Atomizing method and device for preparing superfine near-spherical low-oxygen metal powder

A technology of metal powder and atomization equipment, which is applied in the field of atomization for preparing ultra-fine near spherical low-oxygen metal powder, can solve the problems of restricting the development of metal injection molding, inability to obtain ultra-fine powder, and increasing post-processing process, etc. Pre-crushing effect, fine particle size, increasing crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

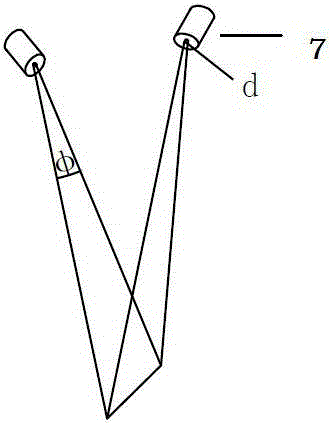

[0040] Such as Figure 1-Figure 2 As shown, the present embodiment prepares the atomization equipment for ultra-fine near spherical low-oxygen metal powder, including an atomizing leak bag 1, a high-pressure gas atomizing spray plate arranged on the bottom surface of the atomizing leak bag 1, and a high-pressure gas mist The high-pressure water atomizing spray disk 3 on the bottom surface of the spraying disk 2, the atomizing tube 4 arranged on the bottom surface of the high-pressure water atomizing spray disk 3, and the powder collecting tank 5 under the atomizing tube 4, wherein the high-pressure gas atomizing spray The disc 2, the high-pressure water atomizing spray plate 3 and the atomizing cylinder 4 are provided with a mutually communicating channel 6, an atomization area is formed in the channel 6, and the channel 6 is connected with a leak hole provided at the bottom of the atomization leak bag 1. The water level in the atomization cylinder 4 is controlled by a slurry p...

Embodiment 2

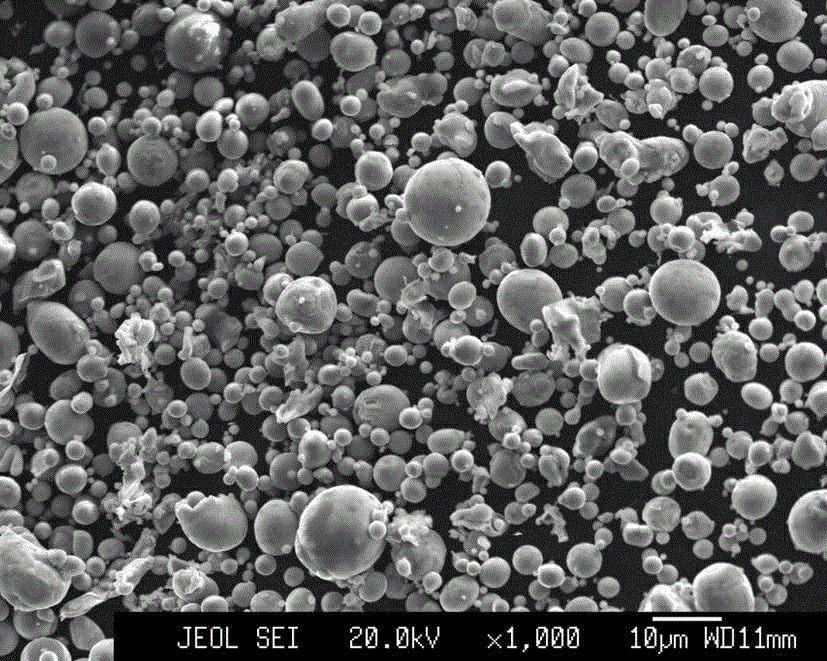

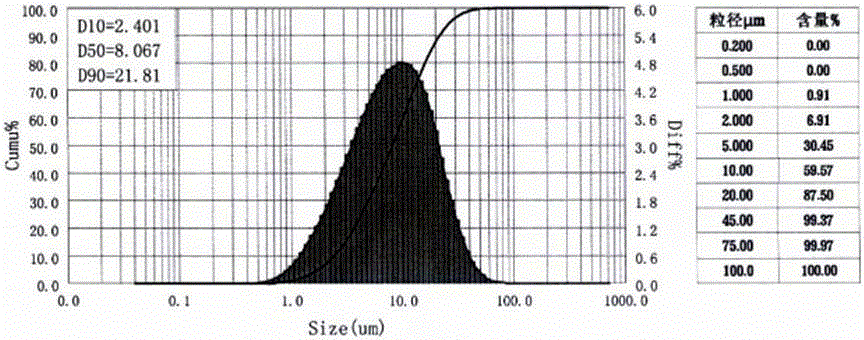

[0050] This embodiment uses the same equipment and method as the embodiment 1, but specifically, the embodiment takes the preparation of ultrafine, nearly spherical, low-oxygen 17-4PH stainless steel powder as an example for specific description.

[0051] Weigh 17-4PH ingredients according to weight percentage: Fe: 75.8%, Cr: 16%, Ni: 4%, Cu: 4%, Nb: 0.2%. The total weight is 100kg. It is added to the intermediate frequency melting furnace to heat and melt. When the alloy is melted, use a special composite deoxidizer to deoxidize and remove slag. When the temperature is measured at 1650℃, pour the molten metal into the atomization leak 1. The liquid flows into the atomization area through the leak hole at the bottom of the atomization leak bag 1. The flow rate of the metal liquid is controlled to 10kg / min, the inert atomization gas is nitrogen, the pressure is 0.4MPa, the flow rate is 2m3 / mim, and the annular high-pressure gas nozzle The annular slit width L of 21 is 2mm, and the...

Embodiment 3

[0054] In this embodiment, the atomization method for preparing ultrafine near-spherical low-oxygen metal powder includes the following steps:

[0055] S1 puts the metal raw materials into an intermediate frequency induction furnace for smelting, where the superheat of the metal is 100-200℃, and uses a composite deoxidizer to remove oxygen and slag

[0056] S2 pours the molten metal into the atomization leak of the atomization equipment. The molten metal flows into the mist at a flow rate of 8-20kg / min through the leak hole at the bottom of the leak under the action of gravity, high pressure air flow and negative pressure generated by high pressure water flow. Chemical zone; wherein the high-pressure gas is an inert gas, the pressure is 0.2-0.6MPa, the flow rate is 1-3m3 / min; the pressure of the high-pressure water is 80-120MPa, the flow rate of the high-pressure water is 35-75L / mim.

[0057] The metal liquid stream described in S3 becomes metal droplets under the atomization actio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com