Anode material for lithium ion batteries and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, which can be applied to battery electrodes, secondary batteries, circuits, etc., and can solve the problems of poor high-rate performance of negative electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

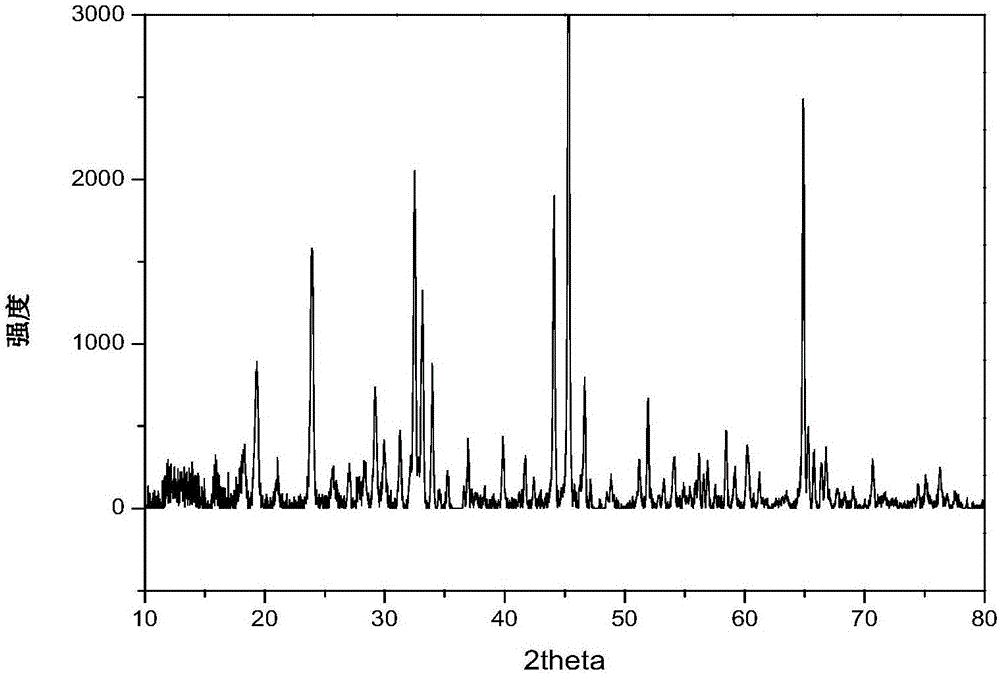

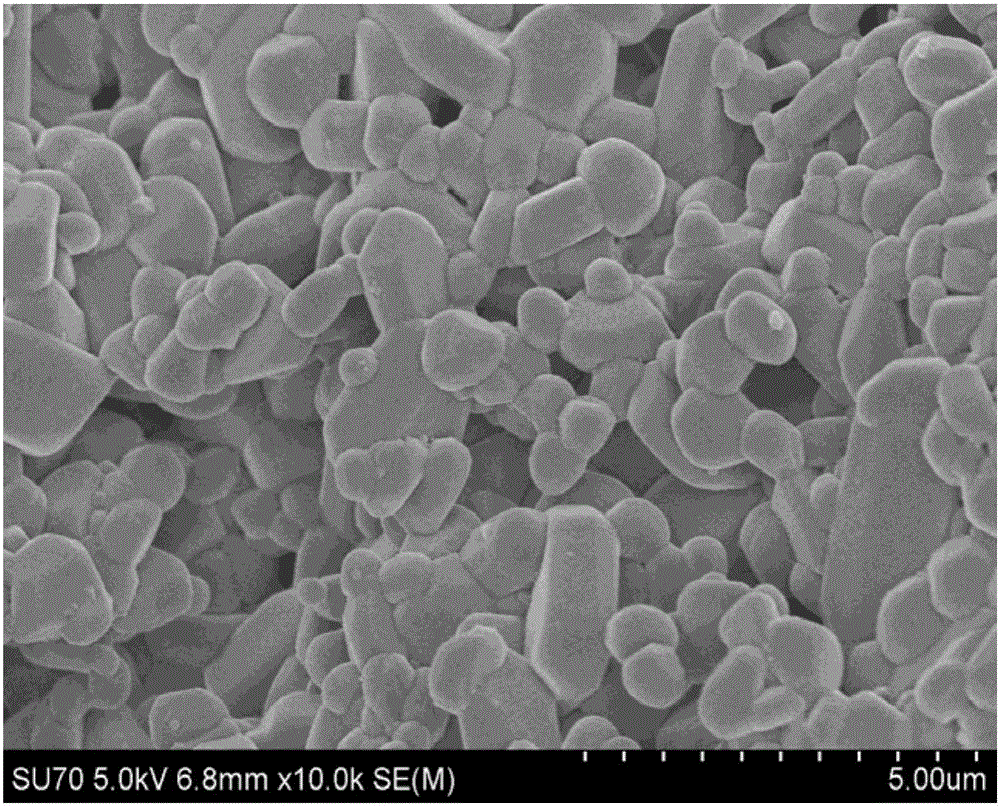

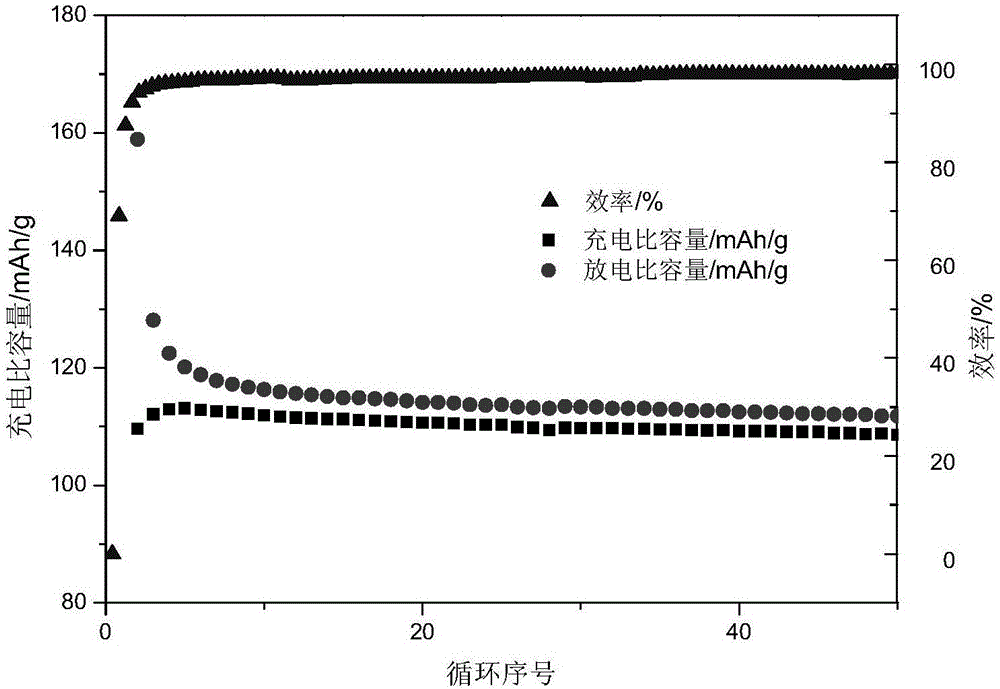

[0025] Weigh sodium chloride (1.4040g, 0.024mol), barium chloride (2.4987g, 0.012mol), strontium chloride (3.8041g, 0.024mol), lithium nitrate (6.6192g, 0.096mol), amorphous titanium dioxide (23.0014 g, 0.288mol) in an agate ball mill jar, use methanol as a solvent, ball mill for 5 hours, put the ground mixture into an oven at 70°C and dry for 20 hours, put the dried material in an agate mortar and grind it thoroughly, Put it in a muffle furnace to raise the temperature to 500°C at a heating rate of 1°C / min, and then heat it up to 1000°C at a heating rate of 4°C / min for 6 hours, and then heat it up to 1000°C at a heating rate of 4°C / min. material; its purity was determined by powder diffraction (XRD), as figure 1 Shown; Observe the morphology of described composite material with scanning electron microscope (SEM), as figure 2 As shown; Assemble the simulated battery in a glove box filled with argon, and measure its electrochemical performance, such as image 3 shown.

Embodiment 2

[0027] Weigh sodium acetate trihydrate (0.8165g, 0.006mol), barium nitrate (0.7507g, 0.003mol), strontium nitrate (1.2698g, 0.006mol), lithium carbonate (1.7734g, 0.024mol), anatase titanium dioxide ( 1.4040g, 0.072mol) in an agate ball mill jar, use ethanol as