]

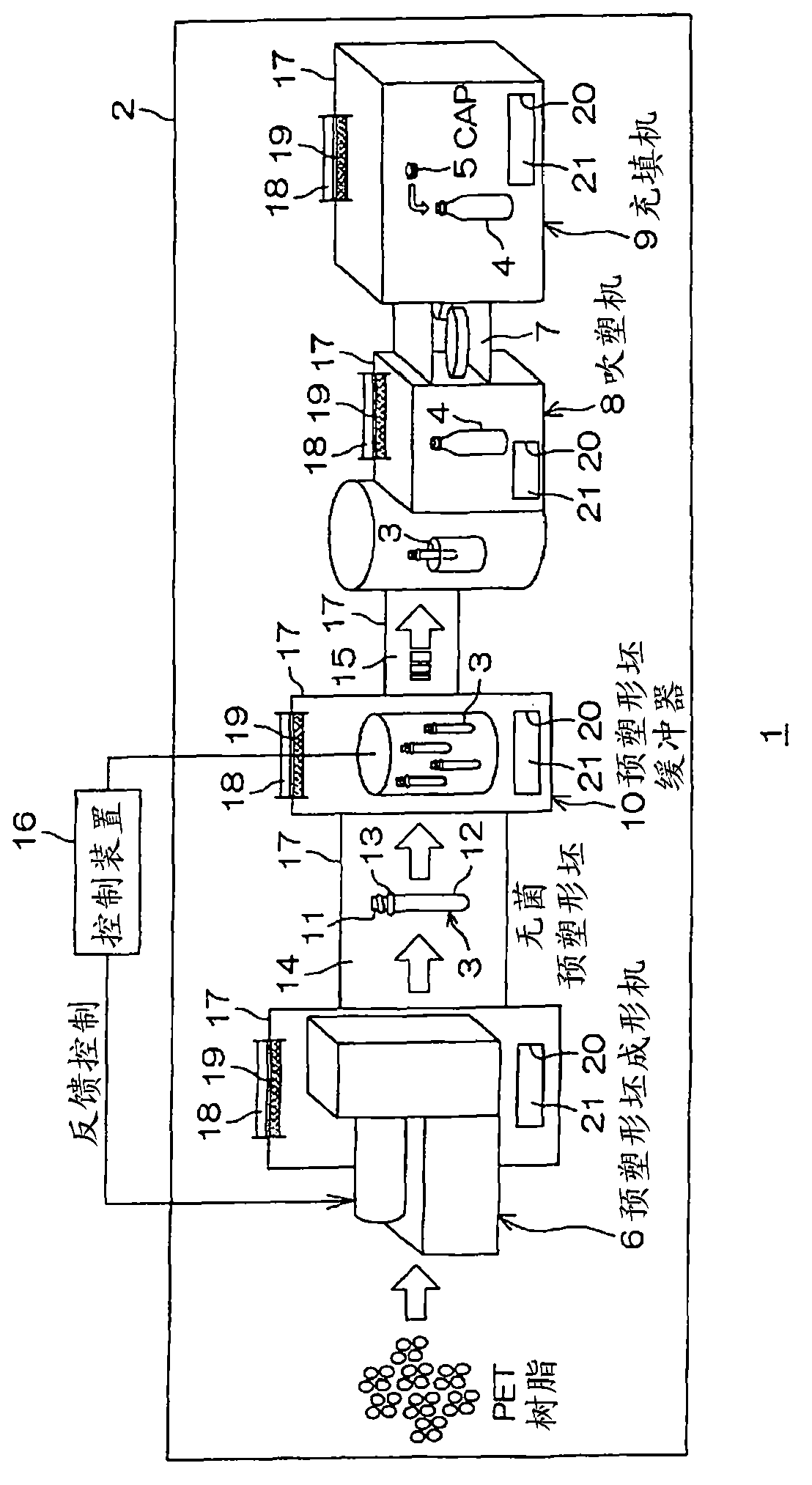

[0067] figure 1 It is a schematic configuration diagram of the aseptic filling system according to the first embodiment of the present invention.

[0068] The aseptic filling system 1 is set to pass, for example, ISO class 4 (the allowable concentration of particles with a diameter of 0.1 μm is 10,000 particles / ft 3 . ), ISO class 5 (the allowable concentration of particles with a diameter of 0.1 μm is 100,000 particles / ft 3 . ) consistent equipment to maintain cleanliness, and the room temperature is kept at about 20°C to 30°C in the clean room 2 with a sterile environment.

[0069] The aseptic filling system 1 forms a preform 3 made of PET resin raw material in the clean room 2, expands the preform 3 and turns it into a bottle, and fills the bottle 4 with drinking water and liquid nitrogen (LN 2 ), tighten the cap 5 (CAP), and accordingly, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com