Purifying method for ultra-pure aluminum

A purification method and pure aluminum technology, applied in the field of ultra-high-purity aluminum purification, can solve the problems of unstable quality, low purification efficiency, and no qualified products can be produced, so as to reduce purification costs, improve purification efficiency, and increase safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

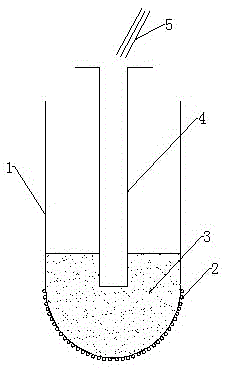

Image

Examples

Embodiment 1

[0022] The method for purifying ultra-high-purity aluminum of the present embodiment, the specific steps of the method are as follows:

[0023] (1) Inject 400 kg of molten aluminum with a purity of 4N6 into the cast iron crucible, and heat it through the heating wire on the outer wall of the cast iron crucible to keep the molten aluminum at 700°C;

[0024] (2) Extend the seed crystal above the cast iron crucible into 3cm below the liquid level of the aluminum liquid, and pass the cooling gas at 0°C into the other end of the seed crystal to cool and crystallize the aluminum liquid, and keep the ventilation flow at 1L / min; At the same time, make the seed crystal rotate spirally in the cast iron crucible, and make the molten aluminum rotate in the cast iron crucible, the initial rotation speed is 100r / min, then gradually slow down, and finally the rotation speed is reduced to 70r / min;

[0025] (3) After the crystallization, the seed crystal with the crystal ingot was pulled out, ...

Embodiment 2

[0027] The method for purifying ultra-high-purity aluminum of the present embodiment, the specific steps of the method are as follows:

[0028] (1) Inject 400 kg of molten aluminum with a purity of 4N6 into the cast iron crucible, and heat it through the heating wire on the outer wall of the cast iron crucible to keep the molten aluminum at 690°C;

[0029] (2) Extend the seed crystal above the cast iron crucible into 2.5cm below the liquid level of the aluminum liquid, and pass the cooling gas of 20°C into the other end of the seed crystal to cool and crystallize the aluminum liquid, and keep the ventilation flow at 3L / min ; At the same time, make the seed crystal rotate spirally in the cast iron crucible, and make the molten aluminum rotate in the cast iron crucible, the initial rotation speed is 90r / min, then gradually slow down, and finally the rotation speed is reduced to 60r / min;

[0030] (3) After the crystallization, the seed crystal with the crystal ingot was pulled ou...

Embodiment 3

[0032] The method for purifying ultra-high-purity aluminum of the present embodiment, the specific steps of the method are as follows:

[0033] (1) Inject 400 kg of molten aluminum with a purity of 4N6 into the cast iron crucible, and heat it through the heating wire on the outer wall of the cast iron crucible to keep the molten aluminum at 680°C;

[0034] (2) Extend the seed crystal above the cast iron crucible into 2cm below the liquid level of the aluminum liquid, and pass the cooling gas of 10°C into the other end of the seed crystal to cool and crystallize the aluminum liquid, and keep the ventilation flow at 2L / min; At the same time, make the seed crystal rotate spirally in the cast iron crucible, and make the molten aluminum rotate in the cast iron crucible, the initial rotation speed is 80r / min, then gradually slow down, and finally the rotation speed is reduced to 60r / min;

[0035] (3) After the crystallization, the seed crystal with the crystal ingot was pulled out, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com