Membrane-type gas enrichment device based on polyimide film

A polyimide film and concentrator technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of gas flow limitation, reduction of effective contact, and unfavorable improvement of enrichment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 - polyimide membrane type gas enricher

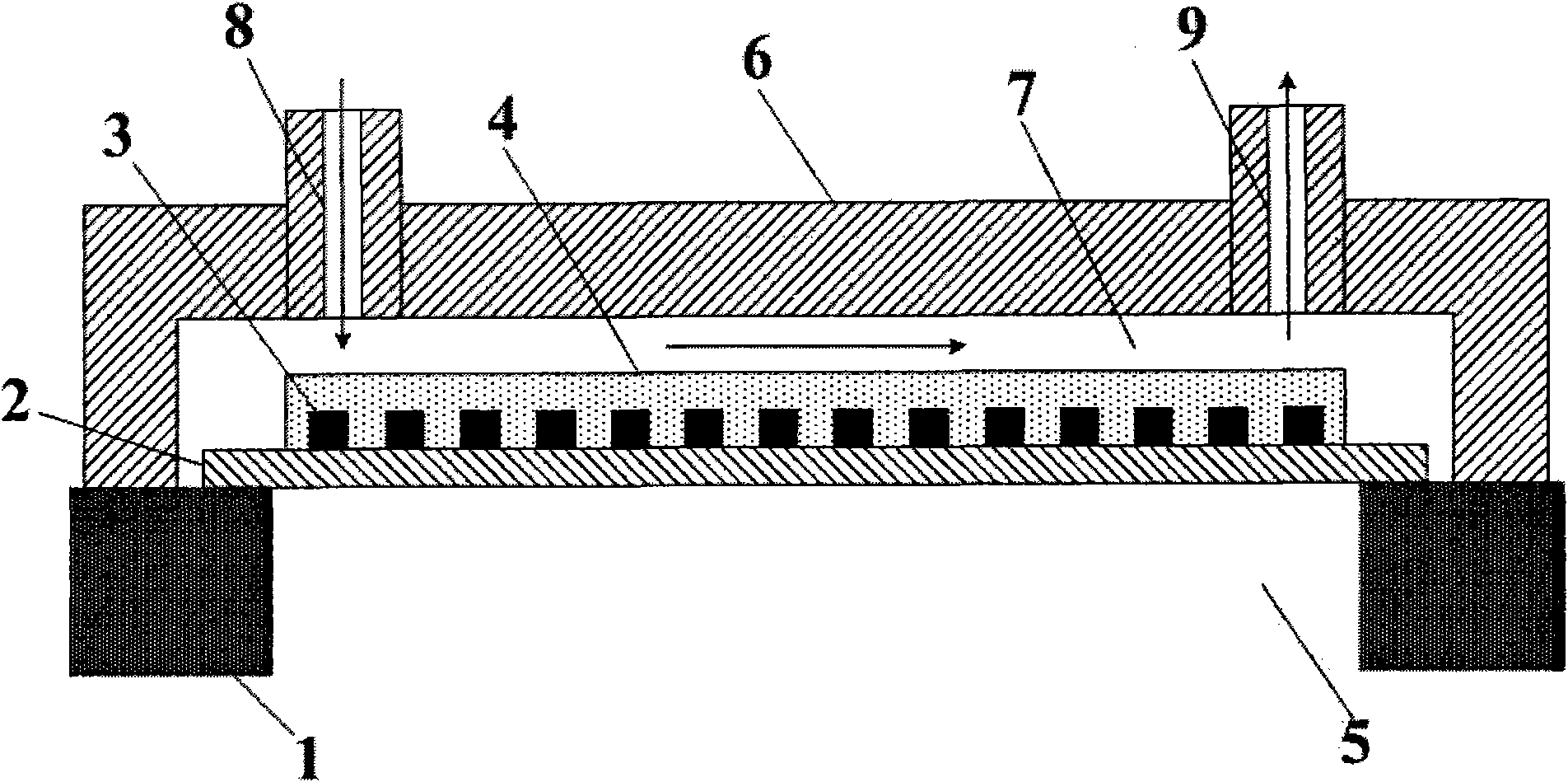

[0019] figure 1 It is a structural schematic diagram of a gas concentrator based on a polyimide diaphragm, which mainly includes a silicon substrate 1, a suspended diaphragm 2 (polyimide film), a thin film heater 3, an adsorption film 4, a cavity 5, and a top cover 6 (glass top cover), gas passage 7, air inlet 8, air outlet 9. Typically, about 500 μm thick silicon is used as the substrate. Firstly, a polyimide film was prepared by spin-coating method on the front side of the silicon substrate 1, and then cured at 380°C under a nitrogen atmosphere. Heat at a rate of 220°C for 30 minutes, and finally heat to 380°C for 1 hour. After the polyimide film is prepared, a metal platinum film with a thickness of about 200 nm is deposited on it by magnetron sputtering, and a serpentine film heater 3 is formed by photolithography etching. Then, reactive ion etching (DRIE) is used to etch away the silicon substrate 1 below the h...

