Method for preparing monotectic alloy powder having shell-shaped composite constitution

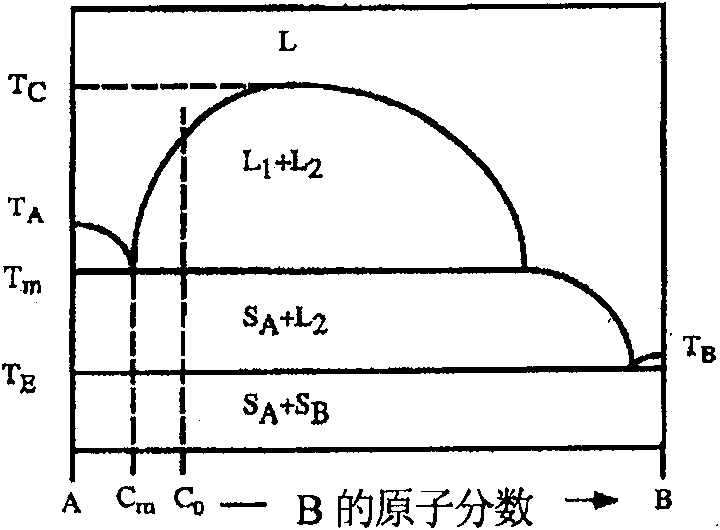

A technology of composite structure and alloy powder, which is applied in the field of atomization preparation of monomorphic alloy powder with shell-type composite structure, and can solve the problem that the cause of formation is not very clear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

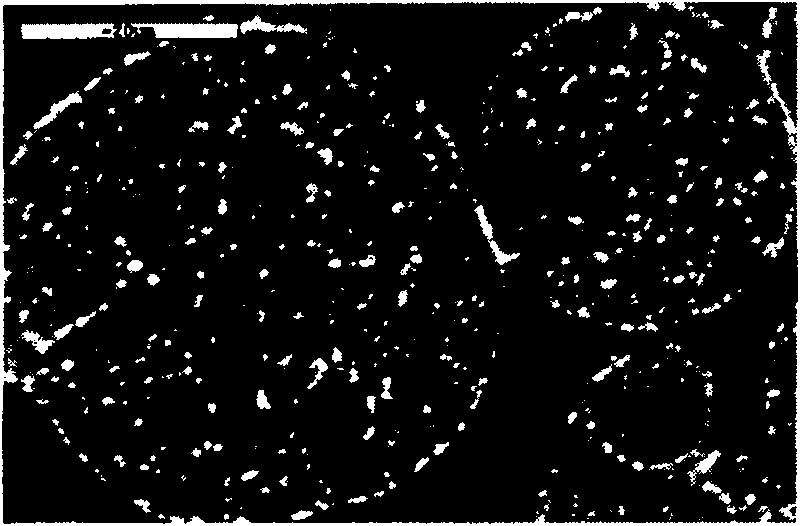

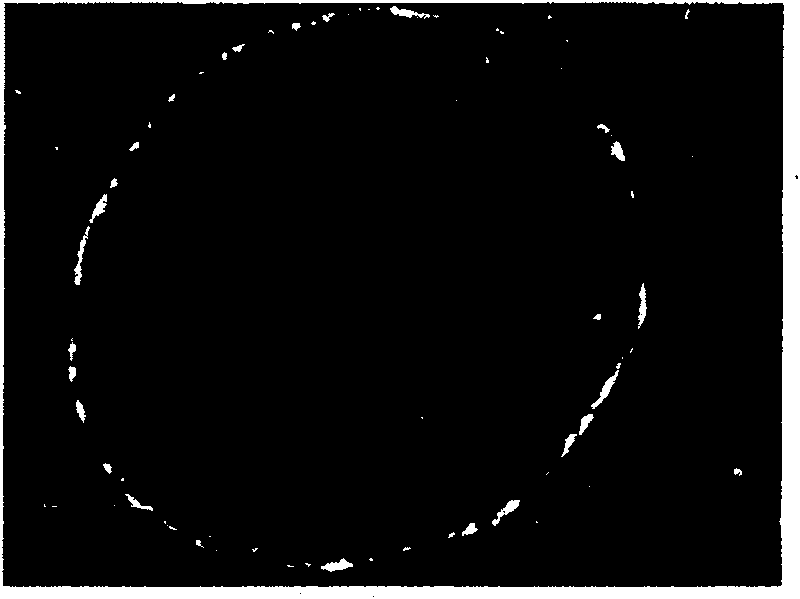

[0019] As shown in Figure 2(a), using a common gas atomization powder making device, for the Al-7wt%Pb alloy, argon is used as the atomizing gas, and the atomizing gas pressure is 40 atmospheres, and the surface-enriched Pb phase is prepared. Atomized powder with a particle size of 10-100 μm.

[0020] Its preparation process is as follows:

[0021] The monotectic alloy melt is smelted in a vacuum induction furnace, and a uniform melt is obtained after heat preservation at 1213K; the blocking rod placed and the melting crucible guide tube is pulled up, the melt flows out from the guide tube, and is atomized by the atomizing gas to become Small droplets, the atomized droplets are rapidly cooled and solidified under the action of the atomizing gas, and become powder.

Embodiment 2

[0023] As shown in Figure 2(b), using a common gas atomization powder making device, for the Al-15wt%Pb alloy, use ordinary industrial nitrogen (containing O 2 0.5-0.6Vol%) is the atomization gas, and other atomization parameters remain unchanged, and the atomized powder whose surface is enriched with Pb phase is prepared, and the particle size is 10-100 μm.

[0024] Its preparation process is as follows:

[0025] The monotectic alloy melt is smelted in a vacuum induction furnace, and a uniform melt is obtained after being kept warm at 1300K; the blocking rod placed and the melting crucible guide tube is pulled up, and the melt flows out from the guide tube and is atomized by the atomizing gas to become For small droplets, the atomizing gas pressure is 40 atmospheres; the atomized droplets are rapidly cooled and solidified under the action of the atomizing gas, and become powder.

Embodiment 3

[0027] As shown in Figure 2(c), using a common gas atomization powder making device, for the Al-30wt%Pb alloy, use ordinary industrial nitrogen (containing O 2 0.5-0.6Vol%) is the atomization gas, and other atomization parameters remain unchanged, and the atomized powder whose surface is enriched with Pb phase is prepared, and the particle size is 10-100 μm.

[0028] Its preparation process is as follows:

[0029] The monotectic alloy melt is smelted in a vacuum induction furnace, and a uniform melt is obtained after heat preservation at 1673K; the blocking rod placed and the melting crucible guide tube is pulled up, the melt flows out from the guide tube, and is atomized by the atomizing gas to become For small droplets, the atomizing gas pressure is 50 atmospheres; the atomized droplets are rapidly cooled and solidified under the action of the atomizing gas, and become powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com