Lithium ion battery ternary material with double-coated surface and preparation method thereof

A technology of lithium-ion batteries and ternary materials, applied in electrical components, battery electrodes, secondary batteries, etc., can solve problems such as easy peeling off of the coating layer, cumbersome process, discounted coating effect, etc., to improve capacity and stability , uniform particle size distribution, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

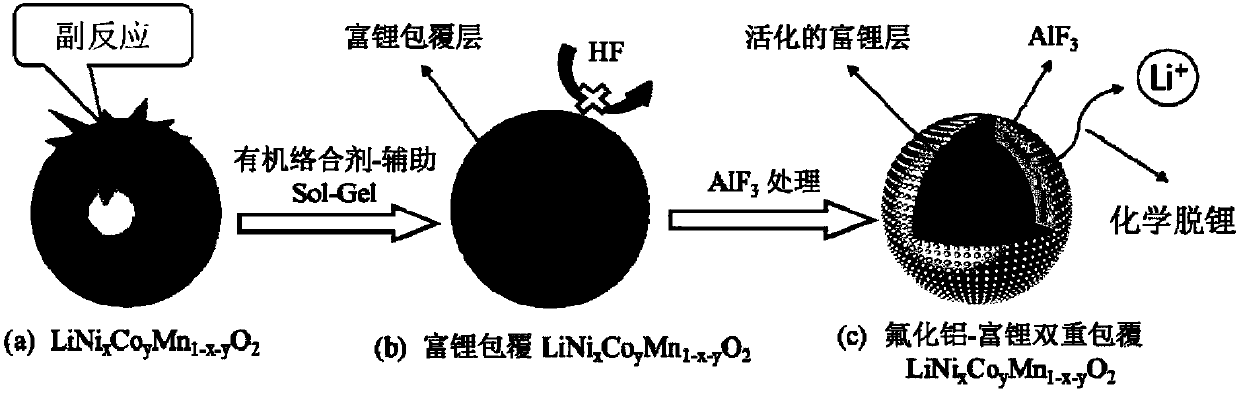

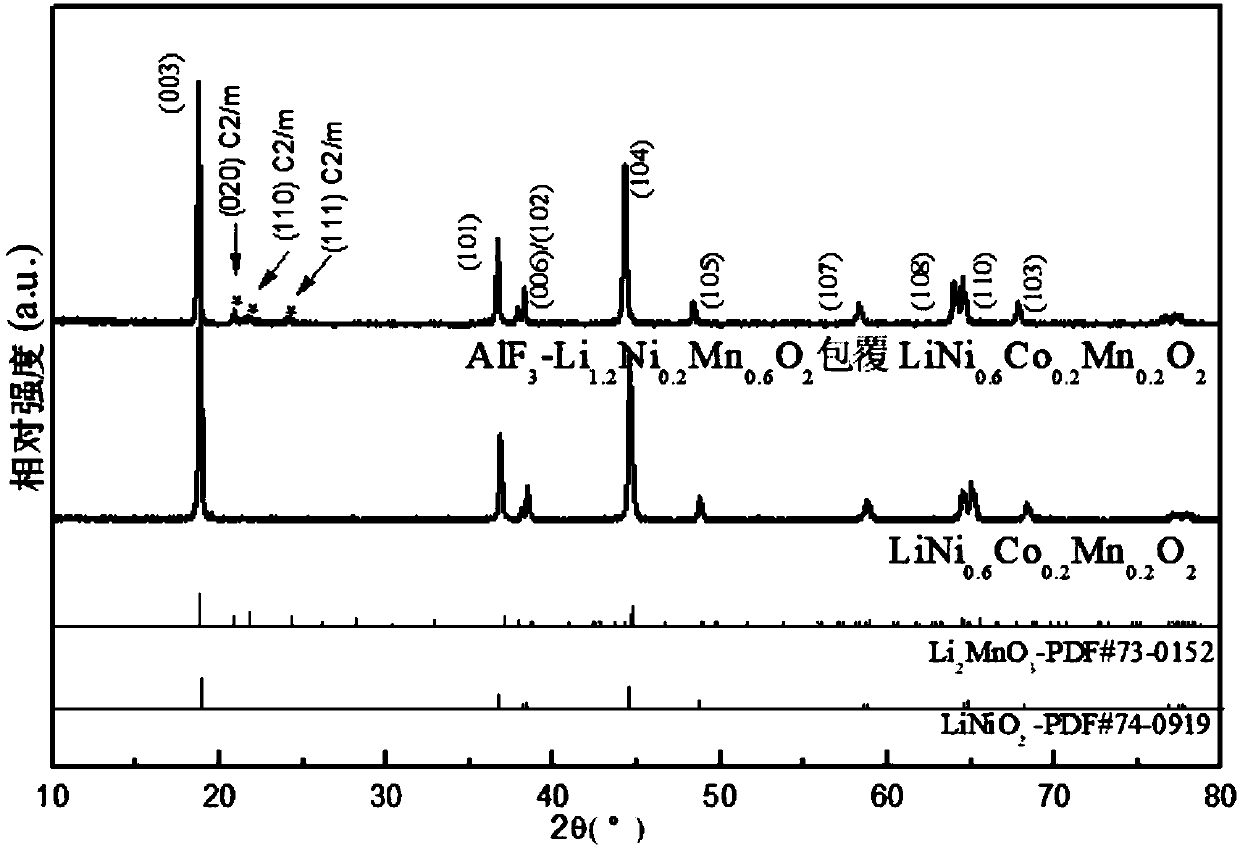

[0043] Disperse citric acid (total metal ion molar ratio of lithium, nickel and manganese is 3:1) in deionized water evenly to obtain a dispersion; under the action of ultrasound and stirring, add 0.05mol in parallel to the dispersion Lithium acetate solution, nickel acetate solution and manganese acetate solution of / L, keep stirring until gel appears (wherein, ultrasonic frequency is 40kHz, and ultrasonic power is 450W, and stirring speed is 450r / min; Lithium ion, nickel ion and manganese ion The molar ratio is 6:1:3);

