Construction waste treatment device for environmental protection

A construction waste and processing device technology, applied in grain processing, drying gas arrangement, cleaning methods and appliances, etc., can solve the problems of reducing processing efficiency, hidden safety hazards, occupying land, etc., and achieve the effect of ensuring the crushing effect and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

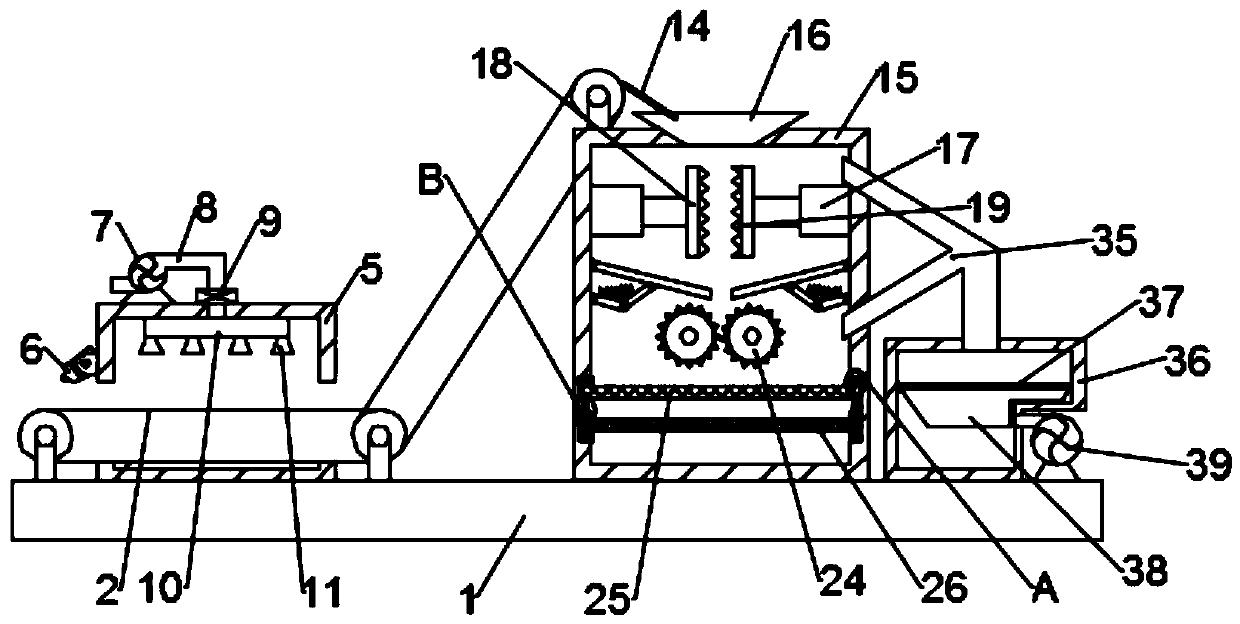

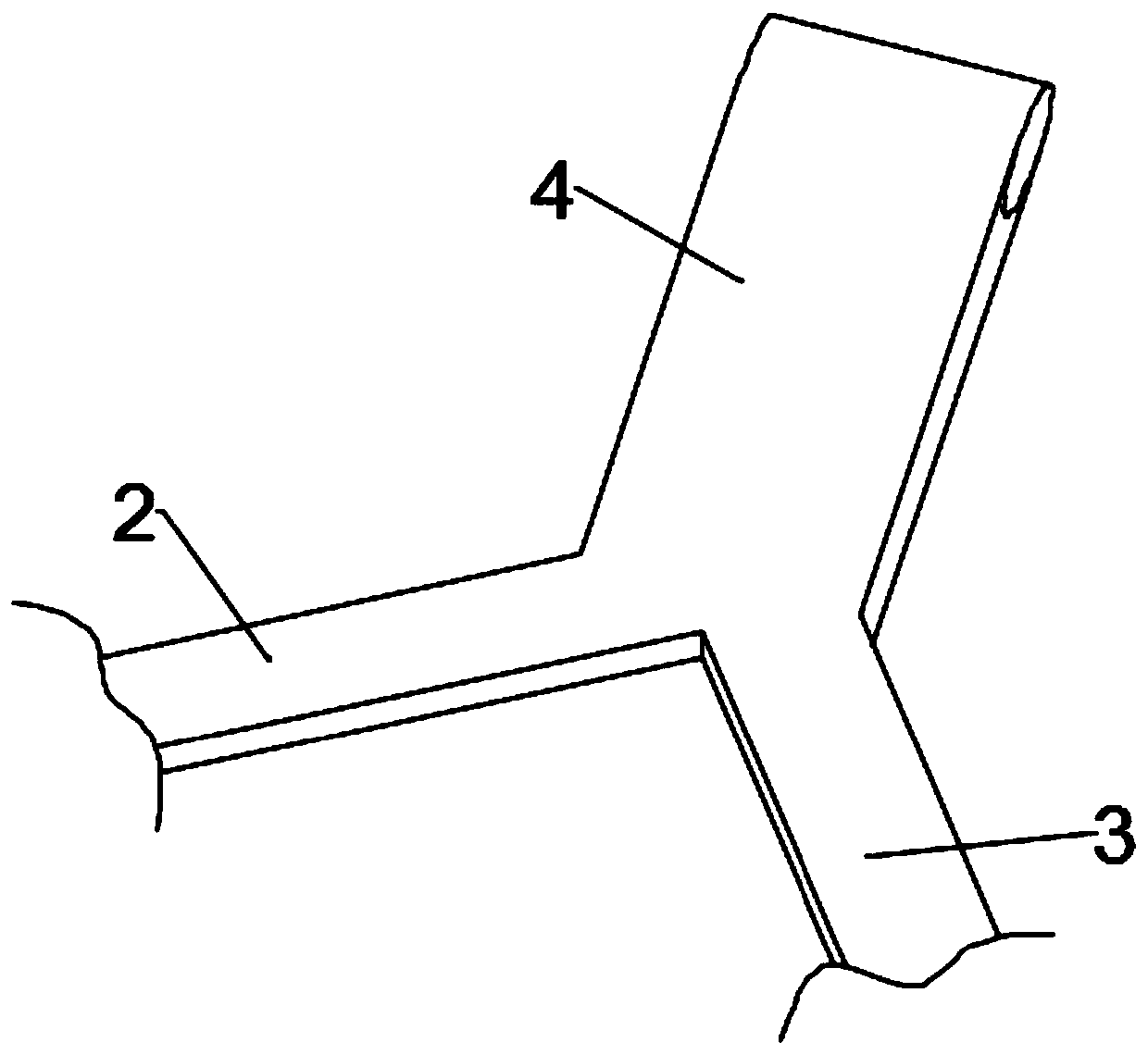

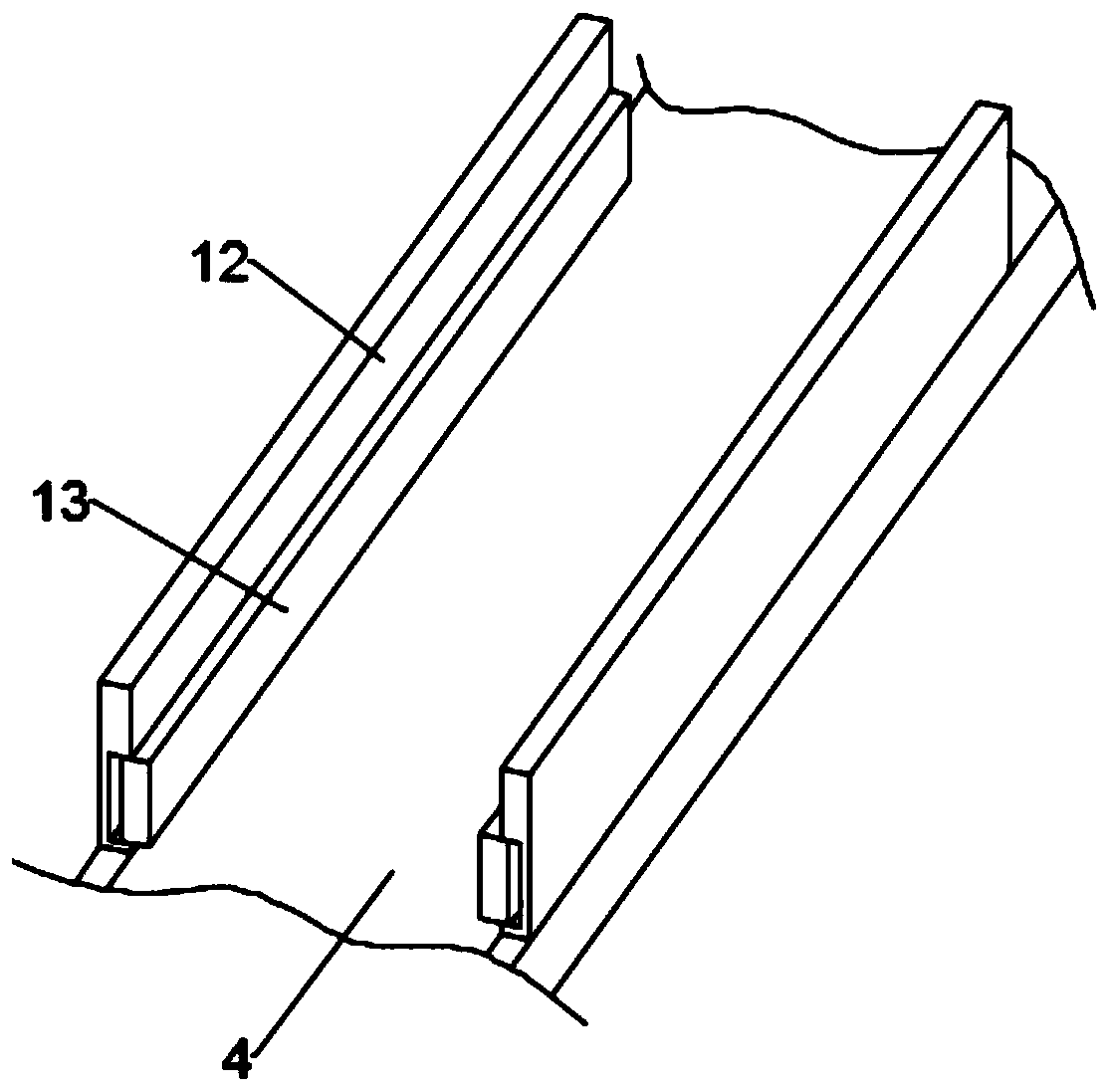

Embodiment 1

[0039] see Figure 1~6 In one embodiment provided by the present invention, an environmental protection construction waste treatment device includes a bottom plate 1, and the upper surface of the bottom plate 1 is provided with a transmission mechanism, a crushing box 15 and a dust box 36 in sequence from