Method for separating and enriching valuable metals from copper anode mud

A copper anode slime, separation and enrichment technology, applied in the direction of improvement of process efficiency, etc., can solve the problems of high enrichment ratio of precious metals, short process, easy corrosion of equipment, etc., and achieve good comprehensive recovery benefits, good operating environment, and labor low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

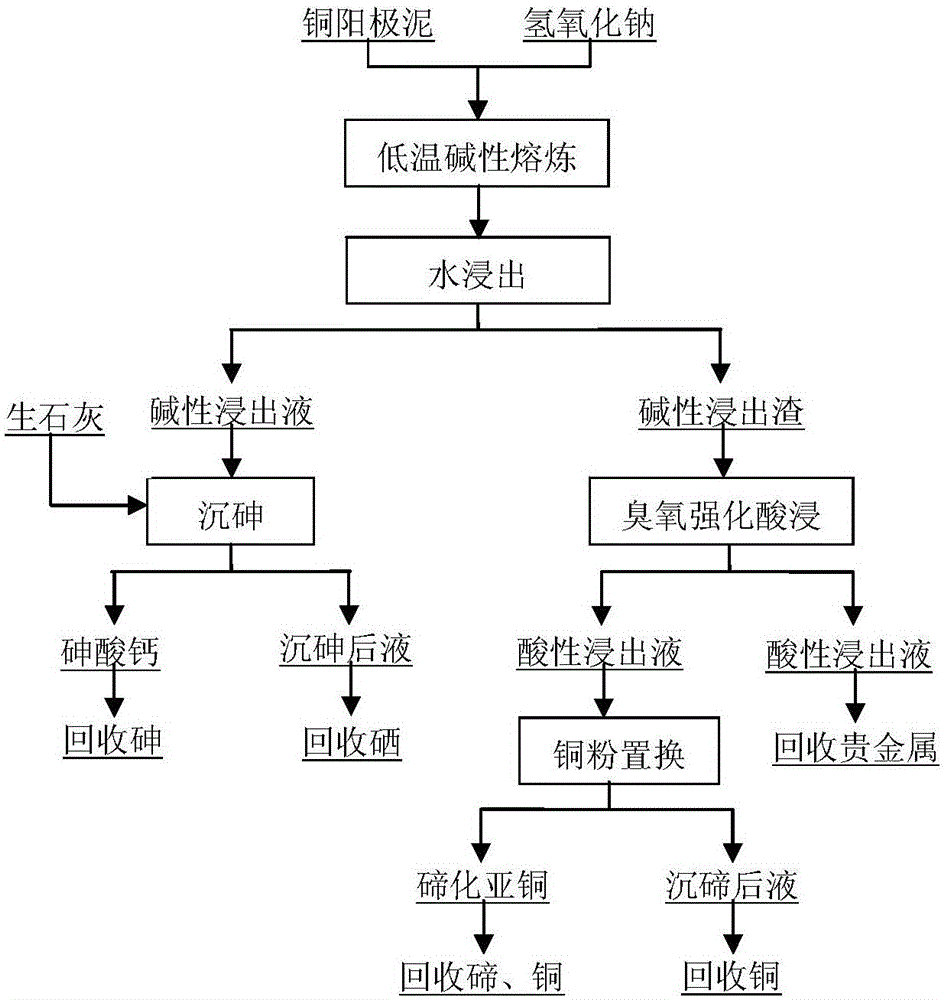

[0044] A method for separating and enriching valuable metals from copper anode slime according to the present invention, its process flow chart is as follows figure 1 shown, including the following steps:

[0045] (1) Mix 40g of copper anode slime and 20g of melting agent NaOH evenly, place it at the bottom of a special crucible, send it to a muffle furnace, and smelt it at 500°C for 60min to obtain a smelted product.

