Potassium decaborate sodium salt fertilizer and preparation method thereof

The technology of a potassium decaborate sodium salt and its production method is applied in the field of potassium decaborate sodium salt fertilizer and its production, which can solve the problems of not easy to dissolve and poor use effect, and achieve the effect of obvious fertilizer effect and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Potassium decaborate sodium salt fertilizer and its preparation

[0032] Potassium decaborate sodium salt fertilizer of the present invention is prepared as follows:

[0033] ①Use the patent number ZL200510130974.2 technology to prepare liquid sodium decaborate, take 100 parts by weight and store it in a reactor, keeping a high temperature above 150°C.

[0034] ②Add 85 parts by weight of water to the reaction kettle, then pour 40 parts by weight of potassium hydroxide into the reaction kettle, slowly add 80 parts by weight of boric acid, stir while adding, heat to above 100°C, and keep the temperature for 50 minutes until complete reaction .

[0035] reaction

[0036] KOH+H 3 BO 3 ——→KB 5 o 8 ·5H 2 O+H 2 O↑

[0037] ③ Add 100 parts by weight of sodium decaborate to the above product, adjust the pressure to above 8 Pa, and react at a temperature of 160° C. for 3 hours.

[0038] Na 2 B 10 o 16 + KB 5 o 8 --→Na 2 K 2 B 10 o 17 10H 2 o

[00...

