Molybdenum tailings acid soil conditioner and production process thereof

A technology of acidic soil and molybdenum tailings, applied in fertilizer mixture, fertilization device, application, etc., can solve the problems of low utilization, absorption and utilization, lack of medium and trace element mineral nutrition, etc., to reduce environmental pressure, reduce safety hazards, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

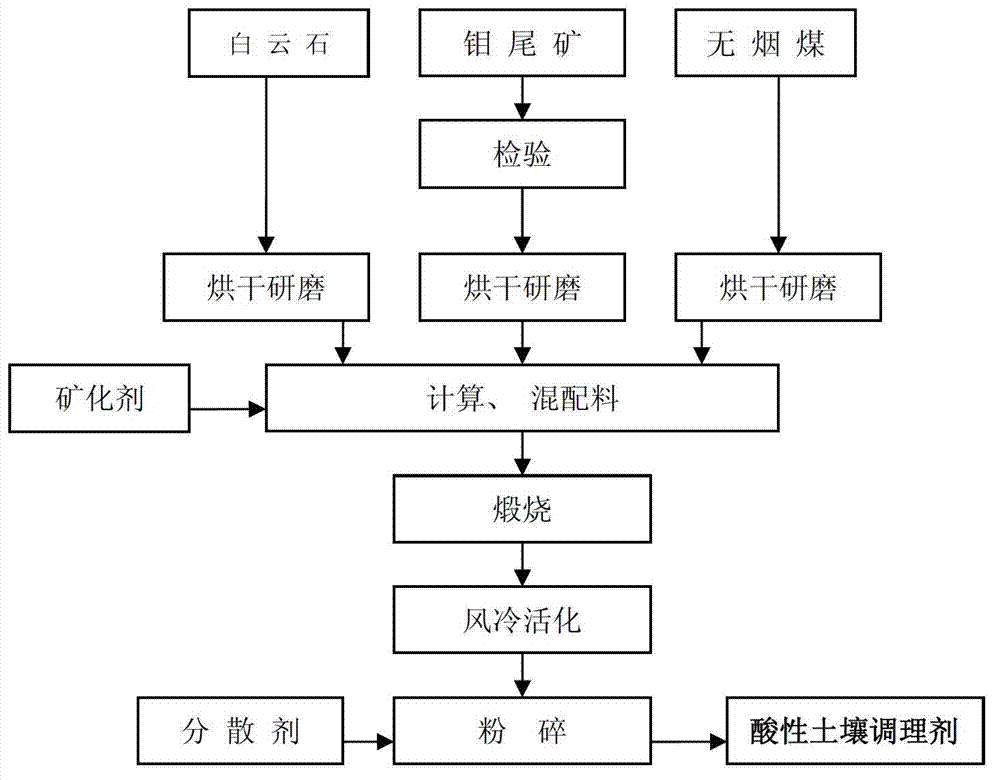

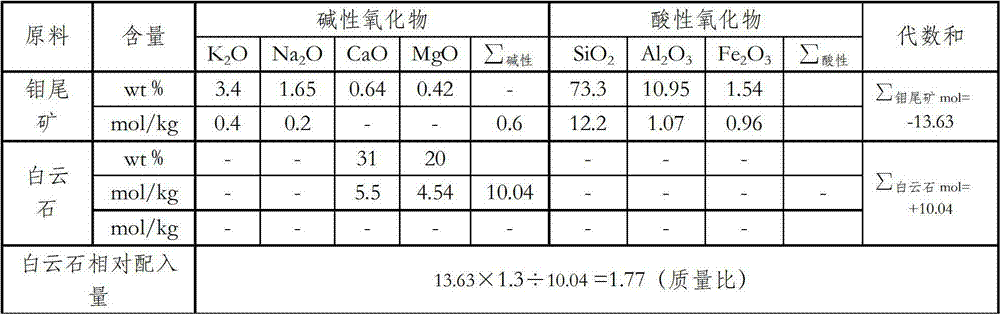

[0038] A molybdenum tailings acidic soil conditioner includes clinker, the clinker is prepared from molybdenum tailings, dolomite and anthracite as raw materials, and the selected molybdenum tailings, dolomite and anthracite raw materials comply with GB / T23349-2009 Specified molybdenum tailings; see Table 1 for the composition and calculation results of the tested raw materials:

[0039] Table 1: Raw material ratio calculation table

[0040]

[0041]

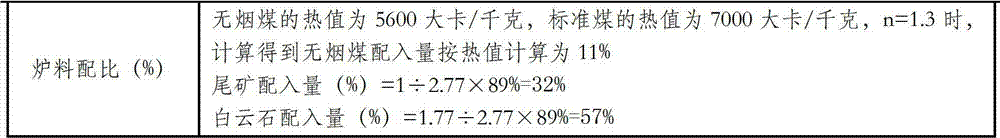

[0042] Among them, the molar ratio of basic oxide to acidic oxide is determined as n=1.3, and the calculated dosage of each component is 32% of molybdenum tailings, 57% of dolomite, and 11% of anthracite in terms of mass percentage, and the calculated anthracite Molecules in the assigned mass fractions are rounded to integers; produced according to the following steps:

[0043] Dry the raw materials separately and grind them in a ball mill. After passing through a 200-mesh sieve, mix the ground molybdenum tailings powder,...

Embodiment 2

[0045] A molybdenum tailings acidic soil conditioner includes clinker, the clinker is prepared from molybdenum tailings, dolomite and anthracite as raw materials, and the selected molybdenum tailings, dolomite and anthracite raw materials comply with GB / T23349-2009 Specified molybdenum tailings, of which, dolomite contains 31% calcium oxide and 20% magnesium oxide; molybdenum tailings contain 73.3% silicon dioxide, 10.95% aluminum oxide, 1.54% iron oxide, and 0.64% calcium oxide. %, magnesium oxide 0.42%, sodium oxide 1.65%, potassium oxide 3.40%; calorific value of anthracite 5200 kcal / kg, aluminum oxide 4.08%; according to the molar ratio of basic oxide to acidic oxide n=1.4 The amount of each component is calculated, and the molecules in the calculated mass fraction of anthracite are rounded to an integer, and in terms of mass percentage, they are respectively 31% of molybdenum tailings, 59% of dolomite, and 10% of anthracite, and according to The following steps produce: ...

Embodiment 3

[0048] A molybdenum tailings acidic soil conditioner includes clinker, the clinker is prepared from molybdenum tailings, dolomite and anthracite as raw materials, and the selected molybdenum tailings, dolomite and anthracite raw materials comply with GB / T23349-2009 Specified molybdenum tailings, of which, dolomite contains 31% calcium oxide and 20% magnesium oxide; molybdenum tailings contain 73.3% silicon dioxide, 10.95% aluminum oxide, 1.54% iron oxide, and 0.64% calcium oxide. %, magnesium oxide 0.42%, sodium oxide 1.65%, potassium oxide 3.40%; the calorific value of anthracite is 5600 kcal / kg, aluminum oxide 4.08%;

[0049] The amount of each component is calculated according to the molar ratio of basic oxides to acidic oxides n=1.2, and the molecules in the calculated mass fraction of anthracite are rounded to integers, and are molybdenum in mass percentages. Tailings 33.5%, dolomite 54.5%, anthracite 12%; and produce according to the following steps:

[0050] Dry the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com