Special-shaped sandwich fiber product sandwich guiding pultrusion device

A fiber product and sandwich technology, which is applied in the field of sandwich-guided pultrusion devices for special-shaped sandwich fiber products, which can solve the problems of poor support and routing of pultrusion forming devices, poor automation and continuous degree, and extrusion of fibers and surface mats Deformation and other problems, to achieve the effect of enhancing interlayer shear strength and surface toughness, improving surface finish, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

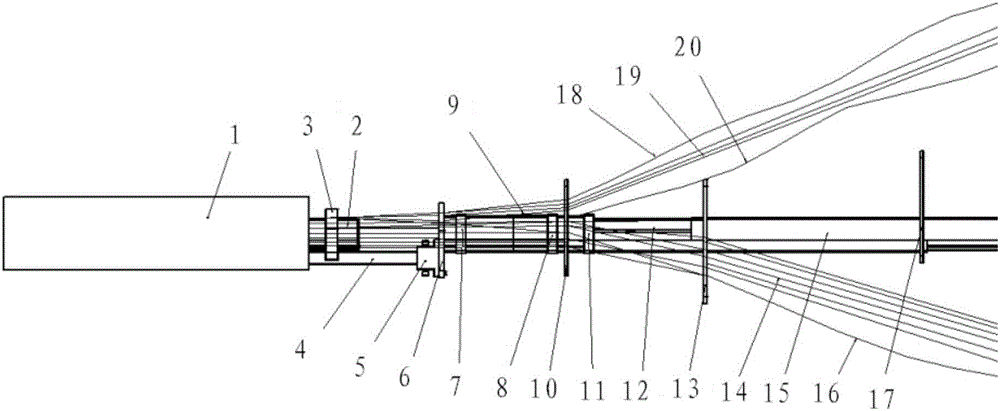

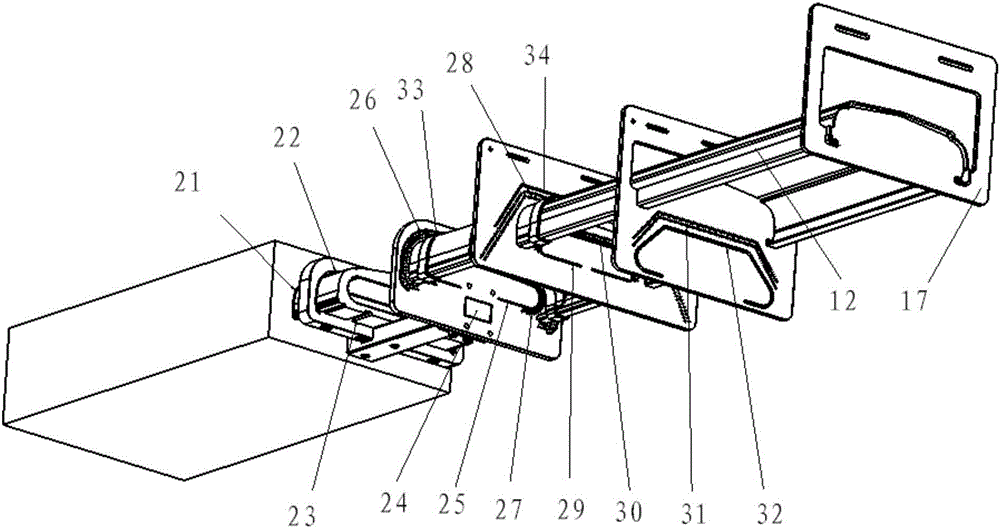

[0049] Such as figure 1 and 2 As shown, the core-guided pultrusion device for shaped sandwich fiber products in this embodiment includes: a pultrusion die 1 and a pre-forming module, a supporting and guiding module, and a connecting and positioning module.

[0050] The pultrusion die 1 comprises a forming die cavity 21 and a mold core. The forming die cavity 21 has a feed end and a discharge end. The die core passes through the entire forming die cavity 21 and extends to the outside of the feed end. The die core is at the feed end The external extension part is used as the preforming male mold 2; in the preforming module, the bottom surface of the preforming male mold 2 has a positioning groove 23, and the preforming ring 3 has a positioning hole, and the preforming male mold 2 and the preforming ring 3 are connected by bolts. The positioning groove 23 is fixed with the positioning hole.

[0051] The preforming module is arranged at the feeding end of the pultrusion die 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com