Battery negative electrode material and preparation method and application thereof

A battery negative electrode and composite material technology, applied in electrode manufacturing, battery electrodes, negative electrodes, etc., can solve problems such as low actual capacity and poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of battery negative electrode material, comprising the following steps:

[0030] After mixing MXene, nickel salt, weak base and water, perform a hydrothermal reaction to obtain a composite material of nickel hydroxide and MXene;

[0031] After mixing the composite material of nickel hydroxide and MXene with amidinothiourea, heat treatment is carried out to obtain the battery negative electrode material.

[0032] In the present invention, unless otherwise specified, all preparation materials are commercially available products well known to those skilled in the art.

[0033] In the invention, after mixing MXene, nickel salt, weak base and water, a hydrothermal reaction is carried out to obtain a composite material of nickel hydroxide and MXene. The present invention does not have any special limitation on the type of MXene, and the type well known to those skilled in the art can be used. In the present invention, the type of ...

Embodiment 1

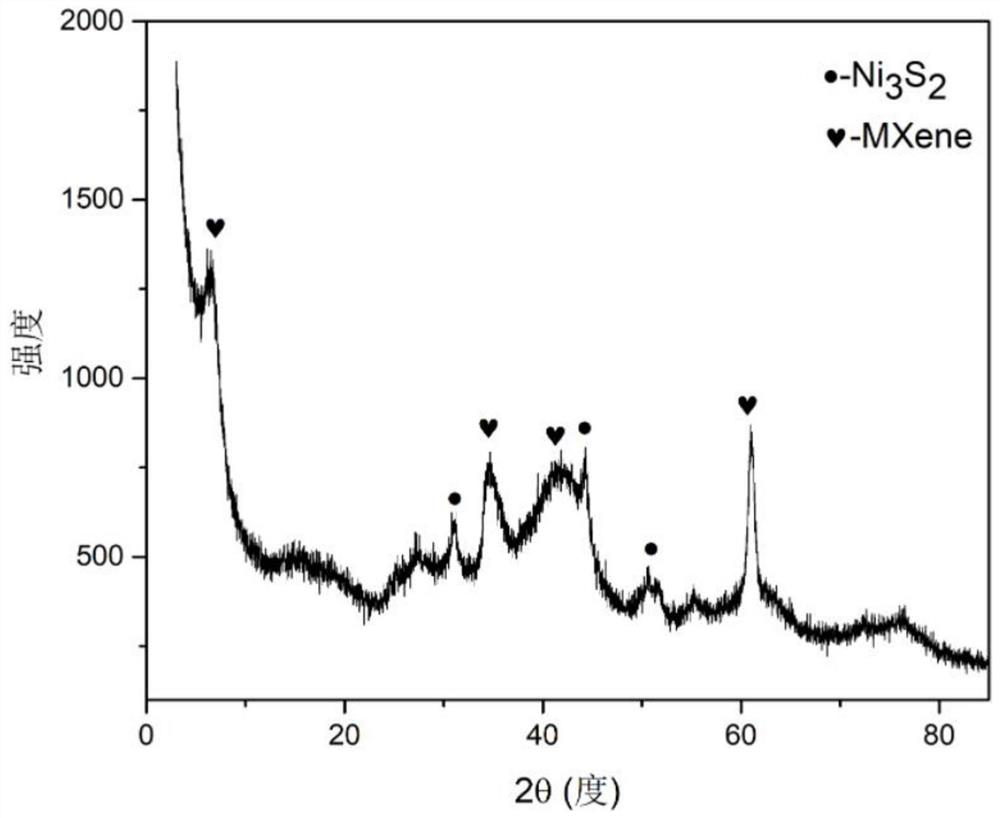

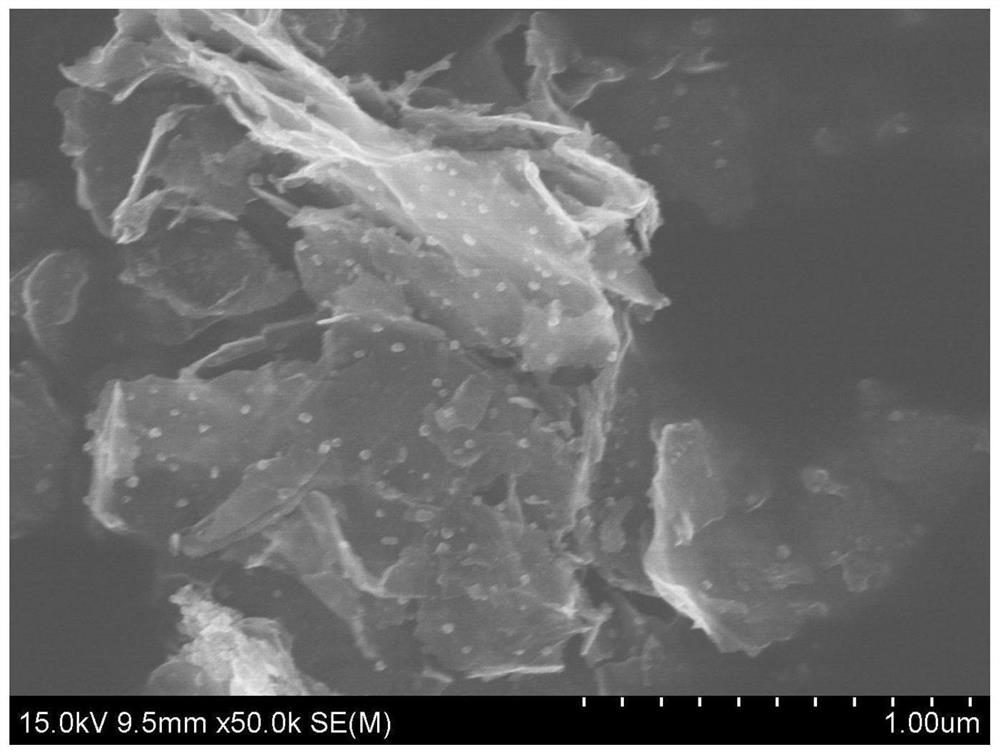

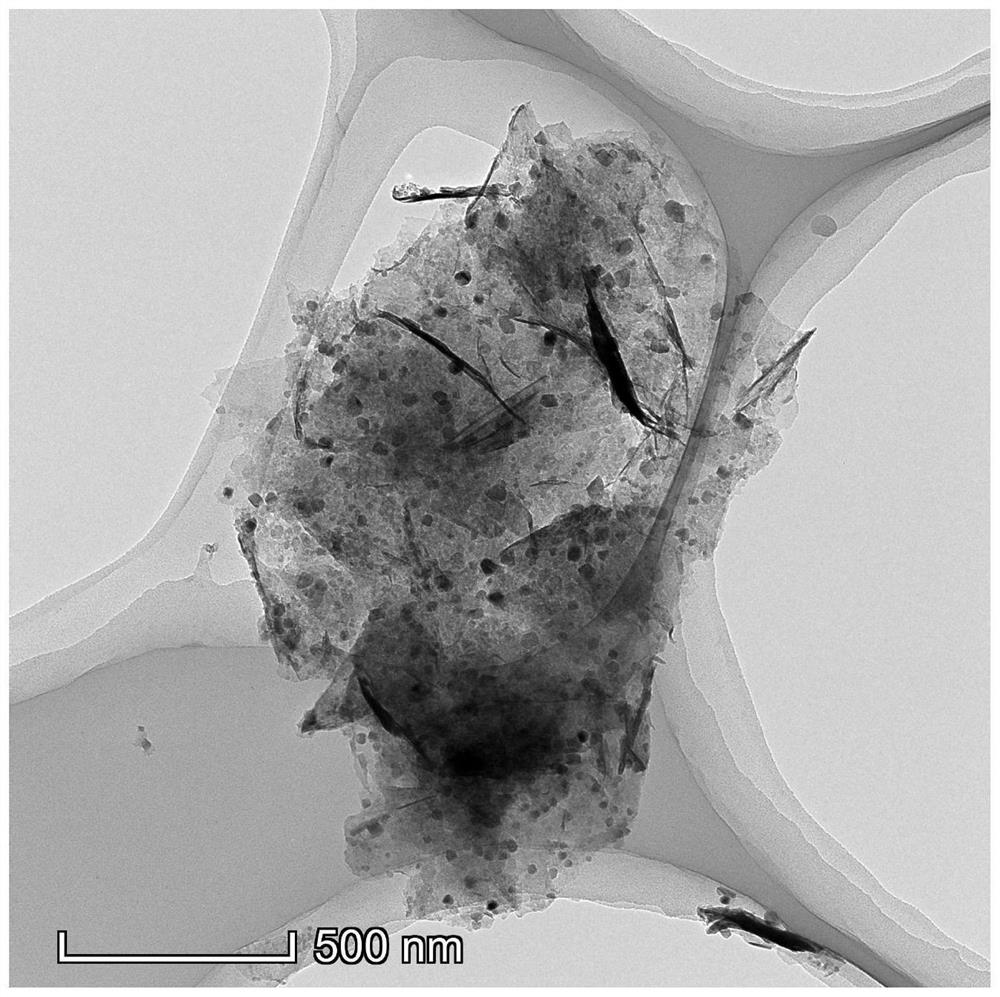

[0059] 1mmol (0.1676g) Ti 3 C 2 MXene and 70mL deionized water were mixed under ultrasonic conditions for 30min to obtain Ti 3 C 2 MXene dispersion with 0.75mmol NiSO 4 ·6H 2 O and 0.4 g of hexamethylenetetramine were mixed for 30 min under stirring, then transferred to a hydrothermal reaction kettle, carried out a hydrothermal reaction for 4 h at a temperature of 100° C., cooled to room temperature, followed by centrifugation and drying. Get Nickel Hydroxide and Ti 3 C 2 Composite materials of MXene;

