High-nickel positive electrode ternary material for lithium ion battery, and preparation method and application thereof

A lithium-ion battery, ternary material technology, applied in battery electrodes, positive electrodes, electrical components, etc., can solve the problem of high cost and achieve the effects of low cost, simple synthesis conditions and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

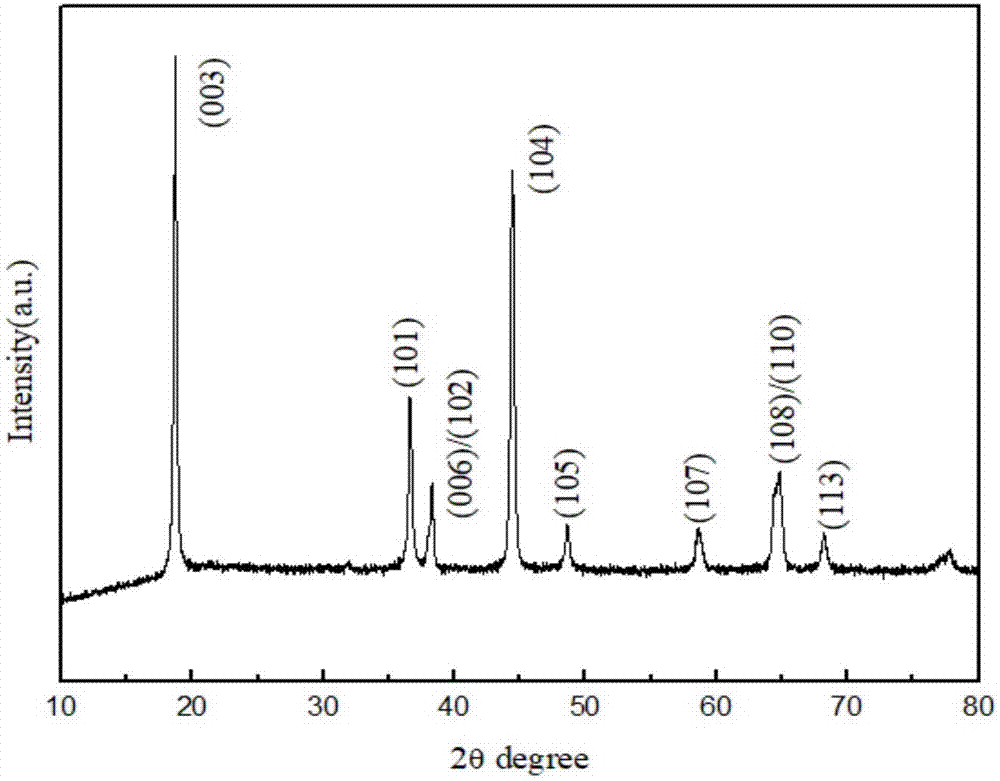

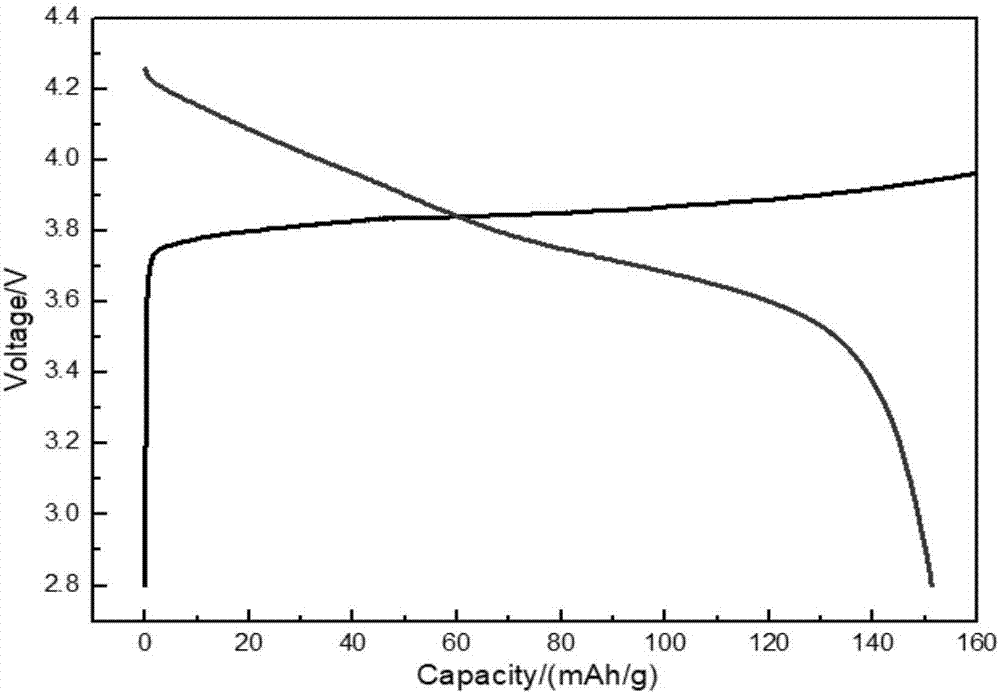

[0024] A kind of high-nickel positive electrode ternary material for lithium ion battery, described high-nickel positive electrode ternary material mainly is made up of lithium, nickel, cobalt, manganese, oxygen, wherein Ni, the existence valence state of Co and Mn in the compound are respectively +2 / +3, +3 and +4 valence, typical hexagonal a-NaFeO 2 Layered structure.

