Two-stage forced solution treatment method for high strength deformed aluminum alloy

A deformed aluminum alloy and solution treatment technology, which is applied in the field of high-strength deformed aluminum alloy, can solve the problems of stress corrosion cracking resistance, spalling corrosion resistance, low fracture toughness, material performance degradation, and poor material reliability, etc., and achieve fatigue performance and Improvement of stress corrosion resistance, improvement of ultimate tensile strength and yield strength, and improvement of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

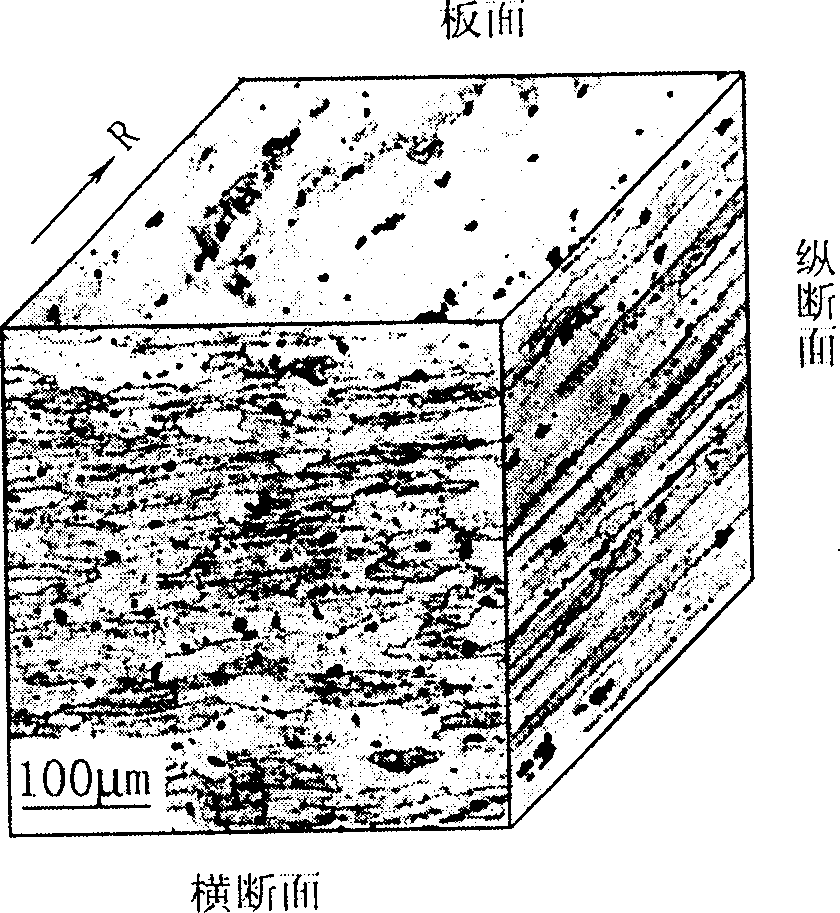

[0029] The spray-formed Al11Zn2.8Mg1.8Cu alloy adopts the method of the present invention to carry out two-stage forced solution treatment. The specific process is 450°C / 1h+475°C / 2h. The ultimate tensile strength of the alloy can reach 800-830MPa, and the elongation can reach 9 to 11%, while the fracture toughness and fatigue properties are effectively improved.

