Intelligent identification method of material in soybean milk machine

An intelligent identification, soymilk machine technology, applied in beverage preparation devices, milk substitutes, household appliances, etc., can solve the problem that it is difficult to install cameras or scanning equipment in the soymilk machine, the user's requirements are high, and the intelligence of the soymilk machine cannot be reflected, etc. problems, to achieve the effect of simple and effective detection, prolonging motor life, and reducing overflow problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

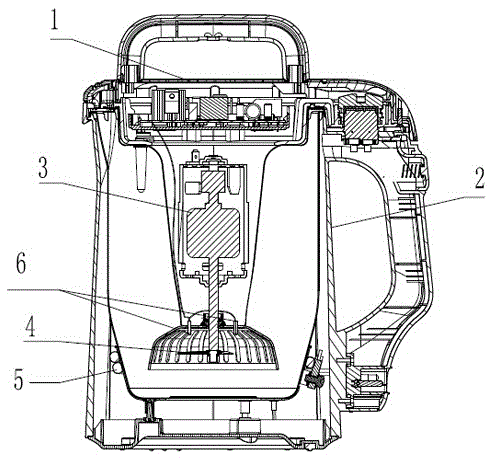

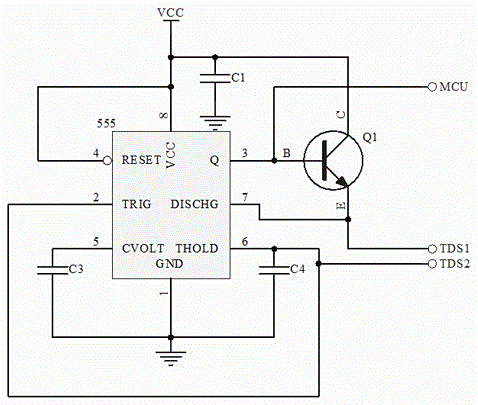

[0026] The present invention relates to a kind of soybean milk machine, such as figure 1 As shown, the soymilk machine includes a machine head 1 and a cup body 2, the machine head 1 is buckled on the cup body 2, the machine head 1 is provided with a motor 3 for crushing materials, and the motor 3 The front end extends into the cup body and is provided with a crushing tool 4, and the cup body 2 is provided with a heating device 5 for heating the materials in the cup body. The soymilk machine includes a control part, and the control part includes a main control chip MCU, and the main control chip MCU controls the motor 3 and the heating device 5 through a control circuit, and the soymilk machine also includes a device for detecting the water quality of the slurry in the cup. The water quality of the situation will measure the device 6, the main control chip MCU is connected to the water quality detection device 6 through the signal detection circuit, and the water quality detect...

Embodiment 2

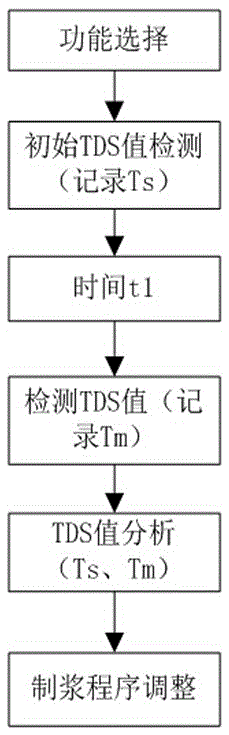

[0057] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that after the soymilk maker pulp program is started, the main control chip detects the water quality Ts of the slurry in the cup through the water quality detection device, and the main control chip detects the water quality Ts of the slurry in the cup. After the material is heated to temperature Q, the water quality Tm of the slurry is detected by the water quality detection device again, and the control chip analyzes and identifies the material according to the changes of Tm and Ts.

[0058] Since the measurement of solution conductivity is greatly affected by temperature, the ionization constant, ion velocity, and solubility of the electrolyte are all directly affected by temperature, so temperature directly affects the accuracy of solution conductivity measurement. When the temperature of the solution rises, the hydration of the particles weakens, the viscosity of the solution de...

Embodiment 3

[0068] Such as Figure 5 As shown, the difference between this embodiment and the above-mentioned embodiment 2 is that: before the main control chip detects the water quality Tm, the main control chip controls the motor to pre-shred the materials in the cup. That is, the identification and detection of material type and material quantity occurs after pre-crushing.

[0069] The initial water quality detection occurs after the selection function of the machine equipment is activated. Generally, there is no need to delay, and the detection can be started after the function is activated. Of course, the detection can also be started when the soymilk machine is powered on and the function is not selected. At this time, the material has not yet started. Crushing, the water has not started to be heated, the water temperature is relatively stable, and the soluble substances in the material have the least impact on the water quality.

[0070] The identification and detection of materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com