Multi-stage homogenization heat treatment method for Zn-containing 6XXX series aluminum alloy

A technology for homogenizing heat treatment and aluminum alloys. It is applied in the field of multi-level homogenization heat treatment and heat treatment of 6XXX series aluminum alloys. , to achieve the effect of improving the organization, promoting uniform and fine precipitation, and excellent microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

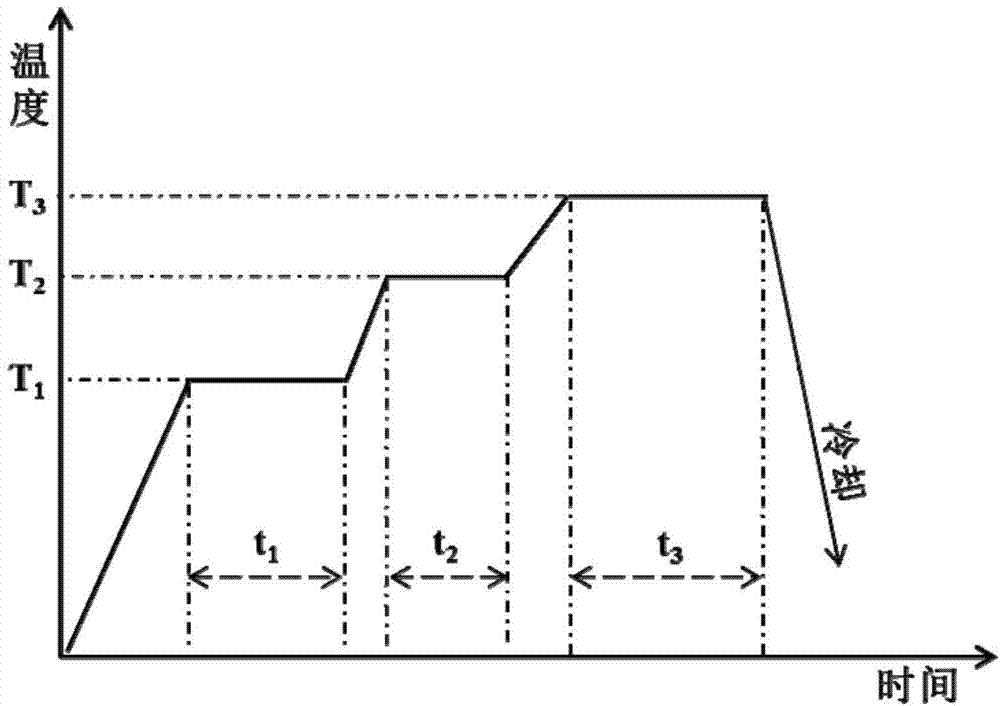

Method used

Image

Examples

Embodiment 1

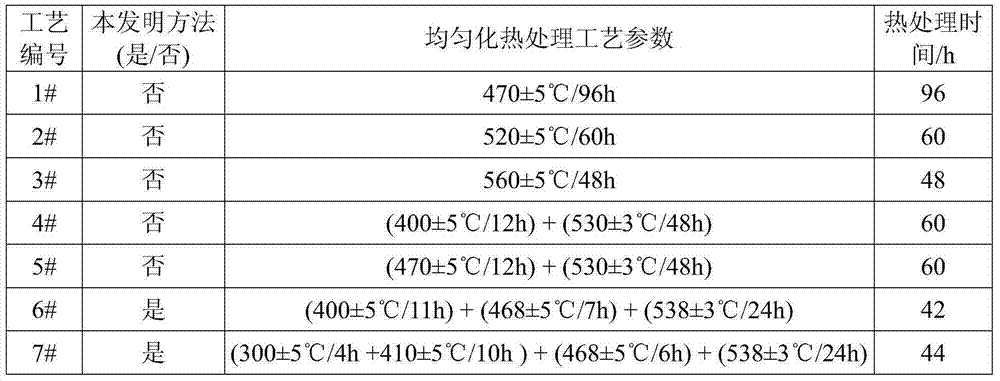

[0030] This embodiment takes alloy A as research object, contains the following components of weight percentage content in alloy A: Mg1.1%, Si1.1%, Zn0.9%, Mn0.2%, Zr0.12%, surplus is A1. Alloy A was produced into slabs with a thickness of 250 mm by semi-continuous casting under industrial conditions. The block samples were cut from the ingot, and the homogenization heat treatment tests of different schemes were carried out. The homogenization heat treatment system is shown in Table 1. Immediately after the homogenization treatment, water cooling is carried out to obtain the characteristic morphology of the structure reflecting the effect of the homogenization heat treatment of the alloy, so as to avoid the influence of a large amount of precipitation of the alloy during the slow cooling process and the second relative result analysis. The analysis test was carried out in accordance with the relevant standards, and the tissue analysis was carried out on the samples after diff...

Embodiment 2

[0037] This embodiment takes alloy B as the research object, containing the following components in weight percent in alloy B: Mg1.1%, Si1.1%, Zn1.8%, Mn0.2%, Zr0.12%, the balance is A1. Alloy B was made into a Φ230mm round ingot by semi-continuous casting under industrial conditions. The block samples were cut from the ingot, and the homogenization heat treatment tests of different schemes were carried out. The homogenization heat treatment system is shown in Table 3. Water cooling is carried out immediately after the homogenization treatment is completed. The analysis test was carried out in accordance with the relevant standards, and the tissue analysis was carried out on the samples after different homogenization treatments, and the results are shown in Table 4.

[0038] Table 3 Alloy B homogenization heat treatment process scheme

[0039]

[0040] Table 4 Microstructure analysis results of alloy B after different homogenization heat treatments

[0041]

[0042] ...

Embodiment 3

[0044] This embodiment takes alloy C as research object, contains the following components of weight percent content in alloy C: Mg1.1%, Si1.1%, Zn0.2%, Mn0.2%, Zr0.12%, balance is A1. Alloy C was made into 210 mm thick slabs by semi-continuous casting under industrial conditions. The block samples were cut from the ingot, and the homogenization heat treatment tests of different schemes were carried out. The homogenization heat treatment system is shown in Table 5. Water cooling is carried out immediately after the homogenization treatment is completed. The analysis test was carried out in accordance with the relevant standards, and the tissue analysis was carried out on the samples after different homogenization treatments, and the results are shown in Table 6.

[0045] Table 5 Alloy C homogenization heat treatment process scheme

[0046]

[0047] Table 6 Microstructure analysis results of alloy C after different homogenization heat treatments

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com