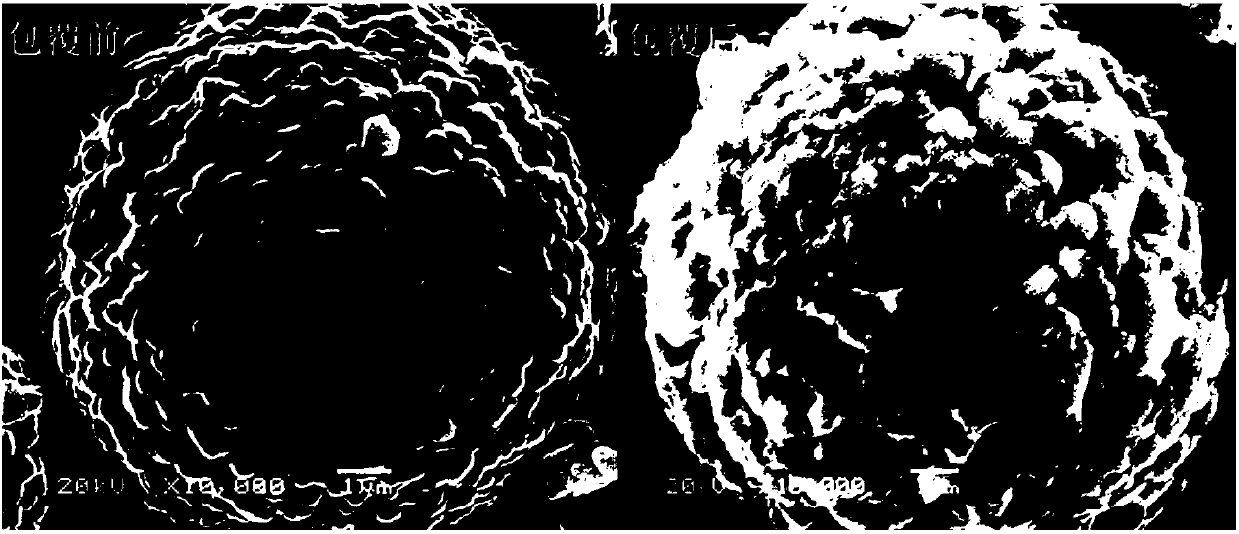

[0044] Will LiNi 0.6 co 0.2 mn 0.2 o 2 The ternary material was immersed in the above gel, and the mixture was continuously stirred for 20 minutes. The resulting mixture was dried and tempered. The tempering temperature was 700°C. 0.6 co 0.2 mn 0.2 o 2 Formation of Li on the surface of ternary materials 1.2 Ni 0.2 mn 0.6 o 2 (lithium-rich layered oxide) cladding layer; weigh the compound after tempering and disperse it in ethanol solvent, and stir...

Embodiment 2

[0050] Disperse polyvinylpyrrolidone (total metal ion molar ratio of lithium, nickel and manganese is 2:1) in ethanol solvent to obtain a dispersion liquid; add concentration of 0.04mol / L to the dispersion liquid under the action of ultrasound and stirring Lithium chloride solution, nickel chloride solution and manganese chloride solution, keep stirring until gel appears (wherein, ultrasonic frequency is 40kHz, and ultrasonic power is 400W, and stirring speed is 400r / min; Lithium ion, nickel ion and manganese ion The molar ratio is 3:1:1);

[0051] Will LiNi 0.5 co 0.2 mn 0.3 o 2 The ternary material was immersed in the above gel and kept stirring for 20 minutes. The resulting mixture was dried and tempered. The tempering temperature was 750°C. 0.5 co 0.2 mn 0.3 o 2 Formation of Li on the surface of ternary materials 1.2 [Ni 1 / 2 mn 1 / 2 ] 0.8 o 2 Coating layer; weigh the tempered compound and disperse it in deionized water, stir it ultrasonically to make it evenly d...

Embodiment 3

[0054] Disperse tartaric acid (total metal ion molar ratio of lithium, nickel, cobalt, and manganese is 4:1) in ethanol solvent to obtain a dispersion; under the action of ultrasound and stirring, add the concentration of 0.05 to the dispersion in parallel. mol / L lithium chloride solution, nickel chloride solution and manganese chloride solution, keep stirring until gel appears (wherein, ultrasonic frequency is 50kHz, ultrasonic power is 500W, and stirring speed is 400r / min; Lithium ion, nickel ion, The molar ratio of cobalt ions and manganese ions is according to Li 1.2 [Ni 1 / 3 co 1 / 3 mn 1 / 3 ] 0.8 o 2 Add to);

[0055] Will LiNi 0.8 co 0.1 mn 0.1 o 2 The ternary material was immersed in the above gel and kept stirring for 20 minutes. The resulting mixture was dried and tempered. The tempering temperature was 650°C. 0.8 co 0.1 mn 0.1 o 2 Formation of Li on the surface of ternary materials 1.2 [Ni 1 / 3 co 1 / 3 mn 1 / 3 ] 0.8 o 2 Coating layer; weigh the tempere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com