Spinel phase coated lithium-rich material Li1.87Mn0.94Ni0.19O3, preparation method and application therefor

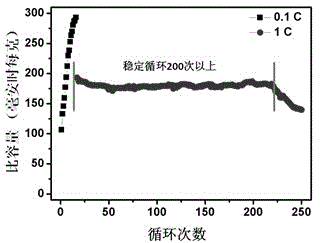

A lithium-rich material and spinel phase technology, applied in the field of electrochemistry, can solve the problems of poor cycle stability, poor storage performance, and low material gram capacity, and achieve the effects of reducing damage, slowing down direct contact, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

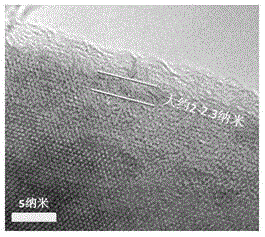

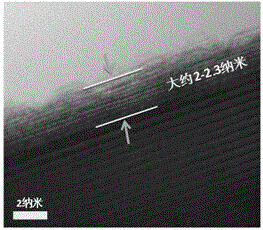

[0034] Lithium-rich material coated with spinel phase surface 1.87 mn 0.94 Ni 0.19 o 3 , including a lithium-rich material and a spinel phase coating layer coated on the outer layer of the lithium-rich material; the lithium-rich material is composed of Li element, Mn element, Ni element and O element, and the Li element, Mn element, The molar ratio of Ni element to O element is 1.87:0.94:0.19:3; the spinel phase cladding layer is manganese spinel.

[0035] The lithium-rich material Li coated on the surface of the spinel phase 1.87 mn 0.94 Ni 0.19 o 3 The preparation method comprises steps:

[0036] 1) Prepare 100ml of a mixed solution of manganese nitrate and nickel nitrate, the molar ratio of manganese nitrate to nickel nitrate is 5:1, and the total concentration of manganese ions and nickel ions in the mixed solution is 0.2mol / L;

[0037] 2) Gradually add 100ml of sodium carbonate solution to the mixture, the concentration of sodium carbonate solution is 0.2mol / L;

...

Embodiment 2

[0050] Lithium-rich material coated with spinel phase surface 1.87 mn 0.94 Ni 0.19 o 3 , including a lithium-rich material and a spinel phase coating layer coated on the outer layer of the lithium-rich material; the lithium-rich material is composed of Li element, Mn element, Ni element and O element, and the Li element, Mn element, The molar ratio of Ni element to O element is 1.87:0.94:0.19:3; the spinel phase cladding layer is manganese spinel.

[0051] The lithium-rich material Li coated on the surface of the spinel phase 1.87 mn 0.94 Ni 0.19 o 3 The preparation method comprises steps:

[0052] 1) Prepare 100ml of a mixed solution of manganese nitrate and nickel nitrate, the molar ratio of manganese nitrate to nickel nitrate is 4.9:1, and the total concentration of manganese ions and nickel ions in the mixed solution is 0.25mol / L;

[0053] 2) Gradually add 100ml of sodium carbonate solution to the mixture, the concentration of sodium carbonate solution is 0.25mol / L...

Embodiment 3

[0062] Lithium-rich material coated with spinel phase surface 1.87 mn 0.94 Ni 0.19 o 3 , including a lithium-rich material and a spinel phase coating layer coated on the outer layer of the lithium-rich material; the lithium-rich material is composed of Li element, Mn element, Ni element and O element, and the Li element, Mn element, The molar ratio of Ni element to O element is 1.87:0.94:0.19:3; the spinel phase cladding layer is manganese spinel.

[0063] The lithium-rich material Li coated on the surface of the spinel phase 1.87 mn 0.94 Ni 0.19 o 3 The preparation method comprises steps:

[0064] 1) Prepare 100ml of a mixed solution of manganese nitrate and nickel nitrate, the molar ratio of manganese nitrate to nickel nitrate is 5.1:1, and the total concentration of manganese ions and nickel ions in the mixed solution is 0.2mol / L;

[0065] 2) Gradually add 100ml of sodium carbonate solution to the mixture, the concentration of sodium carbonate solution is 0.2mol / L; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com