A high-performance brazing method for ni3al-based single crystal alloys

A brazing method and single-crystal-based technology, which is applied in welding equipment, welding medium, metal processing equipment, etc., can solve problems such as strict weld gap control requirements, impact on structure and performance, and poor process applicability, and achieve interface The effect of good organization, good combination, and mechanical properties up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0028] The brazing method of present embodiment IC21 single crystal alloy comprises the steps:

[0029] Step 1: Clean up before welding

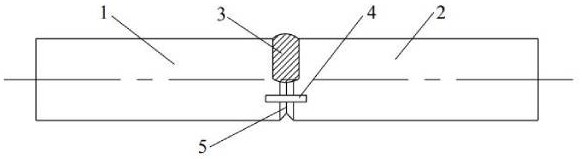

[0030] IC21 single crystal alloy (solution heat treatment state) is machined to remove the oxide skin on the surface, and processed into such as figure 1 The dimensions shown are (Φ15×33) mm cylindrical IC21 single crystal alloy base materials 1 and 2 to be welded; ultrasonic cleaning for 15 minutes before assembly removes oil and other impurities on the surface of IC21 single crystal alloy base materials 1 and 2 to be welded.

[0031] Step 2: Assembly positioning

[0032] On the fixture, press the figure 1 As shown, two IC21 single crystal alloy base metals 1 and 2 with a size of (Φ15×33) mm are butt-jointed and assembled along the axial direction, and the brazing gap of the joint 5 to be welded is controlled to be 50 μm. Fix the high-temperature alloy sheets 4 (3 uniformly distributed along the circumference at intervals of 120°) on the...

Embodiment 2

[0044]The brazing method of present embodiment IC21 single crystal alloy comprises the steps:

[0045] Step 1: Clean up before welding

[0046] IC21 single crystal alloy (solution heat treatment state) is machined to remove the oxide skin on the surface, and processed into such as figure 1 The shown size is (Φ15×33) mm cylindrical IC21 single crystal alloy base materials 1 and 2 to be welded; ultrasonic cleaning for 20 minutes before assembly removes oil and other impurities on the surface of IC21 single crystal alloy base materials 1 and 2 to be welded.

[0047] Step 2: Assembly positioning

[0048] On the fixture, press the figure 1 As shown, two IC21 single crystal alloy base metals 1 and 2 with a size of (Φ15×33) mm are butted together along the axial direction to be welded, and the brazing gap of the joint 5 to be welded is controlled to be 100 μm. Fix the high-temperature alloy sheets 4 (3 uniformly distributed along the circumference at intervals of 120°) on the ends...

Embodiment 3

[0060] The brazing method of present embodiment IC21 single crystal alloy comprises the steps:

[0061] Step 1: Clean up before welding

[0062] IC21 single crystal alloy (solution heat treatment state) is machined to remove the oxide skin on the surface, and processed into such as figure 1 The shown size is (Φ15×33) mm cylindrical IC21 single crystal alloy base materials 1 and 2 to be welded; ultrasonic cleaning for 20 minutes before assembly removes oil and other impurities on the surface of IC21 single crystal alloy base materials 1 and 2 to be welded.

[0063] Step 2: Assembly positioning

[0064] On the fixture, press the figure 1 As shown, two IC21 single crystal alloy base metals 1 and 2 with a size of (Φ15×33) mm are butted together along the axial direction to be welded, and the brazing gap of the joint 5 to be welded is controlled to be 200 μm. Fix the high-temperature alloy sheets 4 (3 uniformly distributed along the circumference at intervals of 120°) on the end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com