Artificial bed stone and gravity separation method for complex ores

A man-made, bedrock technology, applied in the bedrock field, can solve the problems of low ore beneficiation technical indicators in the whole process, large fluctuation of concentrate enrichment ratio, and large changes in valuable metal content, and achieves high separation efficiency and raw ore treatment. The effect of cost reduction and reduction of metal loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

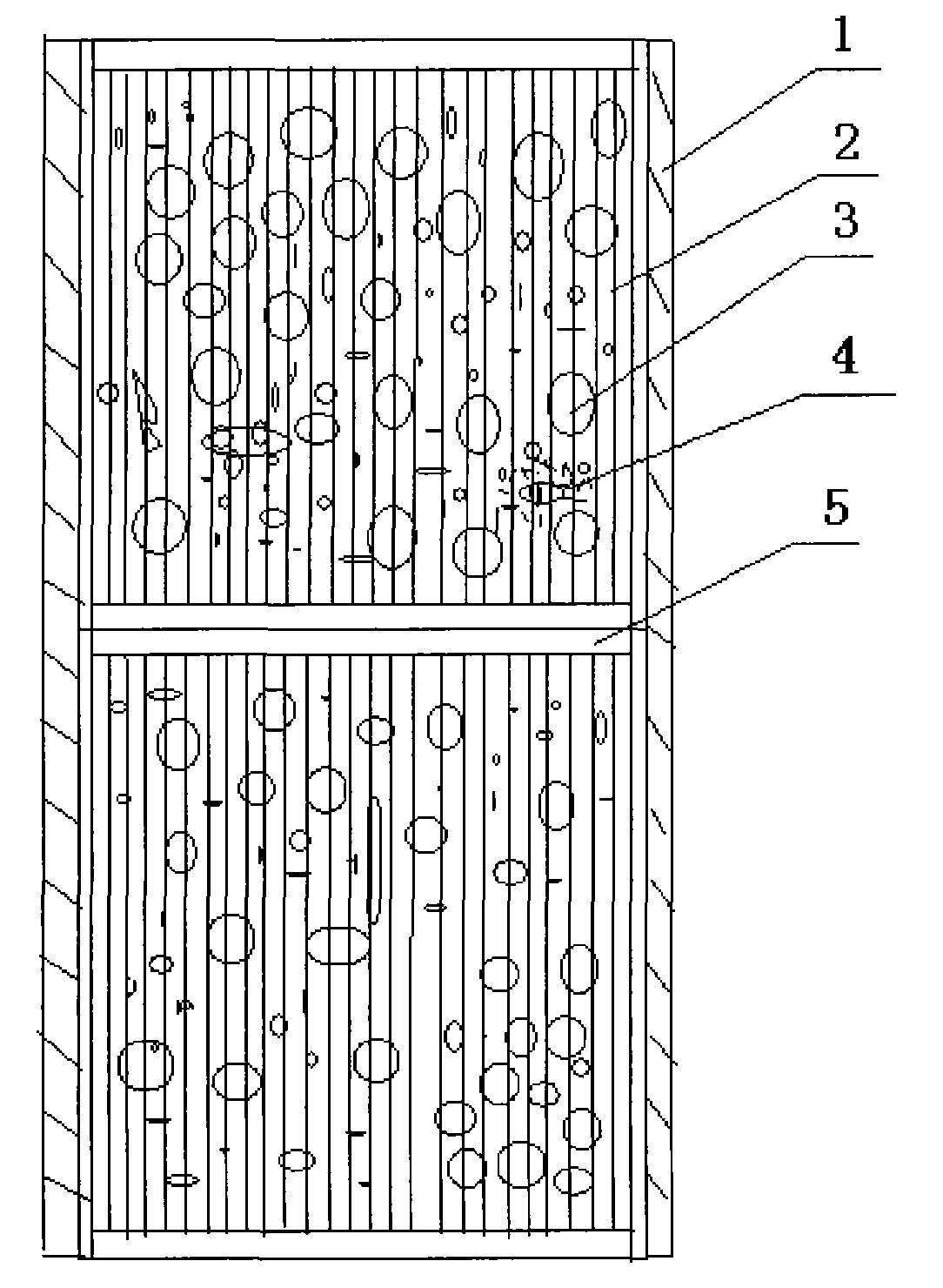

[0023] Using an ordinary ironmaking furnace, 20 kg of iron ore or iron slag containing 20% iron by mass in advance, mixed with 30 kg of glass powder and 40 kg of pottery clay, placed in the ironmaking furnace, at 1150-1200 °C Calcined at high temperature to make it reach a molten state, then immediately pour it into a spherical or ellipsoidal mold, and cool to obtain an artificial bed stone.

Embodiment 2

[0025] Using an ordinary ironmaking furnace, place 30 kg of iron slag containing 30% iron in mass content, 30 kg of kaolin, and 40 kg of river sand in advance in the ironmaking furnace, and calcinate at a high temperature of 1250-1300 ° C to achieve melting state, then immediately pour it into a spherical or ellipsoidal mold, and cool to obtain an artificial bed stone.

Embodiment 3

[0027] Using a common ironmaking furnace, 40 kg of iron ore with a mass content of 40% iron, 20 kg of glass powder, 35 kg of pottery clay, and 5 kg of river sand are placed in the ironmaking furnace in advance, at 1200-1300 It is calcined at a high temperature of ℃ to reach a molten state, and then immediately poured into a spherical or ellipsoidal mold and cooled to obtain an artificial bed stone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com