Lithium ion battery module for electric forklift truck, and power supply box

A lithium-ion battery and electric forklift technology, applied in the field of lithium-ion batteries, can solve the problems of increased product cost, no box, hidden safety hazards, etc., and achieve the effect of increasing energy density, improving protection, and high protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

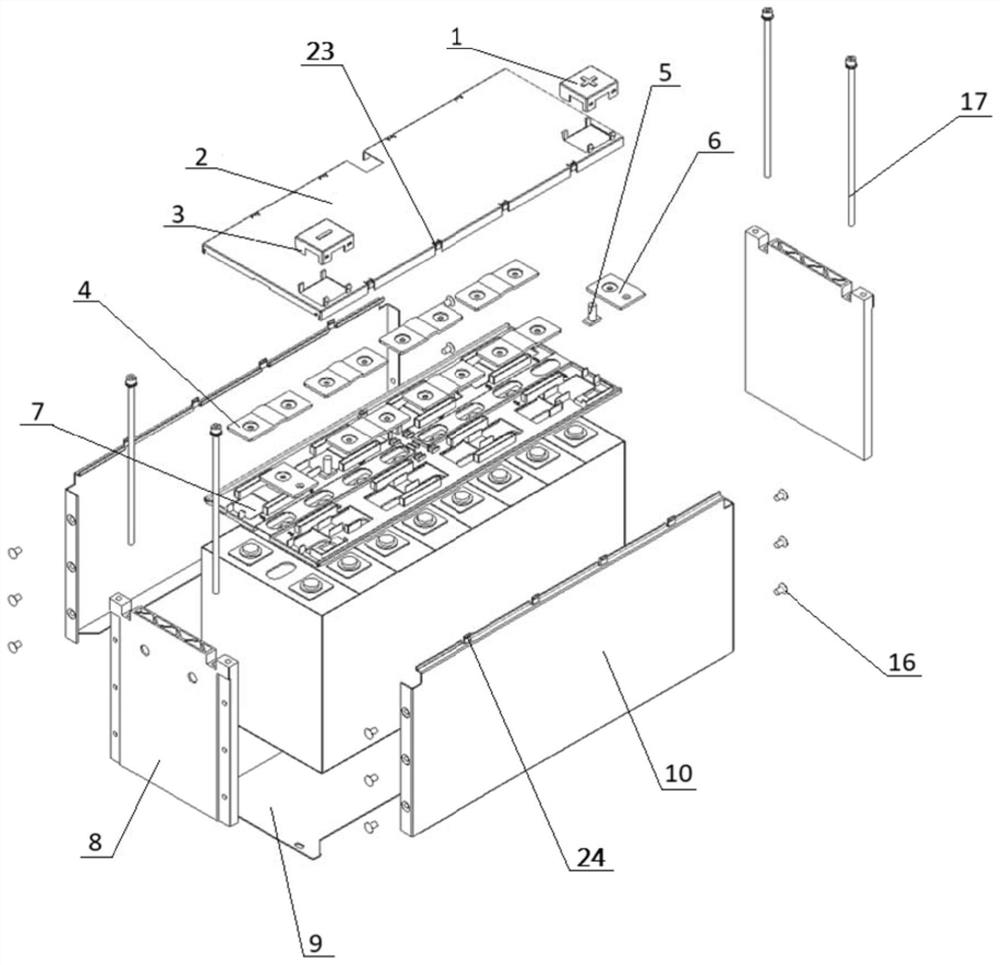

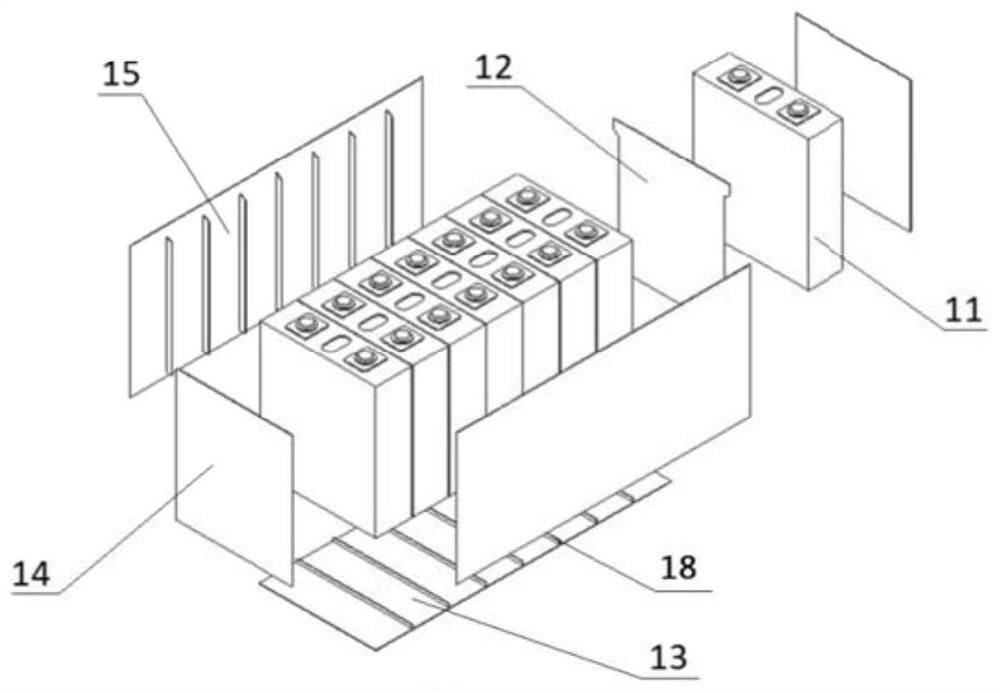

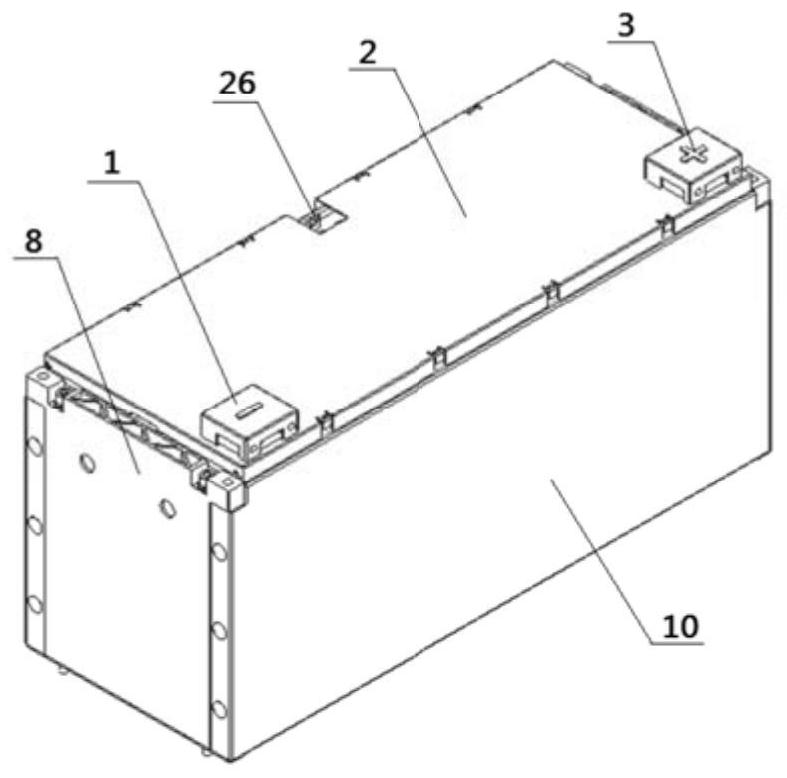

[0067] Such as Figure 1-3 As shown, the lithium-ion battery module for the electric forklift of the present invention includes a casing and a battery pack in the casing. The end face insulating plate 14, the side insulating plate 15, the bus bar bracket 7 on the top, and the battery cell 11 are square lithium iron phosphate batteries, which are grouped in 1 parallel and 8 strings. The bus bar bracket 7 is provided with the connecting row 4 between the cells 11 and the terminal connecting row 6 , and the shell includes an end plate 8 , a bottom plate 9 , a side plate 10 , and an upper outer cover 2 . The end plate 8 and the side plate 10 are connected by rivets 16, and the bottom plate 9 and the side plate 10 are connected by long dry screws. The end connection row 6 includes the total positive connection row 4 and the total negative connection row 4 with the same structure.

[0068] Such as Figure 6 As shown, the upper and lower edges of the side plate 10 are provided wit...

Embodiment 2