left to right; The transmission mechanism includes a wet material conveyor belt 2 and a dry material conveyor belt 3, the wet material conveyor belt 2 and the dry material conveyor belt 3 are respectively connected to the feeding conveyor belt 4, and the feeding conveyor belt 4 is connected to the crushing box 15, the wet material conveyor belt 2 passes through the drying box 5, and the drying box 5 is provided with a drying mechanism; the inside of the crushing box 15 is provided with a double crushing mechanism, and the bottom of the double crushing mechanism There is a screening mechanism; the crushing box 15 is connected to the dust collecting box 36 through a dust suctio...

Embodiment 2

[0055] see Figure 1~6 , In yet another embodiment provided by the present invention, an installation frame 37 is installed inside the dust collection box 36, and a dust collection bag 38 is provided in the installation frame 37; a suction fan is provided outside the dust collection box 36 39. The suction port of the suction fan 39 is provided with a connecting pipe to connect with the dust box 36.

[0056] In the process of crushing and screening materials, start the suction fan 39, and under the suction of the suction fan 39, the dust suction pipe 35 can absorb the flying dust generated in the crushing box 15 into the dust collection box 36, and use the collection The dust bag 38 absorbs it, which can ensure the cleanliness of the working environment and prevent the staff from absorbing the dust, which is not conducive to their health.

[0057] The electrical components appearing in this article are all connected with the external main controller and 220V mains electricity,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com