Method for preparing nickel-based catalyst precursor

A technology of nickel-based catalysts and substances, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as high precipitation temperature, affecting nickel activity level, and reducing the utilization rate of active metals. Achieve a uniform precipitation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

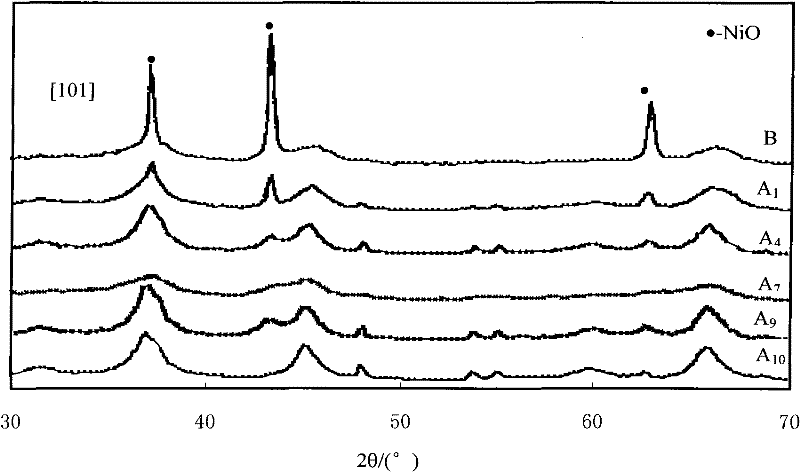

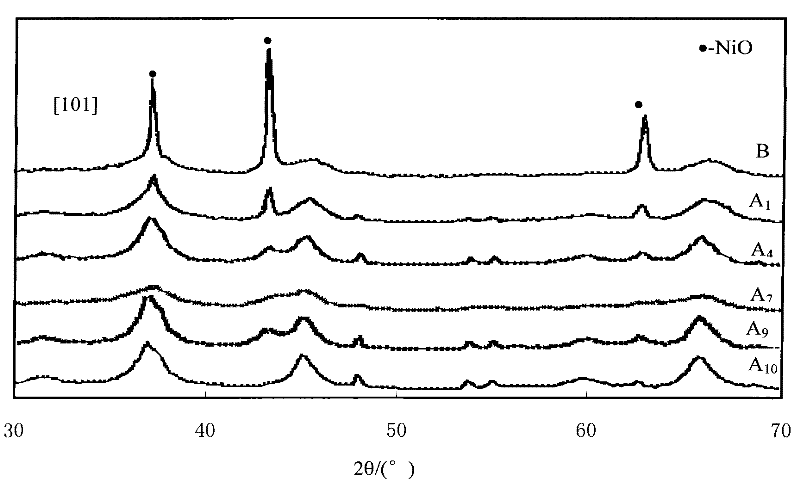

Image

Examples

Embodiment 1

[0025] 279.5g of nickel chloride hexahydrate and 11.0g of lanthanum nitrate hexahydrate are formulated into a mixed solution so that the concentration of the two salts in this solution is 0.6mol / L. After the two salts are all dissolved, add pseudoboehmite (containing Al 2 o 3 70% (mass fraction)) 92.9g, make slurry stand-by; Dissolve 318g sodium carbonate in water, be mixed with the precipitating agent solution that concentration is 1.0mol / L, stand-by; Add 1000mL clean water in 8000mL reactor , heat and turn on the stirring equipment. When the temperature rises to 80°C, keep the temperature in the kettle, start to add the mixed slurry and alkaline precipitant solution in parallel, and control the flow rate of the mixed slurry to 40mL / min and the flow rate of the alkaline precipitant solution to 55mL / min, keep the pH value of the slurry in the reactor at 7.2, when all the acidic mixed slurry is added, use the alkaline precipitant solution to adjust the pH value of the slurry...

Embodiment 2

[0027] The preparation process is the same as in Example 1, except that the concentration of the two salts in the solution is changed to 0.3mol / L, and the concentration of the precipitant solution is changed to 1.5mol / L, and the prepared nickel-based catalyst precursor is roasted at 550°C for 4 hours. , to obtain the roasted product of nickel-based catalyst precursor as A 2 , and the analysis results are shown in Table 1.

Embodiment 3

[0029] The preparation process is the same as in Example 1. Pre-add 1500mL of clean water to the 8000mL reactor to prepare the nickel-based catalyst precursor. After roasting at 550°C for 4 hours, the roasted product A of the nickel-based catalyst precursor is obtained. 3, and the analysis results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com