[0083] In order to achieve high structural strength, light weight, and high energy density of the lithium-ion battery module for electric forklifts without weakening the heat dissipation effect, this embodiment is designed on the basis of Embodiment 1: 1) Change the structural design of the end plate 8 and material; 2) Change the material of the plastic parts, that is, the upper outer cover 2, the total positive and negative insulation cover, the bus bar support 7, the bottom insulation plate 13, the end surface insulation plate 14, the side insulation plate 15; 3) Change the structure of the side plate 10 .

[0084] Such as Figure 12 As shown, the difference from Example 1 is that the end plate 8 is made of carbon fiber composite material, taking advantage of its excellent mechanical properties. The end plate 8 is the structure that accounts for the largest weight in the module except for the battery cell 11, and generally accounts for about 5% of the power battery pack, so...

Embodiment 3

[0091] Such as Figure 13-16 As shown, the lithium-ion power supply box for electric forklifts of the present invention includes a box body 34, a high-voltage box 35 and a BMS are arranged in the box body 34, and the lithium-ion battery module 38 for electric forklifts of embodiment 1 or 2 is also included. . There are 6 groups of battery modules 38, symmetrically placed on the left and right sides; the connection mode is 2 parallel and 3 series, the modules on the same side are connected in series, and the modules on both sides are connected in parallel.

[0092] The outer dimensions of the box body 34 can be 1127mm in length, 669mm in width and 686mm in height. The material is Q235a carbon steel, the thickness of the bottom is 176mm, the thickness of the surrounding plates is 16mm, and the thickness of the cover plate is 5mm. In order to increase the counterweight, there is a cavity at the bottom of the box body 34, which is filled with steel plates and compacted as a count...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com