Copper-based and aluminum-based alloy lubricating, antifriction and wear-reducing material obtained by sintering and cladding method and preparation method thereof

An aluminum-based alloy and copper alloy technology, applied in metal material coating process, mechanical equipment, manufacturing tools, etc., can solve the problems of low material strength and fatigue resistance, poor friction and wear reduction effect, and high metallographic porosity , to achieve the effect of good density, low porosity and good shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

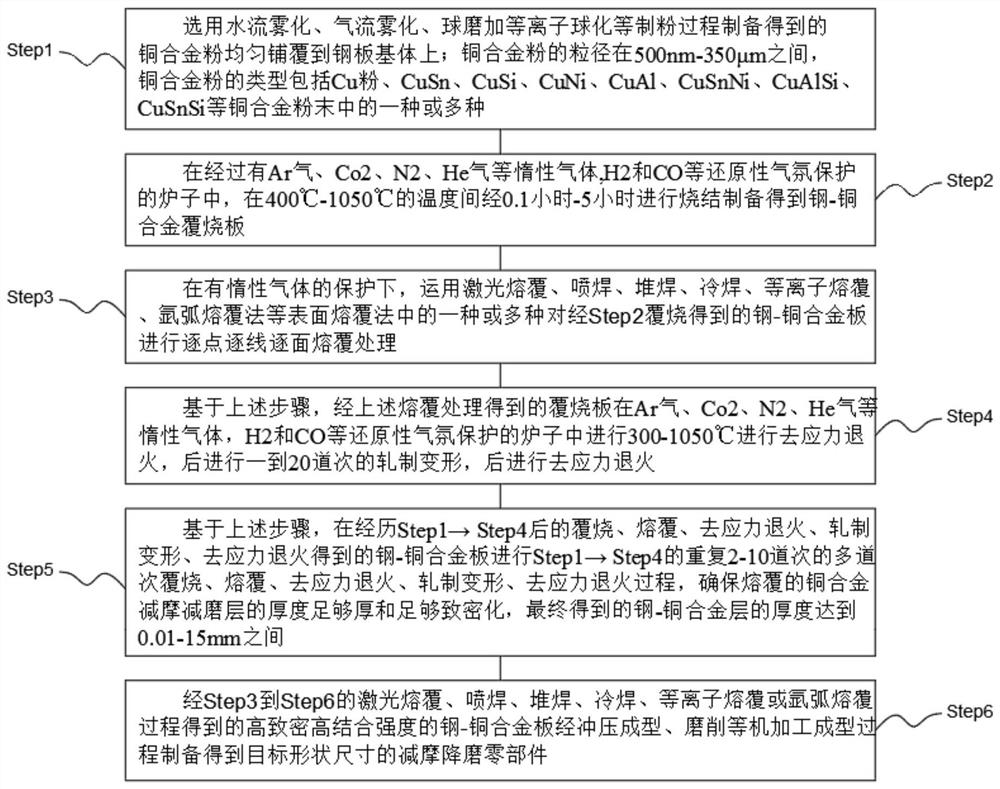

[0041] see Figure 1-3 Shown: the present invention is a copper-based and aluminum-based alloy lubricating anti-friction and anti-wear material obtained by sintering cladding method. Low-carbon steel, stainless steel plate, low-alloy steel and other plates are selected as the base material, and the water atomization is used to , Copper alloy powder or aluminum alloy powder prepared by air atomization or plasma spheroidization after ball milling is used as alloyed powder for anti-friction and anti-wear layer;

[0042] A method for preparing a steel-copper alloy anti-friction and anti-wear material, comprising the following steps:

[0043] Step1: The copper alloy powder prepared by water atomization, air atomization, ball milling plus plasma spheroidization and other pulverizing processes is evenly spread on the steel plate substrate; the particle size of the copper alloy powder is between 500nm-350μm, and the copper alloy powder The type includes one or more of Cu powder, CuSn...

Embodiment 2

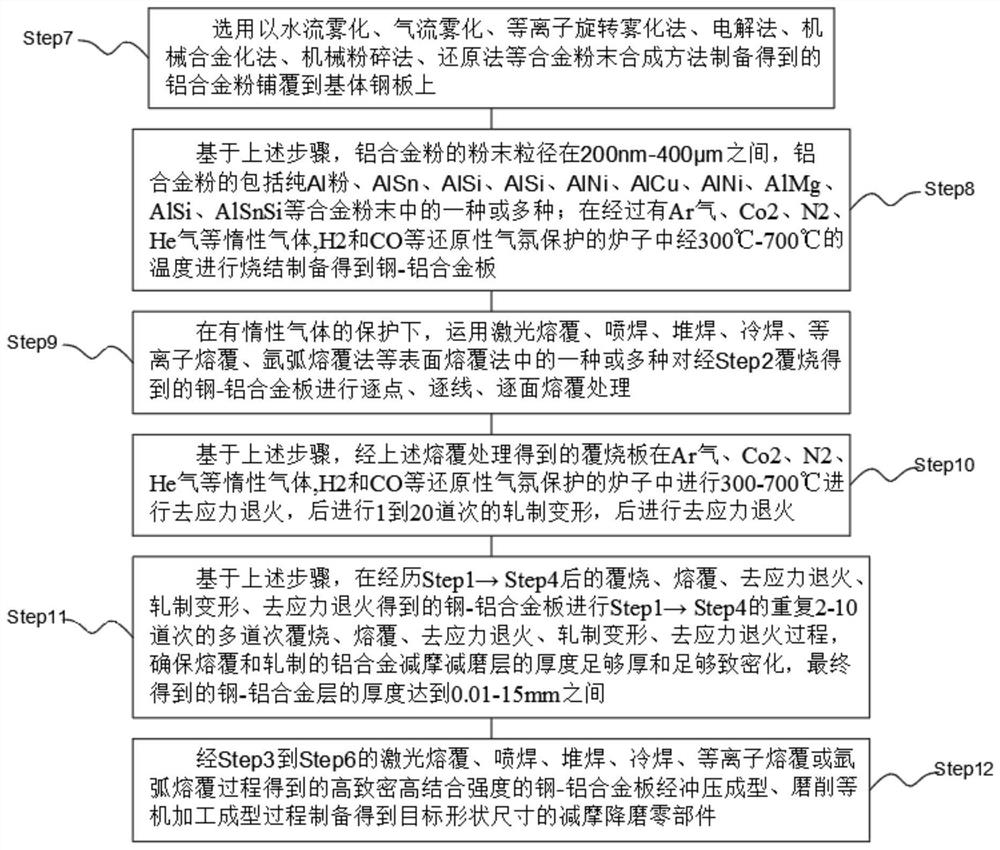

[0067] A method for preparing a copper-based and aluminum-based alloy lubricating anti-friction and anti-wear material obtained by a sintering cladding method, comprising the following steps:

[0068] Step 1: Select copper alloy copper powder and aluminum alloy powder atomized by water flow or air atomization to spread on the base steel plate, and obtain a steel-copper alloy plate after initial sintering in an atmosphere protected by inert gas and reducing gas or steel-aluminum alloy plate;

[0069] Step 2: Use a method of laser cladding, spray welding, surfacing welding, cold welding, plasma cladding, and argon arc cladding to process the steel-copper alloy plate or steel-aluminum alloy plate obtained in step 1 one by one. Line by point cladding;

[0070] Step 3: After step 2 laser cladding, spray welding, surfacing welding, cold welding, plasma cladding or argon arc cladding, the steel-copper alloy or steel-aluminum alloy plate is subjected to cold rolling→tempering→cold ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com