Ultraviolet (UV) light-curable polyurethane acrylic resin composite

A urethane acrylic and urethane acrylate technology, applied in the field of UV coatings, can solve the problems of poor UV paint adhesion, inability to form a good adhesion metal layer, protection and other problems, and achieve good sandability, excellent adhesion, and good continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

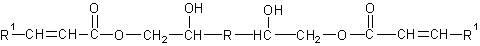

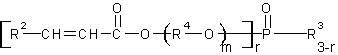

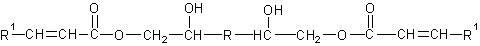

Method used

Image

Examples

Embodiment 1

[0051] The main components of the UV photocurable polyurethane acrylic resin composition of the present invention include the following raw materials in the weight ratio: 25 parts of polyurethane acrylate, 30 parts of epoxy acrylic resin, 2 parts of hydroxyethyl triacrylate phosphate, trimethylol 15 parts of propane triacrylate, 2.5 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone, 25 parts of talcum powder, and 0.5 parts of acrylate defoamer.

[0052] Among them: polyurethane acrylate is a mixture formed by polydiphenylmethane diisocyanate (MDI) and polyethyl acrylate, and its viscosity is 14000MPa at 25°C. The viscosity of epoxy acrylic resin at 25°C is 25000MPa·s, and the acid value of hydroxyethyl triacrylate phosphate is 300mgKOH / g.

[0053] After the above composition is formed into a film, the performance test is carried out, and the results are: hardness ≥ H, adhesion ≤ grade 1, yellowing resistance Δ E *<0.5, good sandability.

Embodiment 2

[0055] The main components of the UV photocurable polyurethane acrylic resin composition of the present invention include the following raw materials in the weight ratio: 30 parts of polyurethane acrylate, 30 parts of epoxy acrylic resin, 2.5 parts of ethylene methacrylate phosphate, methacrylic acid hydroxyl 5 parts of ethyl ester, 10 parts of isooctyl acrylate, 0.75 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1.5 parts of 1-hydroxycyclohexyl phenyl ketone, 20 parts of mica powder , 0.25 parts of leveling agent.

[0056] Among them: Polyurethane acrylate is a blend of polytoluene diisocyanate (TDI) and polyacrylic n-butyl ester, and its viscosity is 15000MPa at 25°C. The viscosity of epoxy acrylic resin at 25°C is 40000MPa·s, and the acid value of phosphoethylene methacrylate is 280mgKOH / g.

[0057] After the composition is formed into a film, a performance test is carried out, and the results are: hardness ≥ H, adhesion ≤ grade 1, yellowing resistance ΔE < 0.5,...

Embodiment 3

[0059] The main components of the UV photocurable polyurethane acrylic resin composition of the present invention include the following raw materials in the weight ratio: 30 parts of polyurethane acrylate, 35 parts of epoxy acrylic resin, 3 parts of methacrylate phosphate, trimethylolpropane triacrylic acid 15 parts of ester, 15 parts of 1,6-hexanediol diacrylate, 2 parts of 1-hydroxycyclohexyl phenyl ketone.

[0060] Among them: polyurethane acrylate is a mixture formed by poly(dicyclohexylmethane diisocyanate (HMDI)) and poly-n-butyl methacrylate, and its viscosity is 11000MPa·s at 25°C. The viscosity of epoxy acrylic resin is 35000MPa·s at 25°C. The acid value of polyethylene glycol methacrylate phosphate is 270 mgKOH / g.

[0061] When used, commercially available additives commonly used in this field are added to strengthen, toughen or improve smoothness and fluidity.

[0062] After the composition is formed into a film, a performance test is carried out, and the results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com