Lithium titanate composite material and preparation method thereof

A composite material, lithium titanate technology, applied in the direction of titanate, titanium compound, alkali metal titanate, etc., can solve the problem of not taking into account the high initial discharge specific capacity and good rate discharge performance, and achieve good rate Discharge performance, good uniform dispersion system, the effect of particle size is not easy to grow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This example illustrates the preparation of the lithium titanate composite material of the present invention.

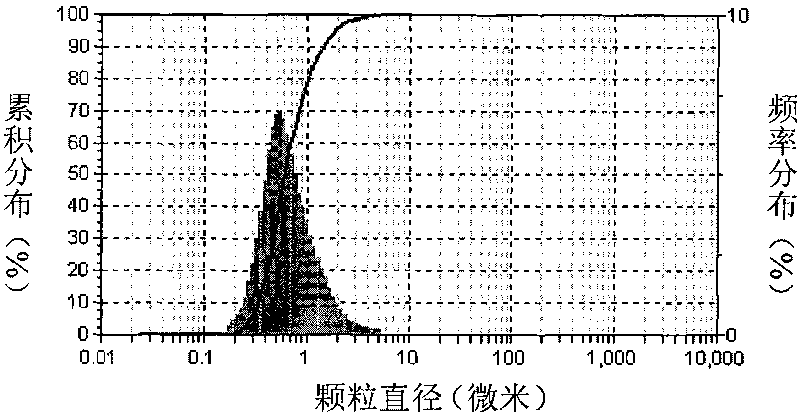

[0044] 21.6 g LiOH·H 2 O was dissolved in 180 grams of deionized water, and 9.7 grams of glucose was added. After the glucose was completely dissolved, D was added under stirring conditions. 50 0.2 microns, D 95 0.7 micron anatase TiO 2 Ultrafine powder 47.9 grams ( figure 1 for the TiO 2 SEM image of ultrafine powder), continue to stir the solution for 30 minutes, and dry it at 120°C to obtain the precursor after removing moisture. The precursor was sintered at a constant temperature of 800°C in a nitrogen atmosphere for 20 hours, and cooled naturally to room temperature to obtain a carbon-coated lithium titanate composite material M1. Based on the total amount of the lithium titanate composite material, the carbon The content is 5.4% by weight.

[0045] figure 2 The SEM image of the lithium titanate precursor after water removal was obtained by using...

Embodiment 2

[0051] This example illustrates the preparation of the lithium titanate composite material of the present invention.

[0052] 33.1 g LiNO 3 Dissolve in 60 grams of deionized water, and add 14.55 grams of sucrose, after the sucrose is completely dissolved, slowly add D 50 0.4 microns, D 95 0.85 micron rutile TiO 2 47.9 grams of superfine powder, continue to stir the solution for 30 minutes, dry at 130° C., and obtain the precursor after removing water. The precursor was sintered at a constant temperature of 900°C in a nitrogen atmosphere for 16 hours, and cooled naturally to room temperature to obtain the carbon-coated lithium titanate material M2 provided by the present invention. Based on the total amount of the lithium titanate composite material, carbon The content is 9.1% by weight. The average particle diameter of the lithium titanate is 1.5 microns.

Embodiment 3

[0054] This example illustrates the preparation of the lithium titanate composite material of the present invention.

[0055] 49.1 grams of lithium acetate dihydrate were dissolved in 100 grams of deionized water, and 9.7 grams of superfine carbon black (D 95 is 0.5 micron), under the condition of stirring, slowly add D 50 0.2 µm, D 95 0.85 micron brookite TiO 2 47.9 grams of superfine powder, continue to stir the solution for 30 minutes, leave the solution in a beaker, dry it at 130° C., and obtain a precursor after removing water. The precursor was sintered at a constant temperature of 950° C. in a nitrogen atmosphere for 6 hours, and naturally cooled to room temperature to obtain the carbon-coated lithium titanate material M3 provided by the present invention. Based on the total amount of the lithium titanate composite material, The carbon content is 14.2% by weight. The average particle diameter of the lithium titanate is 1.2 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com