Positive electrode active material precursor, preparation method thereof, and positive electrode active material

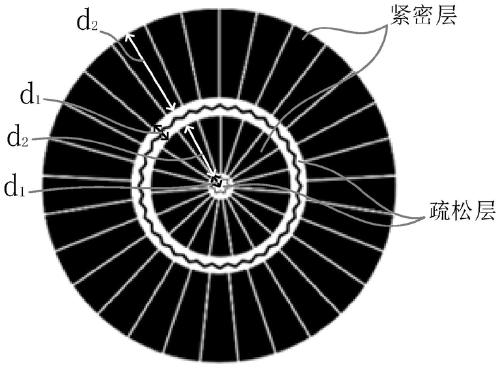

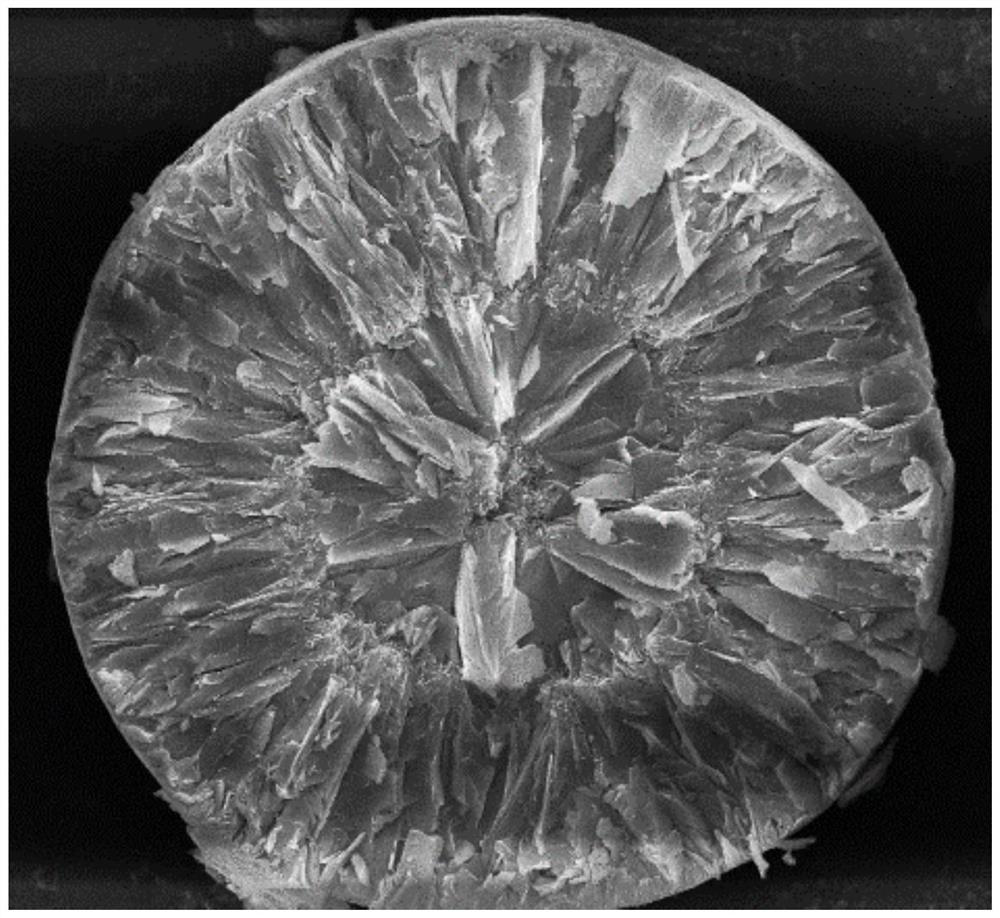

A technology of positive active materials and precursors, applied in the field of positive active materials and positive active material precursors, can solve the problems of reducing the comprehensive electrochemical performance of lithium-ion batteries, the difficulty of positive active materials to have comprehensive electrochemical performance, and low capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

