Preparation method of wide-temperature methanation catalyst

A technology of methanation catalysts and additives, which is applied in the field of wide-temperature methanation catalysts and their preparation, can solve the problems of low Ni content, poor activity, and high catalyst reduction temperature, and achieve strong anti-sintering ability, low activation temperature, and mechanical high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

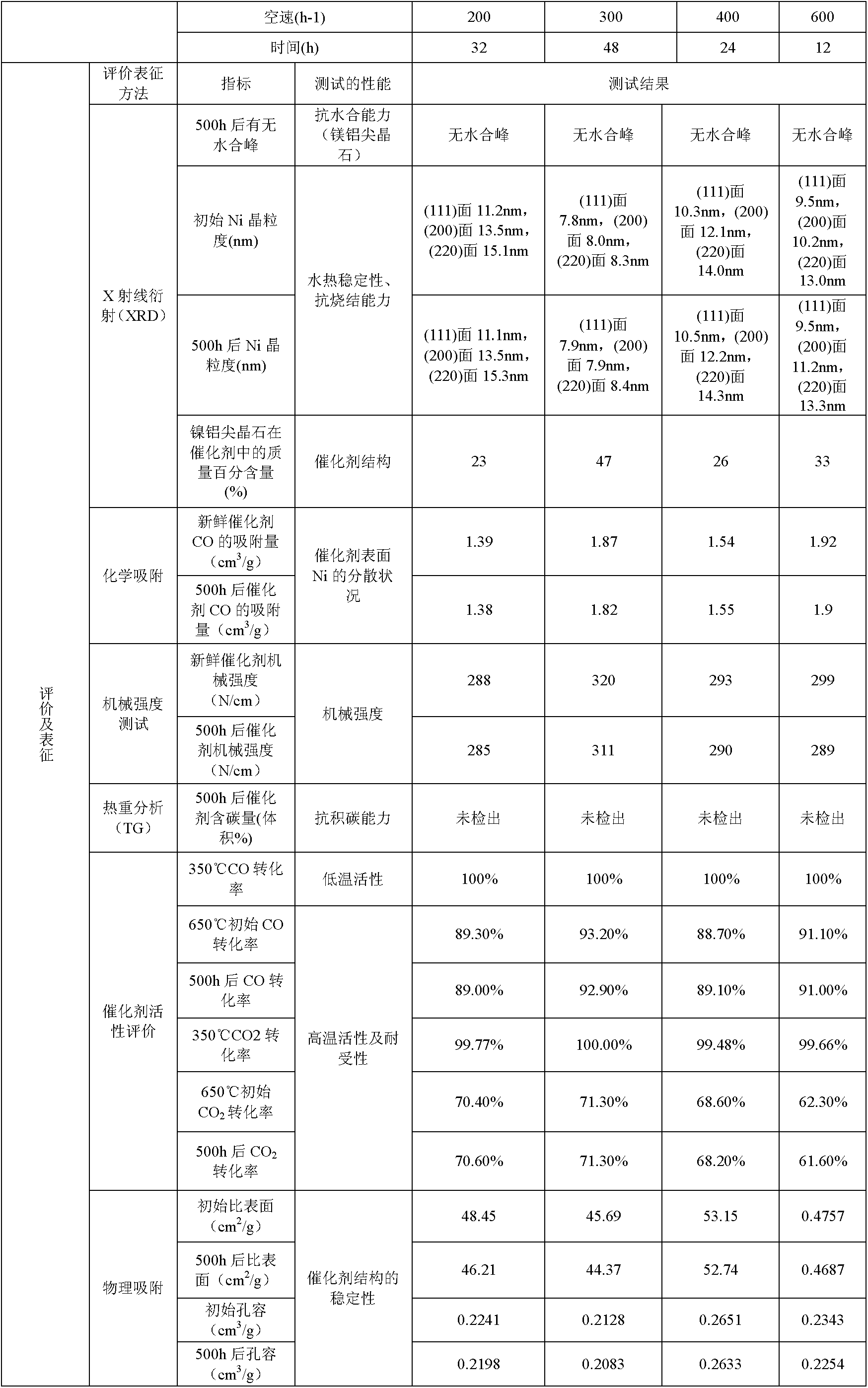

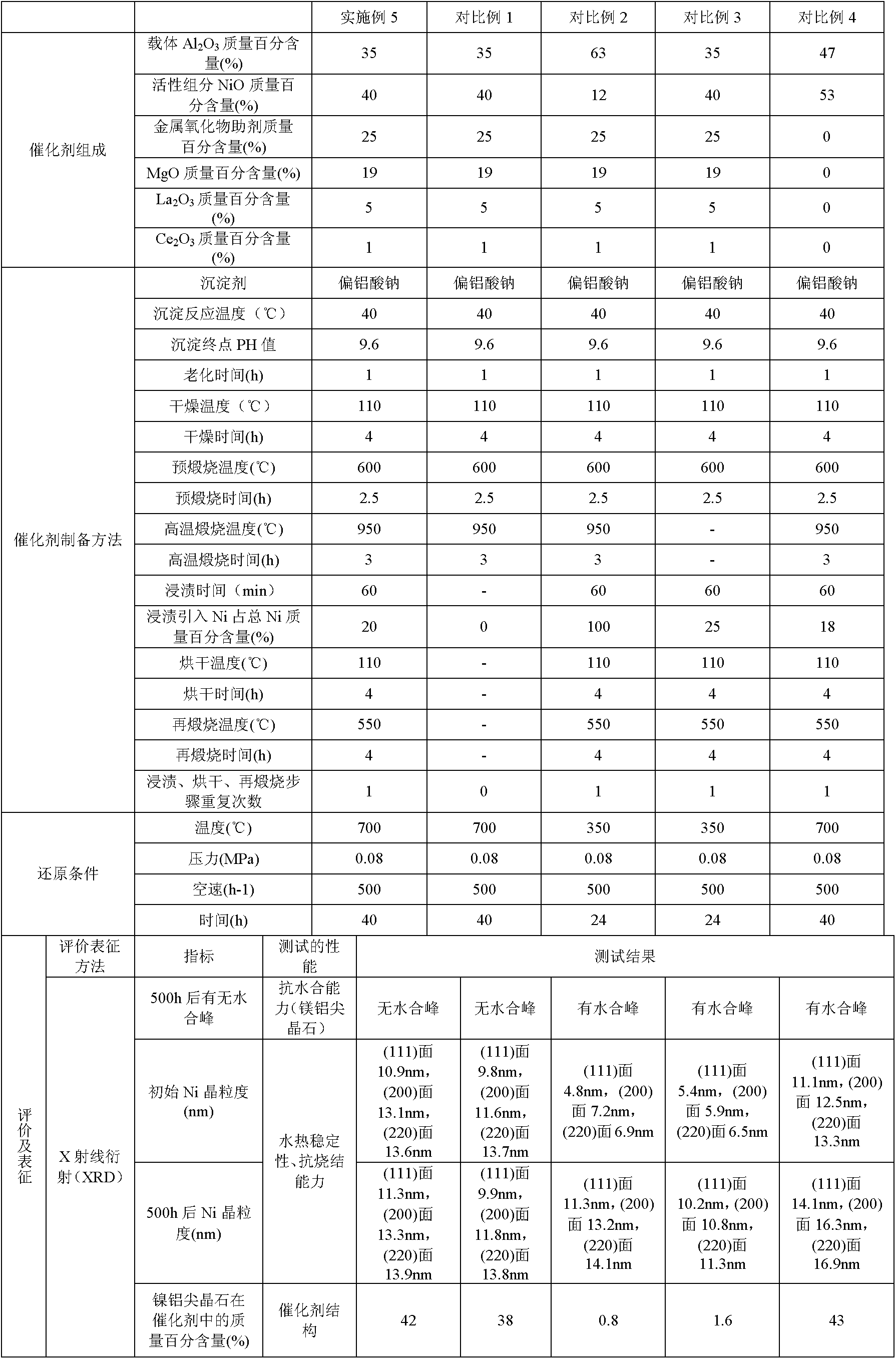

Examples

preparation example Construction

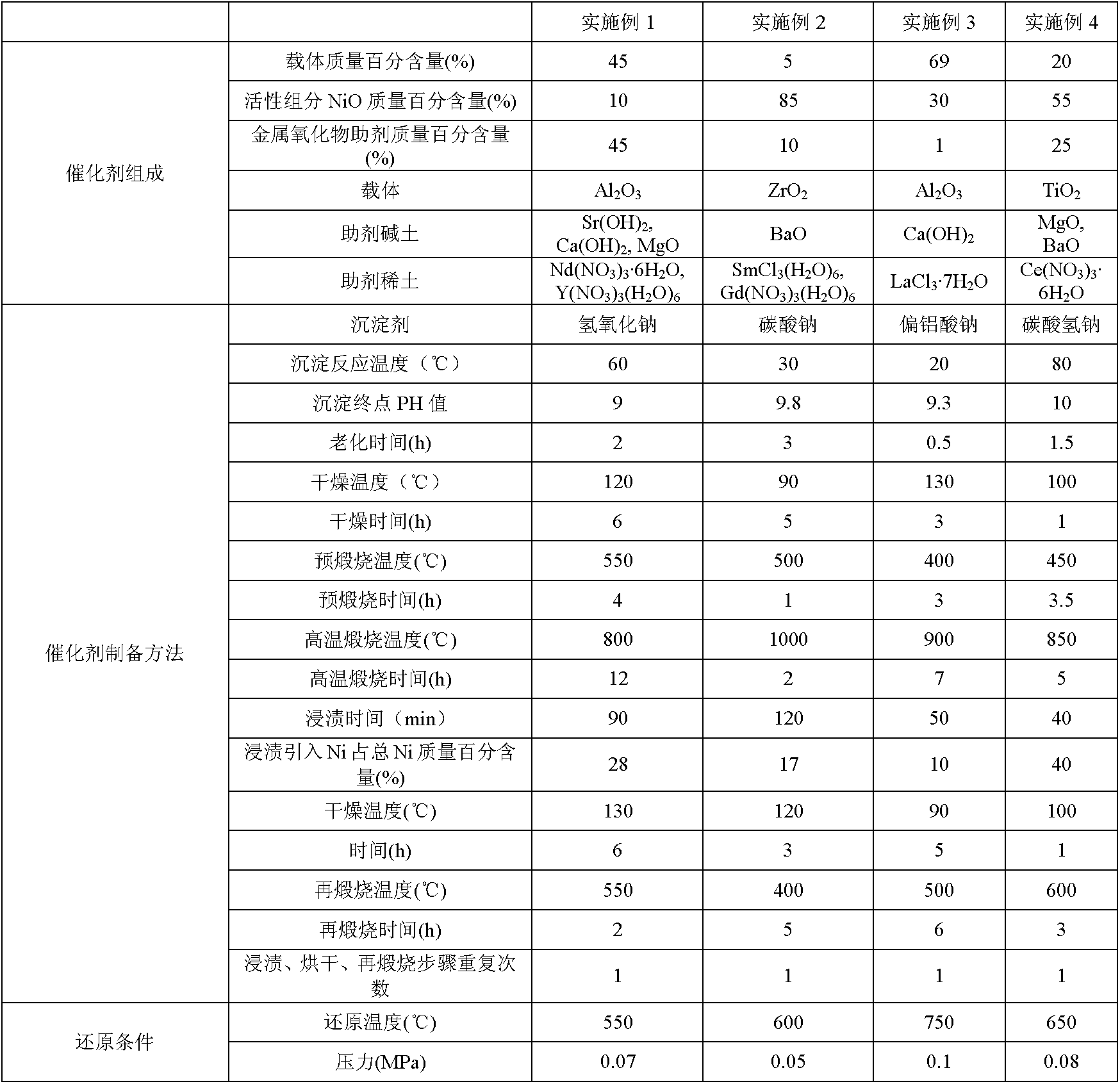

[0037] For this reason, the preparation method of a kind of wide temperature methanation catalyst of the present invention mainly comprises:

[0038] First, according to the mass composition of the carrier, active component and metal additive in the finished catalyst, by mixing a part of the carrier in the form of the corresponding metal salt, oxide or oxide hydrate of the active component in water such as deionized water and the corresponding metal salt, oxide or oxide hydrate of the metal oxide additive, and stirred to form a mixed solution, and undergo precipitation reaction with a precipitating