[0025] The preparation method of above-mentioned a kind of lithium-ion battery high-nickel cathode ternary material, namely with Ni 0.8 co 0.1 mn 0.1 (OH) 2 LiNi, a high-nickel positive electrode ternary material for lithium-ion batteries, was prepared by high-temperature solid-state sintering method using three different lithium salts as lithium sources. 0.8 co 0.1 mn 0.1 o 2 .

[0026] The preparation method of the above-mentioned high-nickel positive electrode ternary material for a lithium ion battery specifically comprises the following steps:

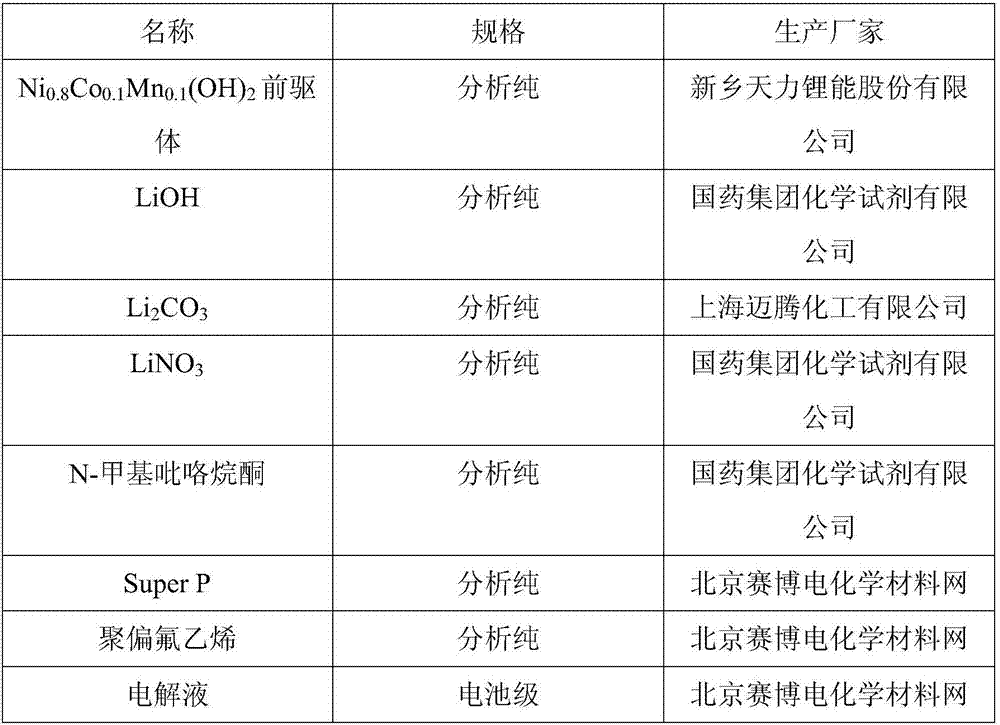

[0027] Weigh 3g Ni respectively 0.8 co 0.1 mn 0....

Embodiment 2

[0042] A kind of high-nickel positive electrode ternary material for lithium ion battery, described high-nickel positive electrode ternary material mainly is made up of lithium, nickel, cobalt, manganese, oxygen, wherein Ni, the existence valence state of Co and Mn in the compound are respectively +2 / +3, +3 and +4 valence, typical hexagonal a-NaFeO 2 Layered structure.

[0043] The preparation method of above-mentioned a kind of lithium-ion battery high-nickel cathode ternary material, namely with Ni 0.8 co 0.1 mn 0.1 (OH) 2 LiNi, a high-nickel positive electrode ternary material for lithium-ion batteries, was prepared by high-temperature solid-state sintering method using three different lithium salts as lithium sources. 0.8 co 0.1 mn 0.1 o 2 .

[0044] The preparation method of the above-mentioned high-nickel positive electrode ternary material for a lithium ion battery specifically comprises the following steps:

[0045] Weigh 3g Ni respectively 0.8 co 0.1 mn 0....

Embodiment 3

[0050] A kind of high-nickel positive electrode ternary material for lithium ion battery, described high-nickel positive electrode ternary material mainly is made up of lithium, nickel, cobalt, manganese, oxygen, wherein Ni, the existence valence state of Co and Mn in the compound are respectively +2 / +3, +3 and +4 valence, typical hexagonal a-NaFeO 2 Layered structure.

[0051] The preparation method of above-mentioned a kind of lithium-ion battery high-nickel cathode ternary material, namely with Ni 0.8 co 0.1 mn 0.1 (OH) 2 LiNi, a high-nickel positive electrode ternary material for lithium-ion batteries, was prepared by high-temperature solid-state sintering method using three different lithium salts as lithium sources. 0.8 co 0.1 mn 0.1 o 2 .

[0052] The preparation method of the above-mentioned high-nickel positive electrode ternary material for a lithium ion battery specifically comprises the following steps:

[0053] Weigh 4g Ni respectively 0.8 co 0.1 mn 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com