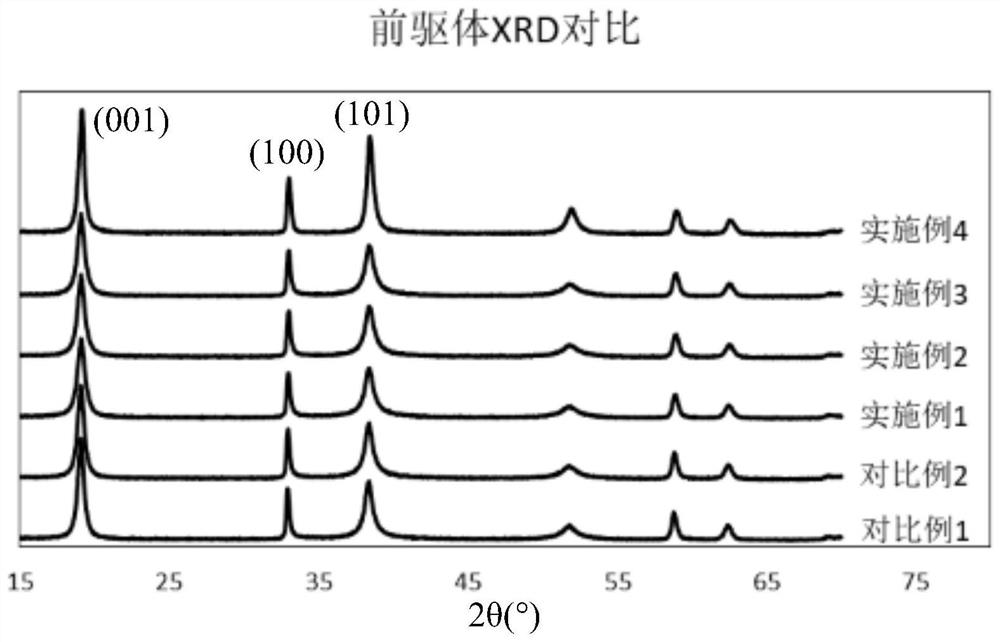

Embodiment 1

[0105] Preparation of positive electrode active material precursor

[0106] Nickel sulfate, cobalt sulfate, and manganese sulfate are configured into a mixed salt solution with a concentration of 1.5mol / L according to the molar ratio Ni:Co:Mn=8:1:1, and NaOH is configured into a precipitant solution with a concentration of 5mol / L. Aqueous ammonia with a concentration of 8 mol / L was used as complexing agent solution.

[0107] Add 10L of deionized water into the 18L controlled crystallization reactor, add a certain amount of concentrated ammonia water to make the ammonia concentration 0.2mol / L, and add a certain amount of NaOH solution to make the pH 12.20 to obtain the bottom liquid.

[0108] in N 2 Under a protective atmosphere, heat the bottom liquid to 55°C and maintain it. At a stirring speed of 800rpm, add the mixed salt solution, precipitant solution, and complexing agent solution into the bottom liquid in parallel, wherein the flow rate of the mixed salt solution is 1...

Embodiment 2

[0120] Different from Example 1, in the preparation of the positive electrode active material precursor:

[0121] Nickel sulfate, cobalt sulfate, and manganese sulfate are configured into a mixed salt solution with a concentration of 2.0mol / L according to the molar ratio Ni:Co:Mn=6:2:2, and NaOH is configured into a precipitant solution with a concentration of 3mol / L. Ammonia water with a concentration of 5 mol / L was used as complexing agent solution.

[0122]Add 12L deionized water to the 18L controlled crystallization reactor, add a certain amount of concentrated ammonia water to make the ammonia concentration 0.2mol / L, and add a certain amount of NaOH solution to make the pH 11.60 to obtain the bottom liquid.

[0123] in N 2 Under a protective atmosphere, heat the bottom liquid to 55°C and maintain it. At a stirring speed of 800rpm, add the mixed salt solution, precipitant solution, and complexing agent solution into the bottom liquid in parallel, wherein the flow rate of ...

Embodiment 3

[0125] Different from Example 1, in the preparation of the positive electrode active material precursor:

[0126] Nickel sulfate, cobalt sulfate, and manganese sulfate are configured into a mixed salt solution with a concentration of 2.0mol / L according to the molar ratio Ni:Co:Mn=90:5:5, and NaOH is configured into a precipitant solution with a concentration of 5mol / L. Ammonia water with a concentration of 10mol / L was used as complexing agent solution.

[0127] Add 6L of deionized water to an 18L controlled crystallization reactor, add a certain amount of concentrated ammonia water to make the ammonia concentration 0.4mol / L, and add a certain amount of NaOH solution to make the pH 12.00 to obtain the bottom liquid.

[0128] in N 2 Under a protective atmosphere, heat the bottom liquid to 55°C and maintain it. At a stirring speed of 800rpm, add the mixed salt solution, precipitant solution, and complexing agent solution into the bottom liquid in parallel, wherein the flow rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com