Embodiment 2

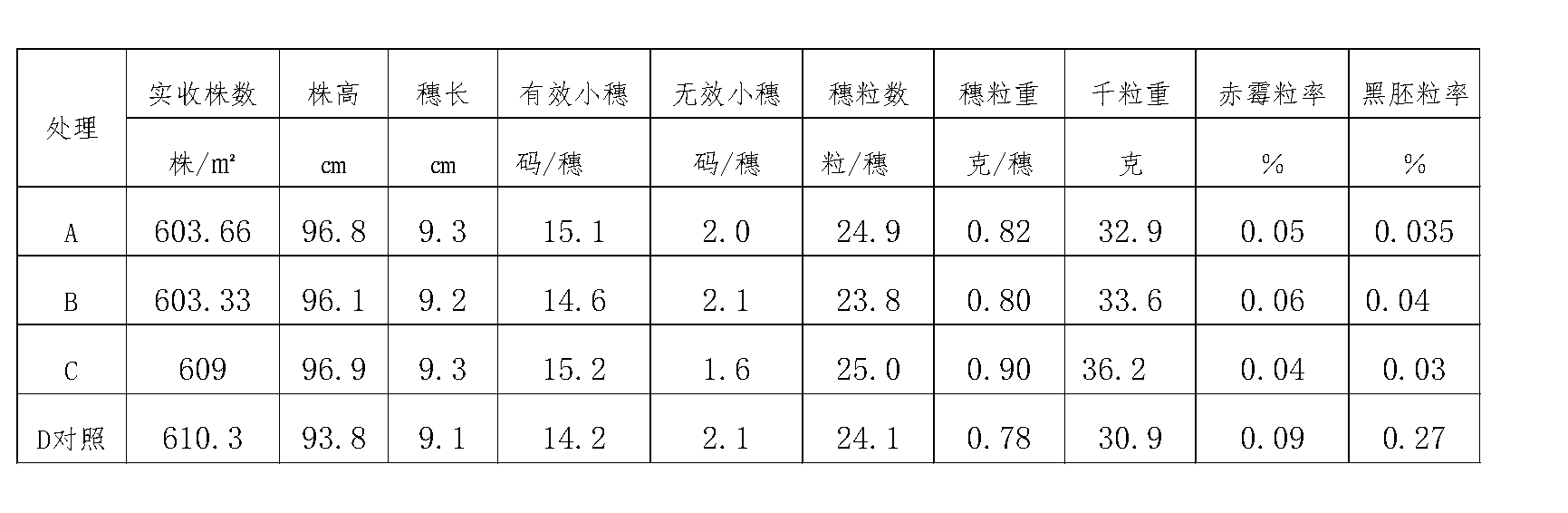

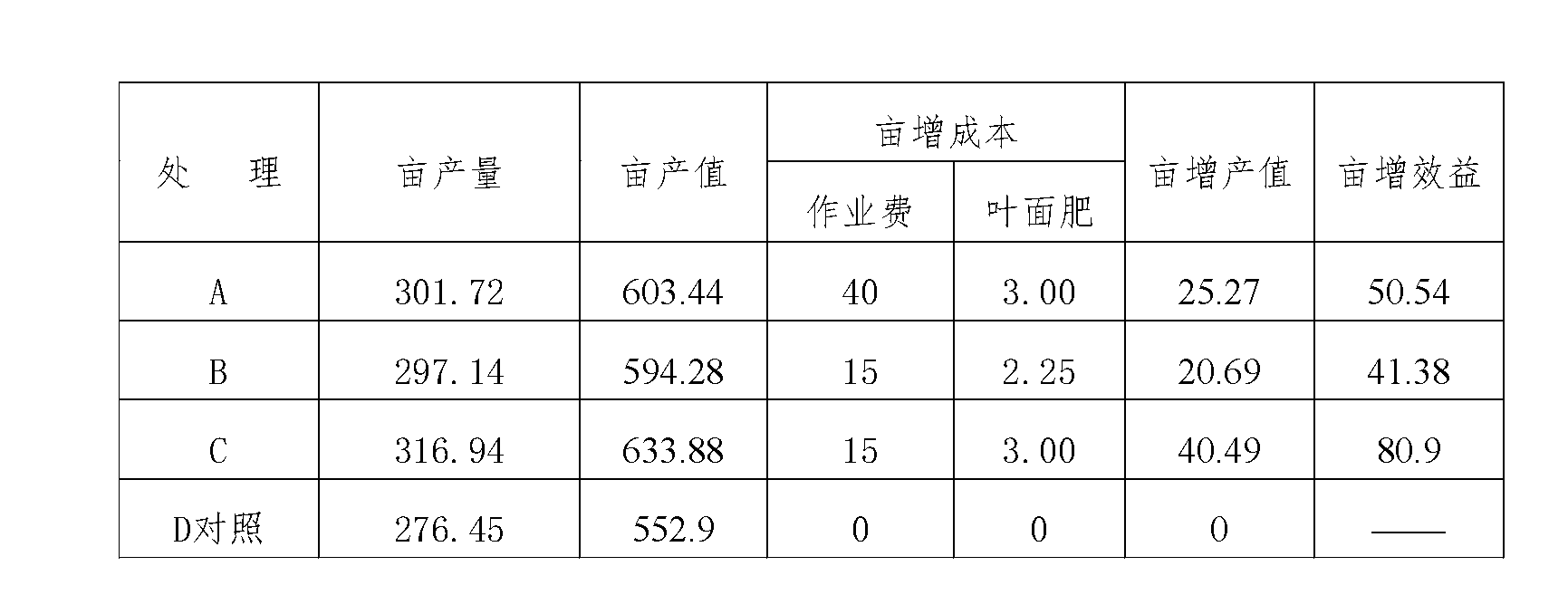

[0043] Example 2 Experimental Effect of Potassium Decaborate Sodium Salt on Wheat Fields

[0044] Potassium decaborate sodium salt contains boron ≥ 20%, potassium ≥ 18%, developed by Anhui Nongwang Agricultural Science and Technology Development Co., Ltd. In order to test the application effect of this product on wheat, the following test is specially done, and the test results are summarized as follows:

[0045] 1. Basic situation of the test site

[0046] The test site is located in the No. 9 field of the second resident group of the first management area of Yinlonghe Farm, Heilongjiang Province. The black soil layer is 20-35 cm, and the fertility is medium. Once, lightly rake twice.

[0047] 2. Test materials and methods

[0048] 2.1. Test materials

[0049] Wheat varieties tested: Kenda 16,

[0050] Fertilizer products to be tested: sodium potassium decaborate, potassium decaborate, sodium decaborate

[0051] 2.2. Test treatment

[0052] The experiment consisted of...

Embodiment 3

[0078] Example 3 Making Grinding Fluid Using Potassium Decaborate Sodium Salt

[0079] With 10 parts by weight of potassium decaborate sodium salt, 10 parts by weight of ethyl acetate, 30 parts by weight of machine oil, 5 parts by weight of sodium sulfonate, 3 parts by weight of organic silicon, 22 parts by weight of triethanolamine, 10 parts by weight of oleic acid, 10 parts by weight of The parts by weight of deionized water are dissolved and mixed, and then ground evenly with a colloid mill to be used as a grinding fluid.

[0080] Use: Use injector to inject grinding fluid into the grinding surface during mechanical processing, and the grinding agent can lubricate, cool, clean and prevent rust.

[0081] Use effect: the cooling process of the workpiece is shortened by 30%, the degree of lubrication is increased by 25%, the residual rate of debris is reduced by 33%, the brightness is increased by about 40%, and the anti-rust ability is enhanced, and the area of rust spots i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com