Tungsten-copper module for high thermal load parts of fusion device and preparation method thereof

A tungsten-copper, high-heat technology, applied in the field of tungsten-copper modules and their preparation, to achieve the effects of strong reliability, high efficiency and low cost

Active Publication Date: 2016-08-10

SOUTHWESTERN INST OF PHYSICS

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The object of the present invention is to provide a kind of tungsten-copper module and preparation method thereof for high thermal load parts of fusion device, which can solve the fast connection problem of tungsten-copper composite

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

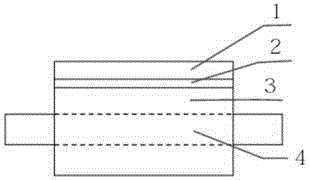

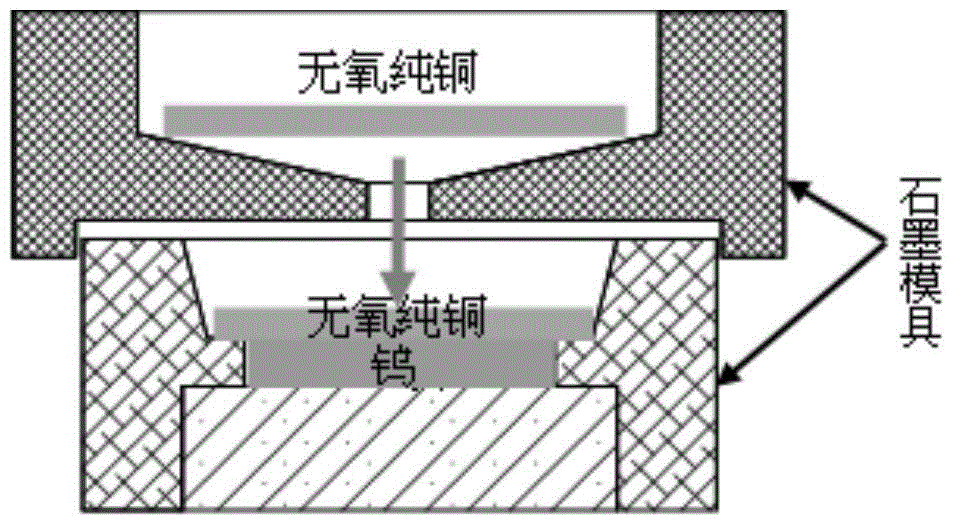

The invention relates to the technical field of connection of heterogeneous materials and particularly relates to a tungsten copper module for a high thermal load part of a fusion device as well as a preparation method thereof. The method comprises the following steps: 1) selecting tungsten, anaerobic pure copper and a chromium zirconium copper alloy heat sink material in appropriate size; 2.1) pre-treating surfaces of tungsten and anaerobic pure copper; 2.2) carrying out vacuum-casting on the anaerobic pure copper on the surface of tungsten; 3.1) pre-treating the surface of the anaerobic pure copper in a tungsten / anaerobic pure copper block and a to-be-welded face of a chromium zirconium copper alloy; 3.2) welding the tungsten / anaerobic pure copper block and the chromium zirconium copper alloy in a vacuum hot pressed furnace; and 3.3) machining a welded tungsten / anaerobic pure copper / chromium zirconium copper alloy compound block to form the required tungsten copper module. The preparation method of the tungsten copper module is low in cost, high in efficiency and high in reliability and the tungsten copper module can bear a steady state thermal load which is greater than 5MW / m<2>.

Description

technical field The invention belongs to the technical field of connection of heterogeneous materials, and in particular relates to a tungsten-copper module used for high thermal load parts of a fusion device and a preparation method thereof. Background technique Tungsten is widely considered to be the most promising nuclear fusion device due to its advantages such as high melting point, excellent thermal conductivity, low sputtering yield and high self-sputtering threshold, low vapor pressure and low tritium retention performance. body material. Tungsten is connected with heat sink material copper alloy or structural material to make plasma-facing parts, which can be applied to the first wall and divertor positions of fusion devices. The biggest problem with the connection between tungsten and heat sink material copper is the large difference in thermal expansion coefficient and modulus of elasticity between tungsten and copper. The thermal expansion coefficient of tungs...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B32B15/01C22C9/00B22D19/16B23P15/00

CPCB22D19/16B32B15/01B32B15/20B32B38/162B32B38/18B32B2250/03B32B2307/306C22C9/00

Inventor 练友运刘翔封范

Owner SOUTHWESTERN INST OF PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com