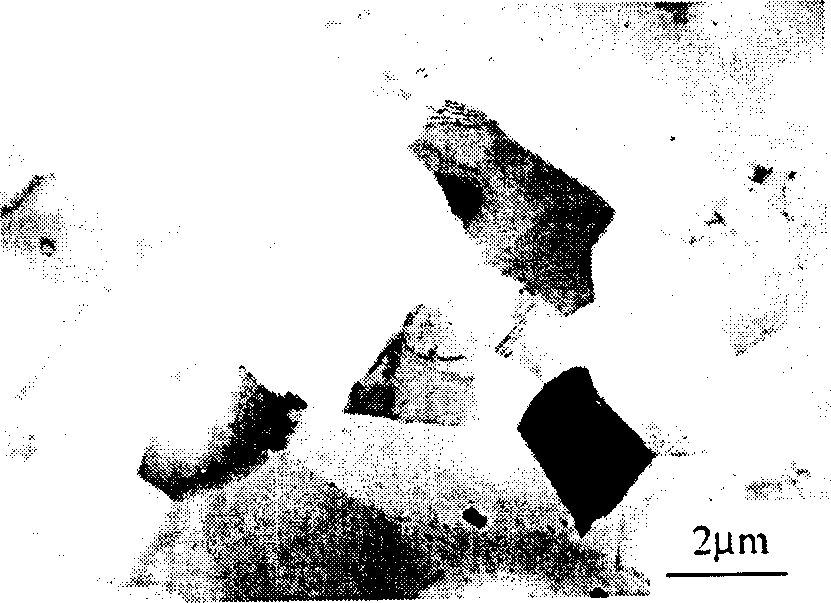

[0030] Such as figure 1 Shown is the TEM image of Al11Zn2.8Mg1.8Cu alloy after solution treatment at 450℃ / 1h+475℃ / 2h, from figure 1 Various types of MgZn that originally existed in large quantities on the intragranular grain boundaries can be found in 2 Phase, S phase and T phase are all dissolved back, achieving the purpose of solid solution treatment.

Embodiment 2

[0034] The B96 alloy alloy adopts the method of the present invention to carry out two-stage forced solution treatment. The specific process is 450°C / 1h+475°C / 2h. The ultimate tensile strength of the alloy can reach 700-720MPa, and the elongation can reach 6-8%. At the same time, the fracture toughness and fatigue properties are effectively improved.

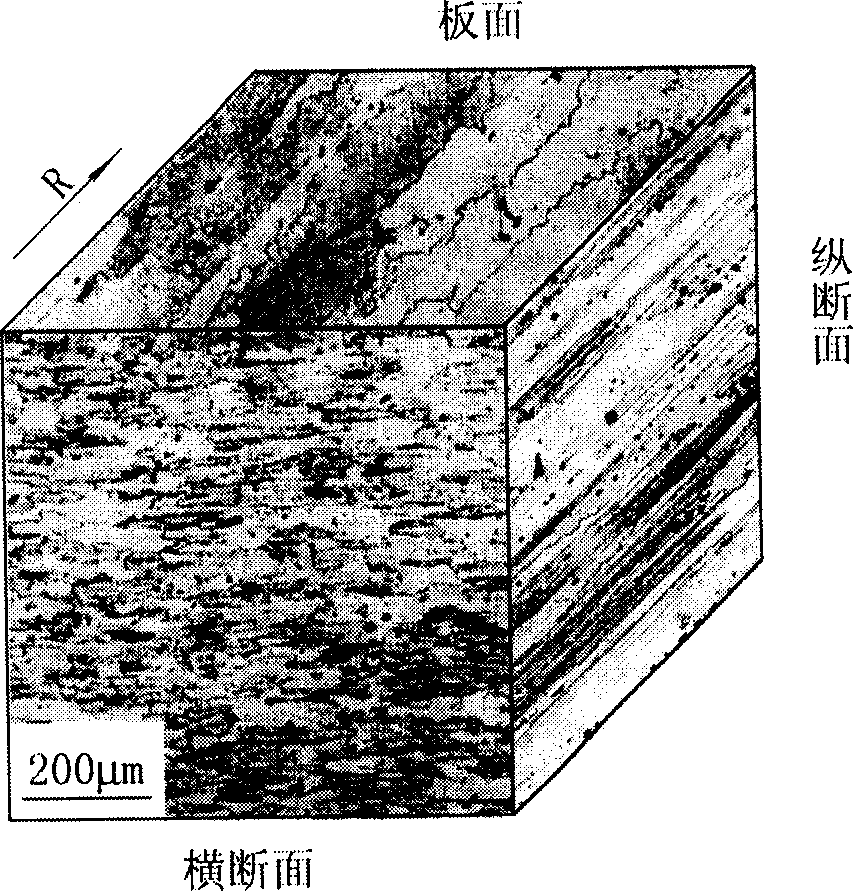

Embodiment 3

[0038] The 7055 alloy alloy adopts the method of the present invention to carry out two-stage forced solution treatment. The specific process is 440°C / 2h+480°C / 2h. The ultimate tensile strength of the alloy can reach 680-700MPa, and the elongation can reach 10-11%. At the same time, the fracture toughness and fatigue properties are effectively improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ultimate tensile strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com