agent under liquid phase conditions to obtain a precipitate. Next, the precipitate is dried and calcined at a high temperature to convert it into a corresponding composite metal oxide;

[0039] Next, the remaining part of the corresponding metal salt of the active component is dissolved in water to form a solution, and then the metal ions of the active component are supported on the...

Embodiment 1

[0068] Prepare the wide-temperature methanation catalyst of following mass composition by the method of the present invention: Carrier Al 2 o 3 : 45%; active component NiO: 10%; metal oxide additives: 45% (of which MgO: 15%, CaO: 10%, SrO: 10%, Nd 2 o 3 : 4%, Y 2 o 3 : 6%).

[0069] Take by weighing 28kg of nickel nitrate hexahydrate, 10.5kg of neodymium nitrate hexahydrate, and yttrium nitrate hexahydrate of 20.3kg in 173L of water, fully stir until fully dissolved, then drop into 15kg of light magnesium oxide, 13.2kg of calcium hydroxide, 11.7kg of strontium hydroxide and 64.3kg of pseudoboehmite were fully stirred to form mixed solution I; 16.94kg of sodium hydroxide was weighed and dissolved in 56L of water to prepare precipitant solution II; mixed solution I and precipitant Solution II was subjected to precipitation reaction at 60°C. The precipitation process was fully stirred, and the pH value at the end of the precipitation reaction was 9. This was the first time t...

Embodiment 2

[0071] Prepare the wide-temperature methanation catalyst of following mass composition by the inventive method: carrier ZrO2: 5%; Active component NiO: 85%; Metal oxide additive: 10% (wherein BaO: 8%, Sm 2 o 3 : 1%, Gd 2 o 3 :1%).

[0072] Take by weighing 274.7kg of nickel nitrate hexahydrate, 2.0kg of samarium chloride hexahydrate, and 2.4kg of gadolinium nitrate hexahydrate, add to 955L of water, fully stir until fully dissolved, then drop into 8.0kg of barium oxide, 5.0kg of zirconia, Stir fully to form mixed solution I; weigh 101.84kg of sodium carbonate, dissolve it with 261L of water, and prepare precipitant solution II; carry out precipitation reaction between mixed solution I and precipitant solution II at 30°C, and fully stir during the precipitation process. The pH value at the end of the precipitation reaction is 9.8, which is the first introduction of the active component; after aging the mixed solution after the precipitation reaction for 3 hours, separate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com