[0060] The 0.1g nickel hydroxide and Ti 3 C 2 The composite material of MXene, 0.02g of amidinothiourea and 60mL of deionized water were mixed under stirring conditions for 30min and then dried. After the dried sample was ground for 5min, it was transferred to a tube furnace, under the protection of argon, with 5 The heating rate of ℃ / min was raised to 350 ℃, and after 1.5h of heat preservation, it was cooled to room temperature with the furnace, and the battery negat...

Embodiment 2

[0063] 1mmol (0.1676g) Ti 3 C 2 MXene and 80mL deionized water were mixed under ultrasonic conditions for 30min to obtain Ti 3 C 2 MXene dispersion with 0.5mmol NiCl 2 ·6H 2 O and 0.4 g of hexamethylenetetramine were mixed for 30 min under stirring, then transferred to a hydrothermal reaction kettle, carried out a hydrothermal reaction at a temperature of 150° C. for 3 h, cooled to room temperature, followed by centrifugation and drying. Get Nickel Hydroxide and Ti 3 C 2 Composite materials of MXene;

[0064] The 0.1g nickel hydroxide and Ti 3 C 2 The composite material of MXene, 0.01g amidinothiourea and 60mL deionized water were mixed under stirring conditions for 30min and then dried. After the dried sample was ground for 5min, it was transferred to a tube furnace. The heating rate of ℃ / min was raised to 350 ℃, and after 1.5h of heat preservation, it was cooled to room temperature with the furnace, and the battery negative electrode material (Ti 3 C 2 MXene and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com