Embodiment 2

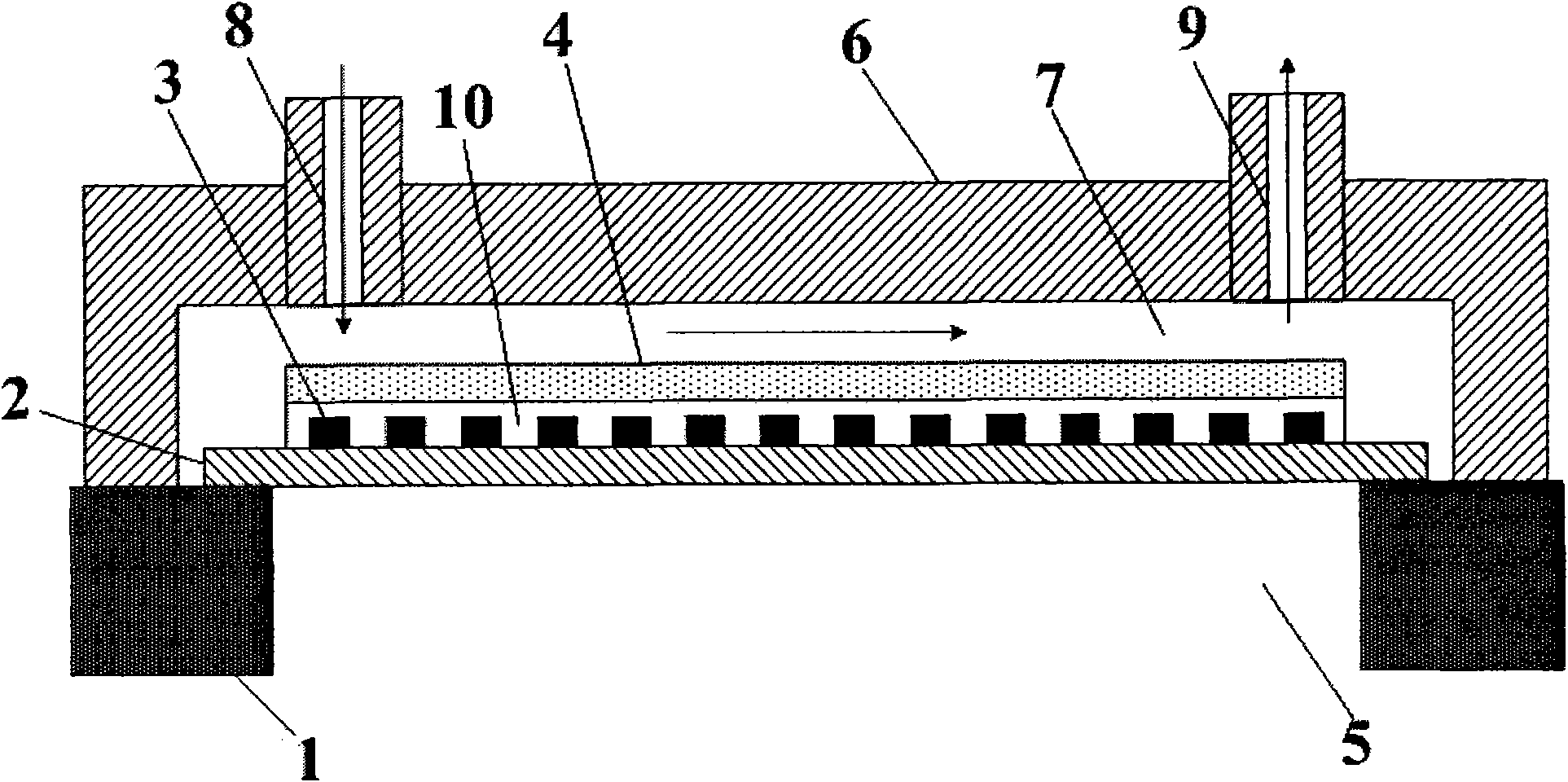

[0021] Example 2 - polyimide membrane type gas enricher with heat conduction layer

[0022] figure 2 It is a structural schematic diagram of a polyimide membrane type gas enricher with a heat conducting layer of the present invention. Its main implementation method is the same as Example 1, the difference is that after the heating element 3 is prepared, a layer of AlN film is prepared on the heating element 3 as a heat conduction film 10 by radio frequency sputtering method, the film thickness is about 1 μm, and then An adsorption film 4 is deposited thereon. Due to the excellent thermal conductivity of AlN, the temperature rise rate of the enricher is faster, and the temperature can be raised to 250°C within 70s, and the enrichment rate is also increased, about 340.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com