a solvent, ball mill for 10 hours, put the ground mixture in an oven at 80°C for 15 hours, put the dried material in an agate mortar and grind it thoroughly , placed in a muffle furnace to raise the temperature to 600°C at a heating rate of 5°C / min, and then heat it up to 800°C at a heating rate of 10°C / min for 4 hours, and then heat it up to 800°C at a heating rate of 10°C / min. The composite material; determine its purity by measuring powder diffraction (XRD); observe the morphology of the composite material with a scanning electron microscope (SEM); assemble a simulated battery in a glove box filled with argon, and measure its electrochemical performance.

Embodiment 3

[0029]Weigh sodium carbonate (1.2720g, 0.012mol), barium carbonate (1.1820g, 0.006mol), strontium nitrate (1.26982.5396g, 0.012mol), lithium chloride (2.0754g, 0.048mol), rutile titanium dioxide (11.5012g, 0.144mol) in an agate ball mill jar, use propanol as a solvent, ball mill for 15 hours, put the ground mixture in an oven at 90°C and dry for 10 hours, put the dried material in an agate mortar and grind it thoroughly, put In the muffle furnace, the temperature was raised to 800°C at a heating rate of 10°C / min, and then the temperature was raised to 900°C at a heating rate of 1°C / min for 1 hour, and the temperature was raised to 900°C at a heating rate of 1°C / min. Composite material; determine its purity by measuring powder diffraction (XRD); observe the morphology of the composite material with a scanning electron microscope (SEM); assemble a simulated battery in a glove box filled with argon, and measure its electrochemical performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com