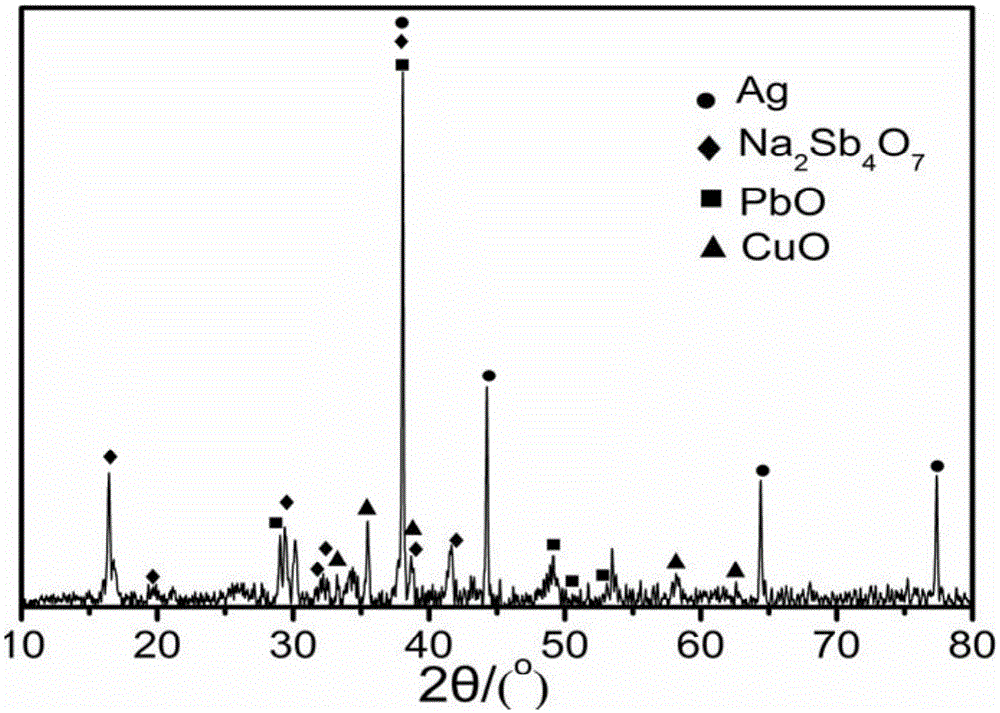

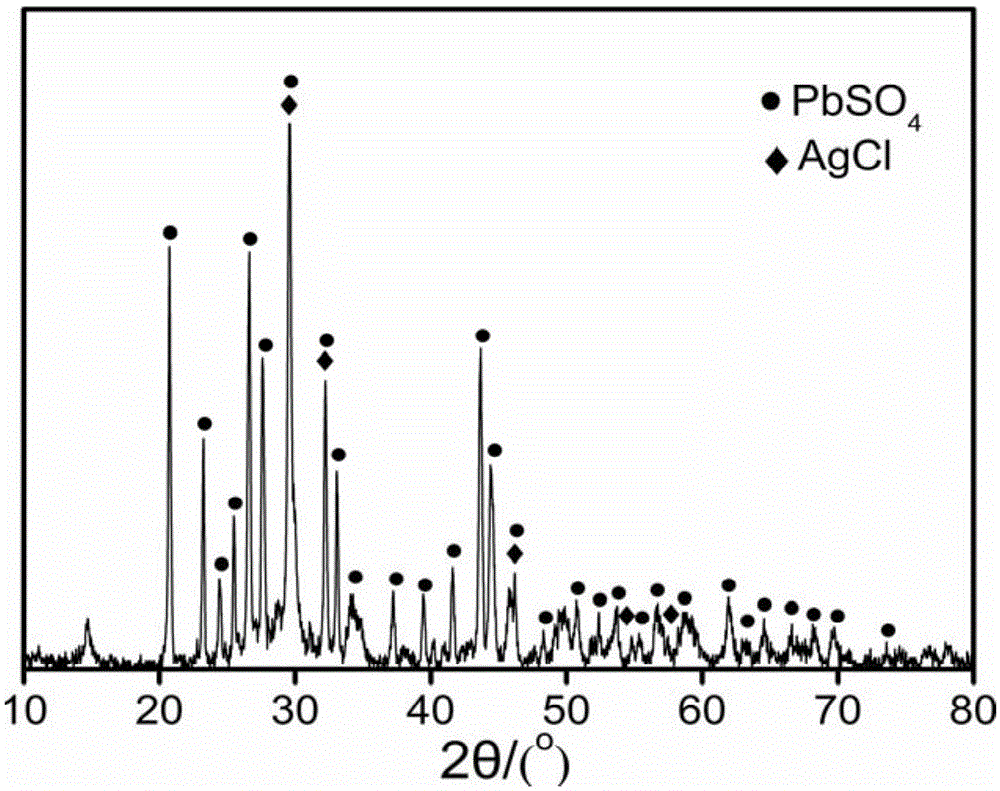

[0046] (2) Cool and crush the smelted product, add 500mL of water, shake at 60°C for 60min (frequency 2-3s -1 ), filtered to obtain alkaline leaching solution and alkaline leaching residue. The leaching rates of selenium and arsenic are 95.79% and 96.83%, respectively. Almost all of selenium and arsenic enter the leaching solution, while the leaching rates of copper, lead, antimony and tellurium are only 0.06%, 2.41%, 0.72% and 0.67%, respectively. Silver and other precious metals are enriched in the alkaline leaching slag (see XRD for the alkaline leaching s...

Embodiment 2

[0049] A method for separating and enriching valuable metals from copper anode slime according to the present invention, its process flow chart is as follows figure 1 shown, including the following steps:

[0050] (1) Mix 40g of copper anode slime and 20g of melting agent NaOH evenly, place it at the bottom of a special crucible, send it to a well-type resistance furnace, and melt it at 500°C for 60min to obtain a smelted product.

[0051] (2) Cool and crush the smelted product, add 500mL of water, shake at 70°C for 60min (frequency 2-3s -1 ), filtered to obtain alkaline leaching solution and alkaline leaching residue. The leaching rates of selenium and arsenic are respectively 96.12% and 97.33%. Almost all of selenium and arsenic enter into the alkaline leaching solution, while the leaching rates of copper, lead, antimony and tellurium are 0.14%, 3.52%, 0.89% and 0.92%, respectively. Silver and other precious metals are enriched in the alkaline leaching slag; quicklime is a...

Embodiment 3

[0054] A method for separating and enriching valuable metals from copper anode slime according to the present invention, its process flow chart is as follows figure 1 shown, including the following steps:

[0055] (1) Mix 40g of copper anode slime and 40g of melting agent NaOH evenly, place it at the bottom of a special crucible, send it to a muffle furnace, and smelt it at 600°C for 60min to obtain a smelted product.

[0056] (2) Cool and crush the smelted product, add 500mL of water, shake at 70°C for 60min (frequency 2-3s -1 ), filtered to obtain alkaline leaching residue and alkaline leaching solution. The leaching rates of selenium and arsenic are respectively 97.10% and 97.64%. Almost all of selenium and arsenic enter the leaching solution, while the leaching rates of copper, lead, antimony and tellurium are 2.05%, 4.83%, 1.36% and 1.22%, respectively, which are comparable to those of gold and silver. and other precious metals are enriched in the alkaline leaching slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com